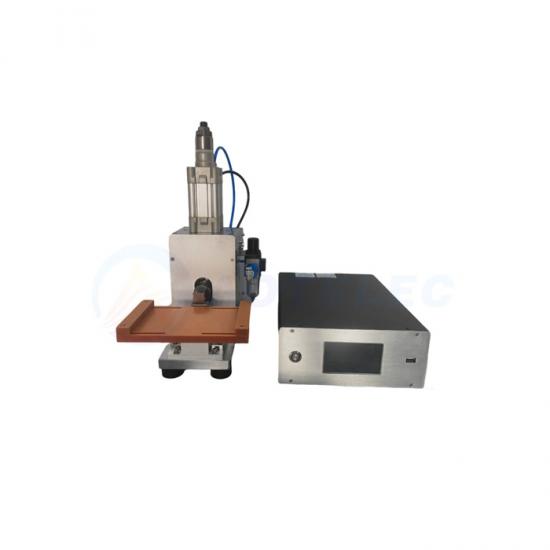

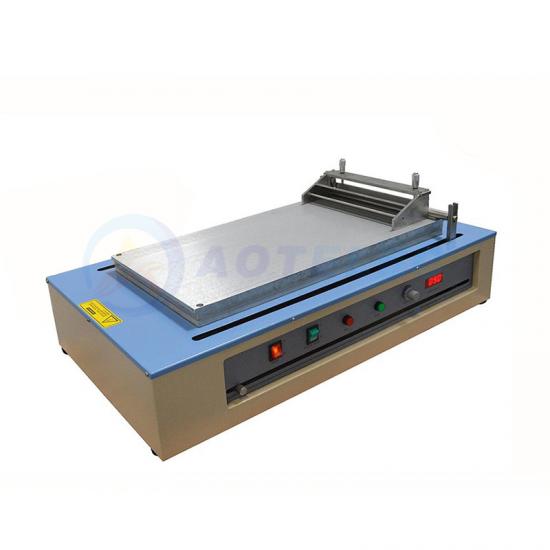

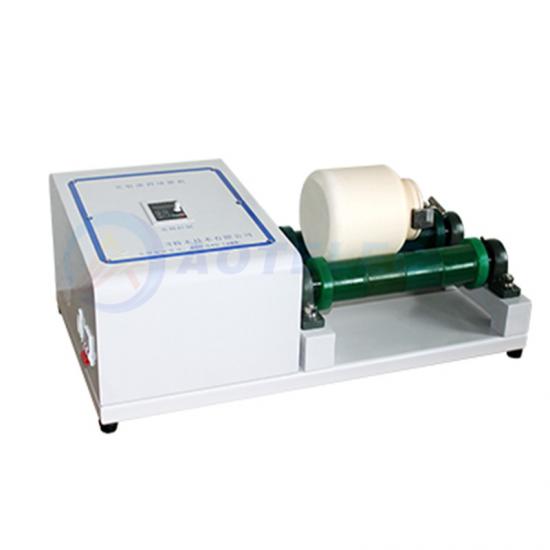

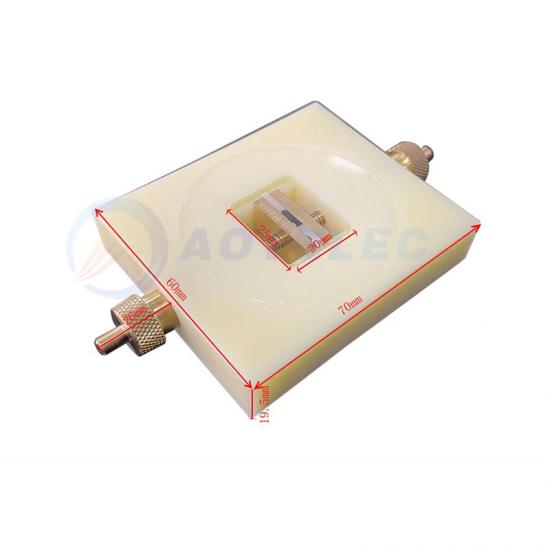

AOT-QFZ is a coating adhesion tester is used to measure the adhesion ability of various coating films to the surface of the object to be coated.

The adhesion performance of the paint film was measured by the circle track method, and the integrity of the paint film within the scratch range of the circle rolling line was used to evaluate the adhesion of the paint film to the substrate according to seven grades.

|

Product Name |

Coating Adhesion Tester |

|

|

Product Model |

AOT-QFZ |

AOT-QFD |

|

Graphical way |

Manual |

Electric |

|

diameter of the drawn figure |

0-10.5mm |

|

|

Workbench Effective Stroke |

80mm |

|

|

Effective area of workbench |

50*120mm |

|

|

weighted weights |

500g 200g 100g |

|

|

Motor speed |

- |

80r/min |

|

Dimensions |

330×160×220mm |

420×170×270mm |

|

Weight |

15kg |

24kg |

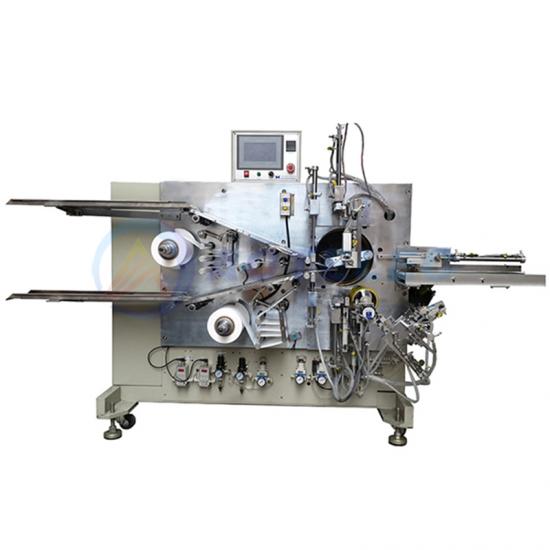

How to use QFZ coating adhesion tester:

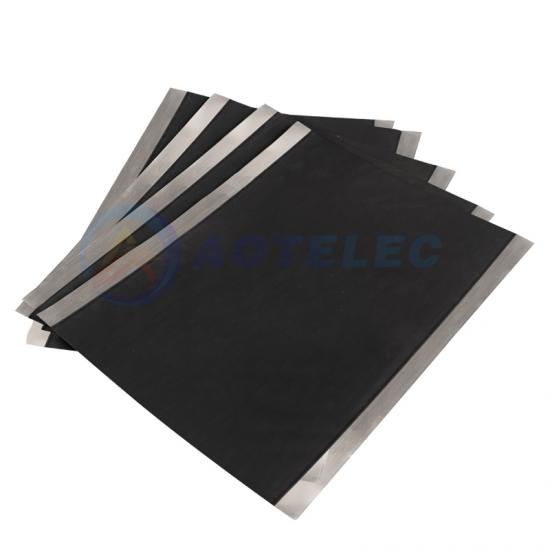

1. Prepare samples according to the requirements.

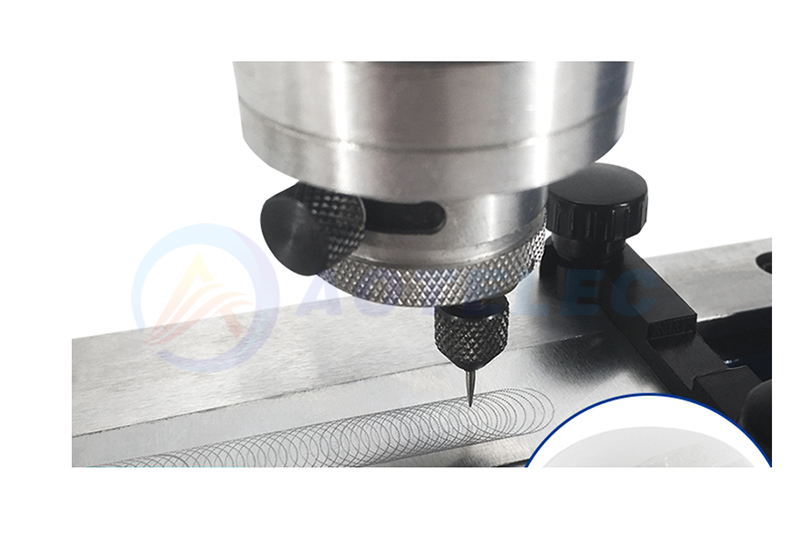

2. Check the steel needle and replace it with a new steel needle at the beginning of use. The needle tip is about 3 mm away from the work surface.

3. Adjust the eccentric position of the needle tip according to the required drawing diameter, and then tighten it with screws.

4. Put the prepared sample with the coating film facing up and install it on the workbench and press it tightly with a pressure plate.

5. Add weights on the weight plate according to the regulations.

6. Lift the movable half nut to move the workbench to the outer end, and then put down the movable half nut.

7. Turn the pressure lever to make the needle tip contact with the membrane surface.

8. Shake the hand wheel, and the steel needle will draw a spiral pattern on the sample plate. According to the pattern, the adhesion of the coating film can be judged as excellent, good, medium, poor, and poor.

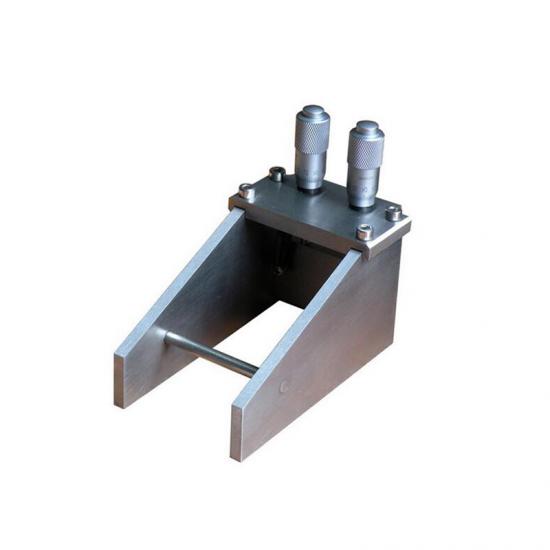

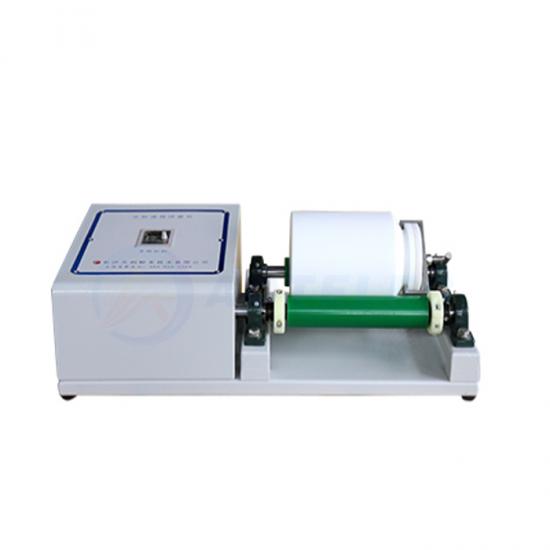

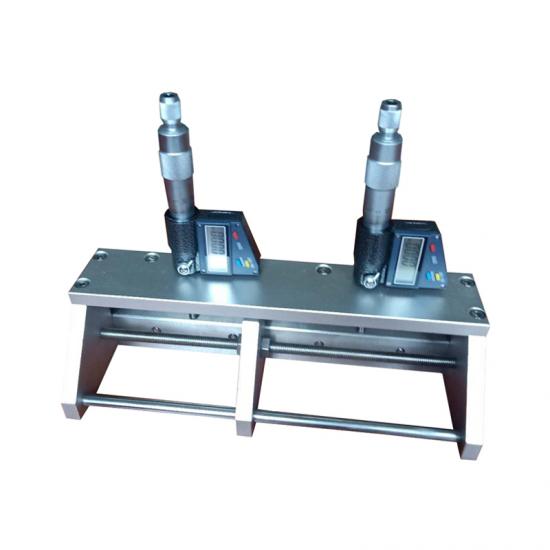

Structural principle of paint film adhesion tester:

1. The main transmission part is composed of a hand wheel, a sprocket, and a helical helical gear. When the hand wheel is turned, the worktable moves left and right, and the needle is drawing a circle at the same time.

2. The drawing head is composed of the following two components.

A. The double-headed square screw is used to adjust the machine head up and down.

B. The drawing diameter is adjusted by connecting the lower dovetail plate with a sliding dovetail and a screw that can drive the hand tracing needle.

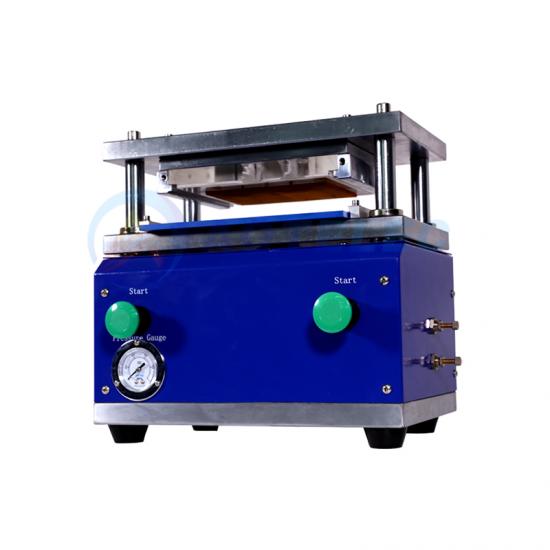

3. The workbench part is connected with the lead screw with a movable half nut at one end to drive the workbench to move back and forth. There are four nuts and two pressure plates on the workbench for pressing and releasing the test piece.

4. The base part is used to support the workbench and tracing hea.

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported