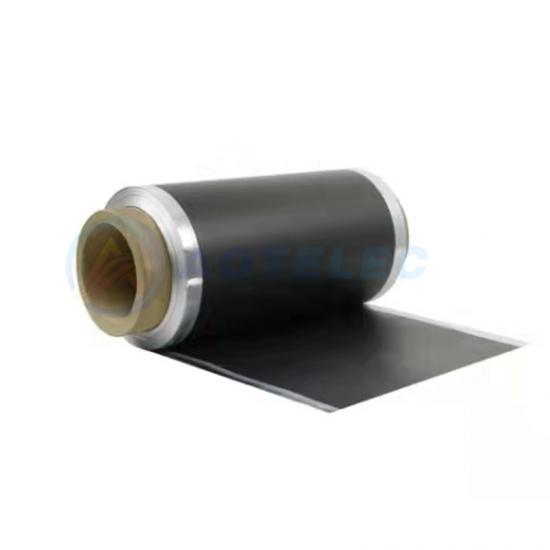

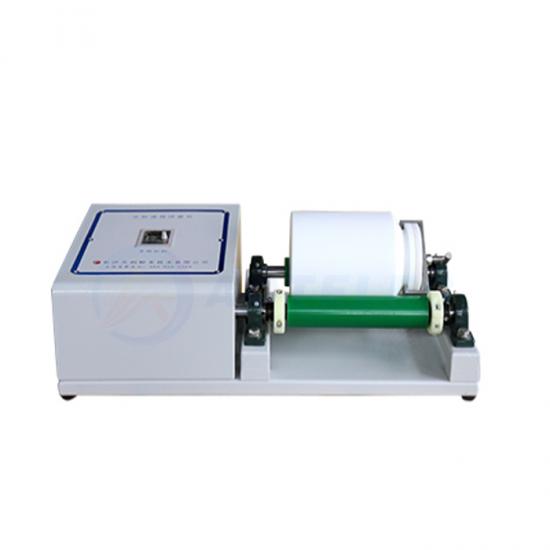

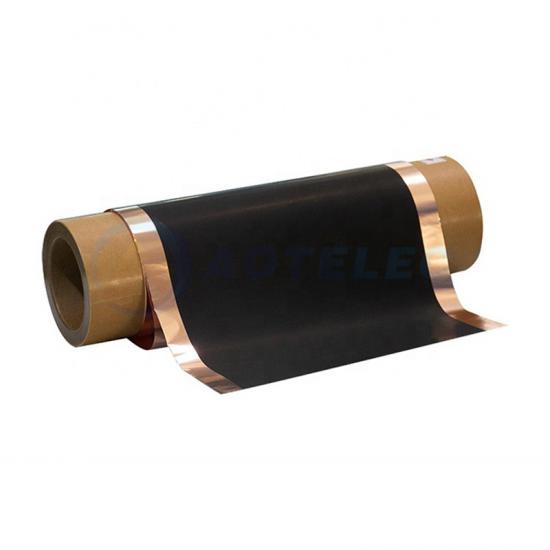

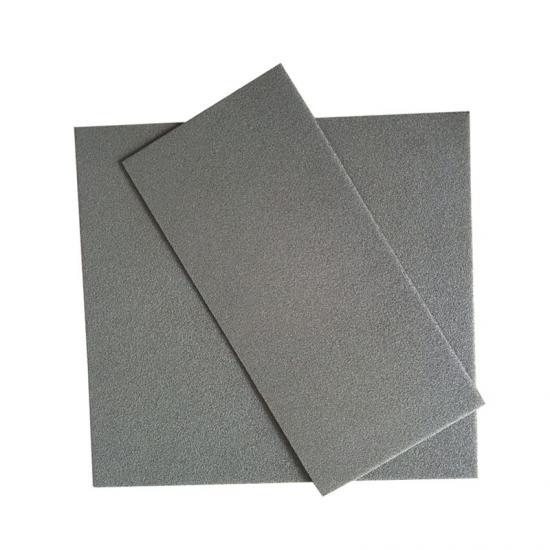

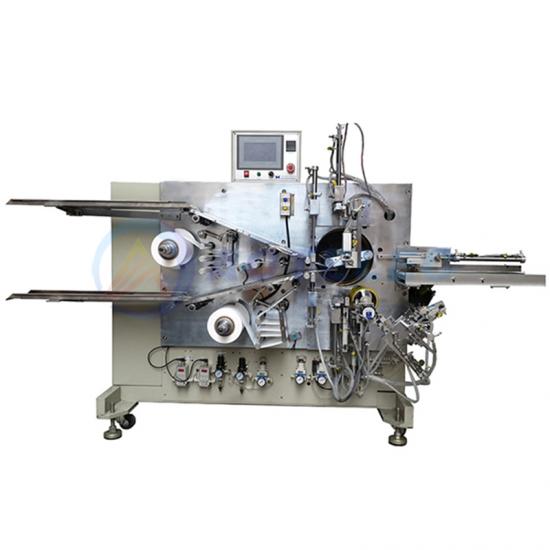

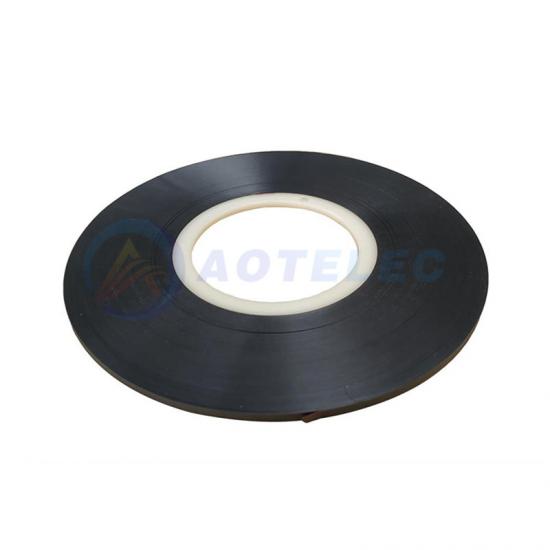

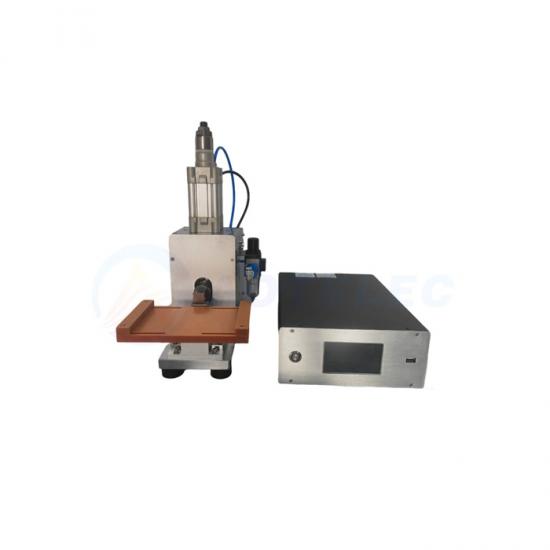

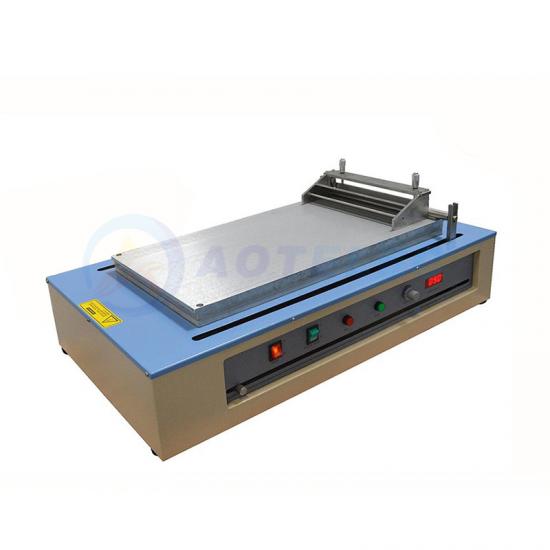

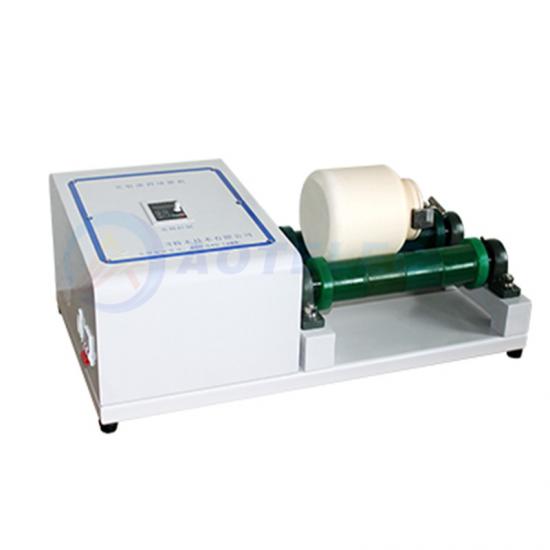

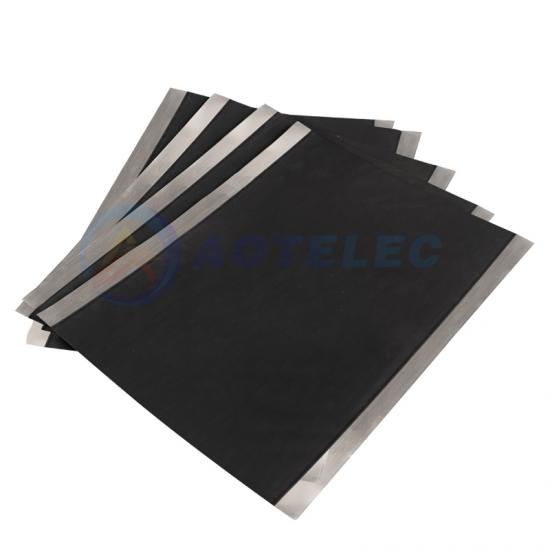

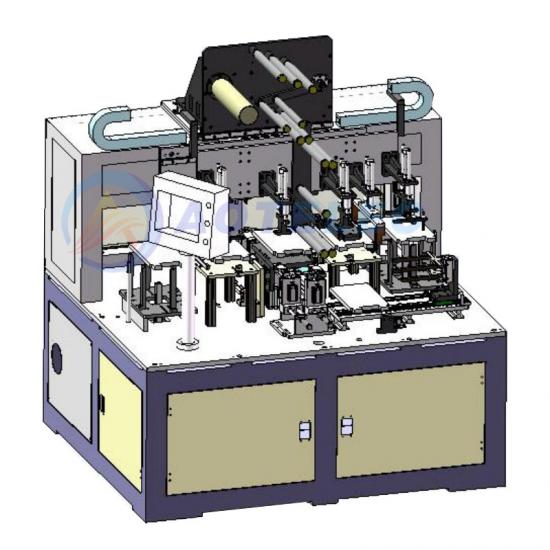

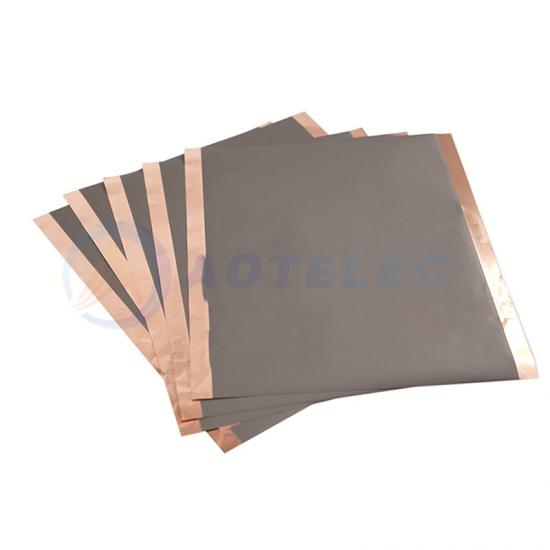

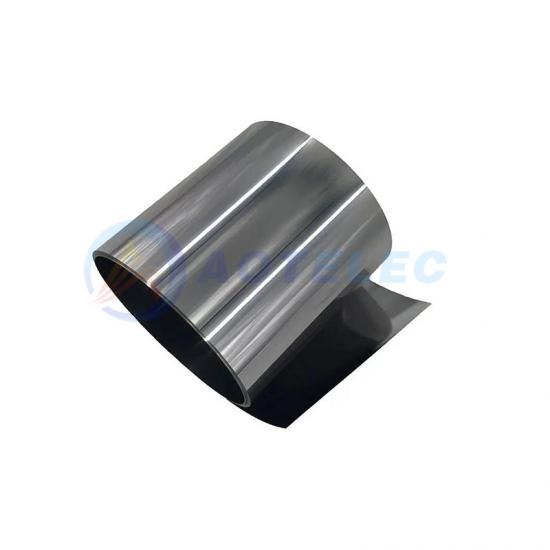

The Vertical Double Side Coating Machine is a core equipment for the manufacturing of lithium battery electrode sheets. It is specifically designed for performing synchronous double-sided coating operations on electrode substrates (such as copper foil and aluminum foil), serving as a crucial process equipment that connects the pre-treatment of the substrate with the drying of the electrode sheet. Its core function is to evenly coat the positive and negative electrode pastes on both sides of the substrate, forming an active material layer that meets the thickness requirements, providing the basic structure for battery energy storage and conduction.

Core feature

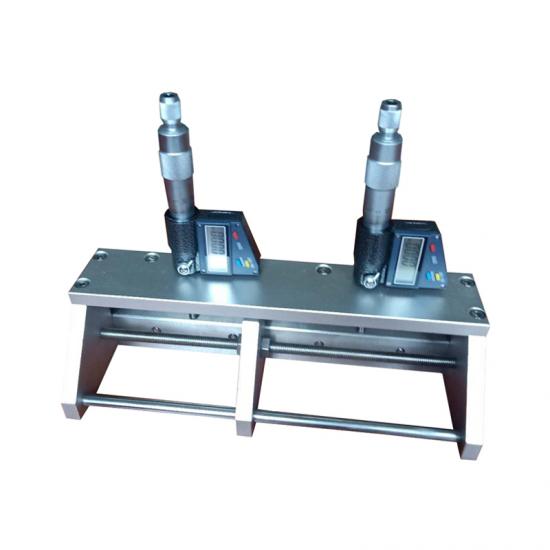

1.Double-sided synchronous coating without the need for secondary flipping processing. The thickness consistency error is ≤ ±2 μm, significantly improving production efficiency.2.With a vertical coating architecture and a high-precision extrusion coating head, it can effectively avoid issues such as slumping of the slurry and residual bubbles.

3.Equipped with an intelligent tension control system and an online thickness monitoring module, it can adjust the coating parameters in real time, adapting to different viscosities of the slurry and substrate specifications.

4.The equipment has strong operational stability, supports continuous production, and is convenient for type change and adjustment, meeting the diverse needs of power, energy storage, and consumer lithium batteries.

Core function

1.Ensuring the uniformity and consistency of the coating on the electrode sheet, which directly affects the capacity, cycle life, and safety performance of the battery.The double-sided synchronous processing mode shortens the production process.

2.substrate damage, and significantly improves the production line capacity and product qualification rate.

3.Precisely controlling the coating thickness and surface density helps the battery achieve high energy density and lightweight design, meeting the performance requirements of various lithium battery applications.

SPECIFICATIONS:

|

Working Power |

AC 208 - 240 V 50/60Hz, Single Phase 2 KW (15A Air breaker required) |

|

Coating Method

|

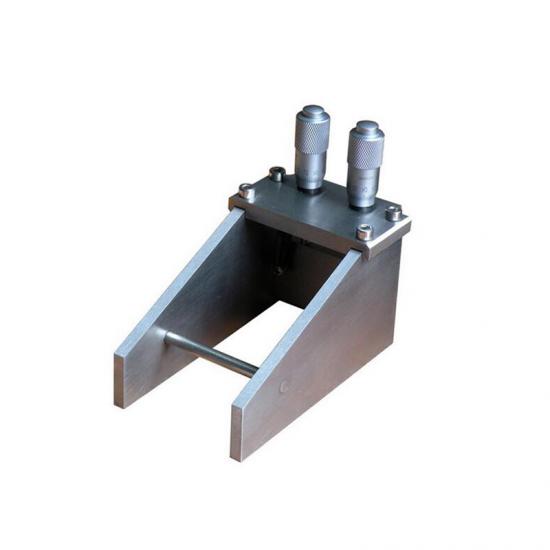

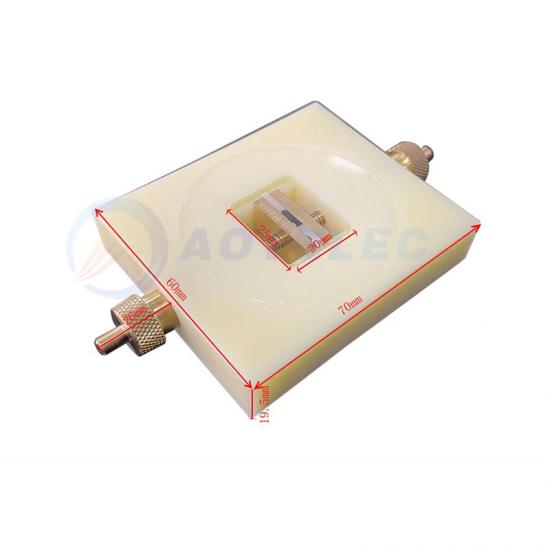

Slot Dies technique Coating Thickness Precision: +/- 0.003 mm The coating thickness precision depends on the coating material. Coating film width: 0.1 mm |

|

Max. Coating Width |

250 mm |

|

Max. Coating Speed |

800 mm / min |

|

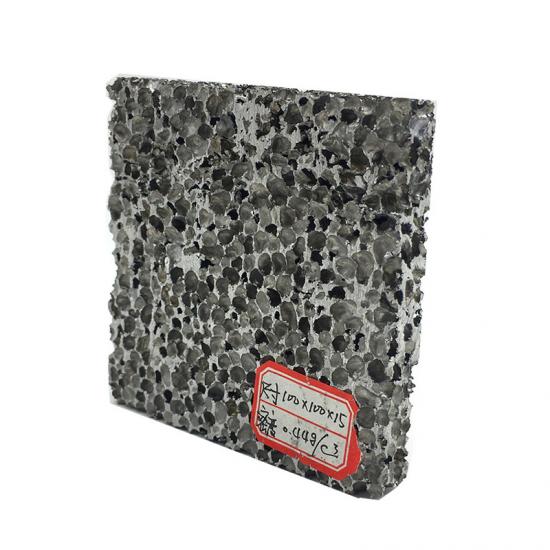

Coating Thickness Range |

3 - 50 um For most kinds of battery electrode coating materials It depends on the wire rod, the physical property of the coating material, substrates, and coating speed |

|

Coating Thickness Precision |

+/- 0.003 mm The coating thickness precision also depends on the coating materials (Viscosity, Solid contents, surface tension and etc) |

|

Wire rod dimensions |

Diameter: 10 mm; Length: 400 mm; Wet coating thickness references: 6 um, 8 um, 10 um, 12 um, 15 um, 20 um, 25 um, 30 um, 40 um, 50 um, 60 um, 70 um, 80 um, 100 um, 120 um, 150 um, 200 um |

|

Drying |

IR; Infrared heating Adjustable Venting: Maximum 403 m^3/h Maximum heating temperature: 120°C Temperature Accuracy: ± 1°C Heating Zone Length: 425 mm |

|

Reeling/Unreeling Shaft |

75 mm (I.D.) |

|

Max. Reeling/Unreeling Diameter |

300 mm (O.D.) |

|

Max. Coating Length |

Depending on the coating and substrate thickness. Typically, 10um thick foil with 100um coating can get 600 meters of electrode length coated per run |

|

Exhaust Port Size |

127mm O.D. |

|

Product Dimensions |

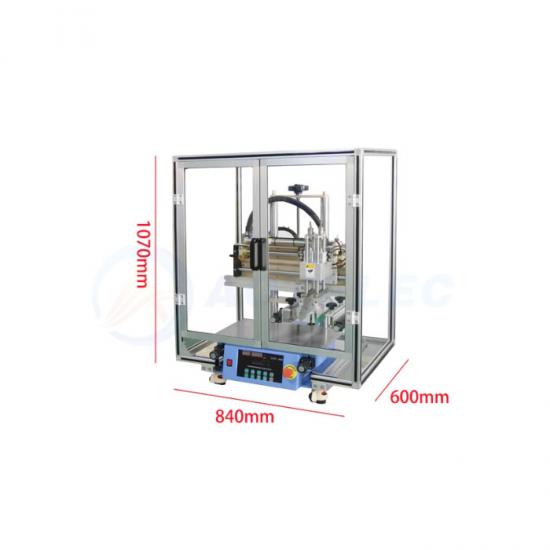

1100 mm (L) x 1000 mm (W) x 1750 mm (H) |

|

Compliance |

CE Certified |

|

Warranty |

One Year limited warranty with lifetime support Rusting and damage due to improper storage condition or maintenance are not covered by warranty |

|

Net Weight |

530kg |

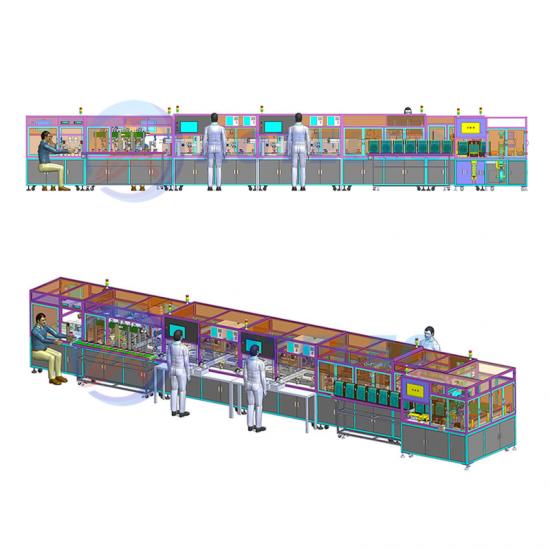

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1:How long do you need to prepare my goods?

A: 3-5 days for battery materials. 5-25 days for equipment (based on different model and quantities).

Q2:Can we have our logo or company name to be printed on products or package?

A: Sure. your logo could be printed on your products by hot stamping, printing, embossing, UV coating, silk-screen printing or sticker. In order to explore the market better and provide more convenient services to global customers, we sincerely invite overseas agent to create bright future together.

Q3:How can I install and operate the machine by myself?

A: Our system R&D based on integrated development view. when you get the machine, just need to connect it with the electrical power, then machine can be working. because the English software were installed in this machine. what you need to do is only learning the software usage, and the complete English user manual will be coning to you with the machine.

Q4:How to get technical support after purchasing?

A: Our factory provide online technical support in English , you can easy catch us online by Skype, Wechat, and Email, if you need any remote assistant support, then we will support you though Team Viewer.

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported