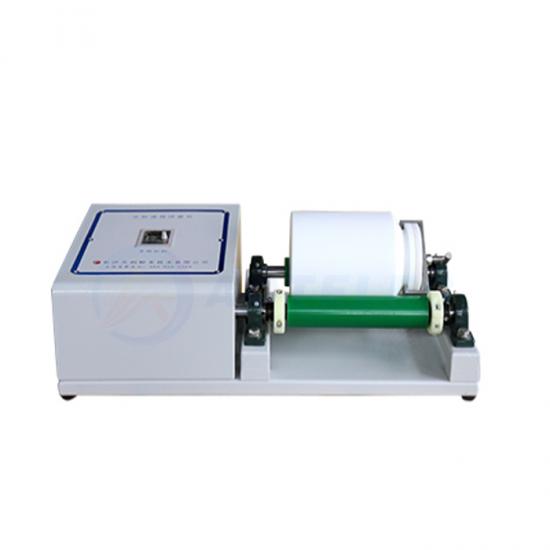

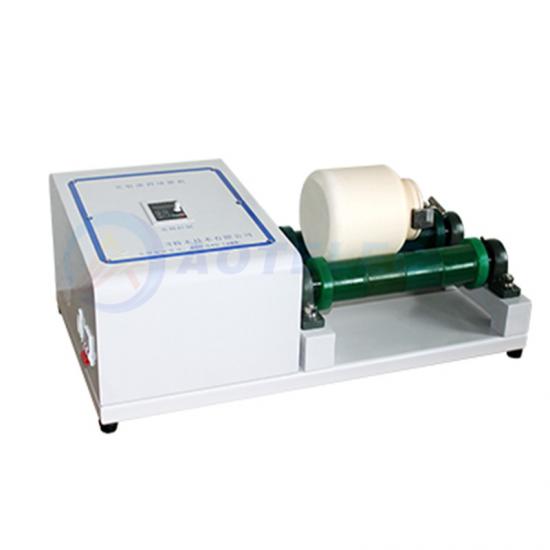

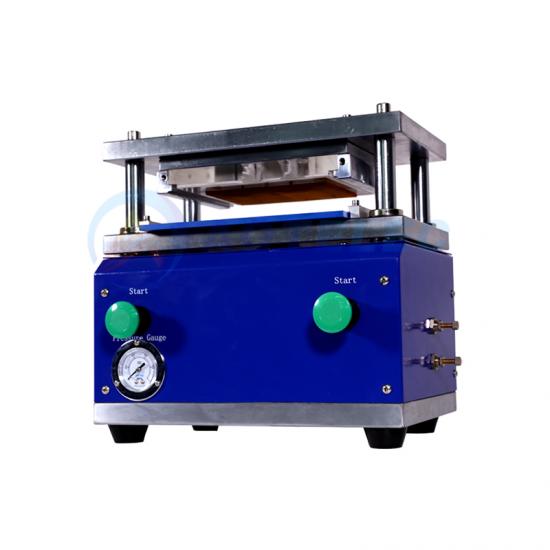

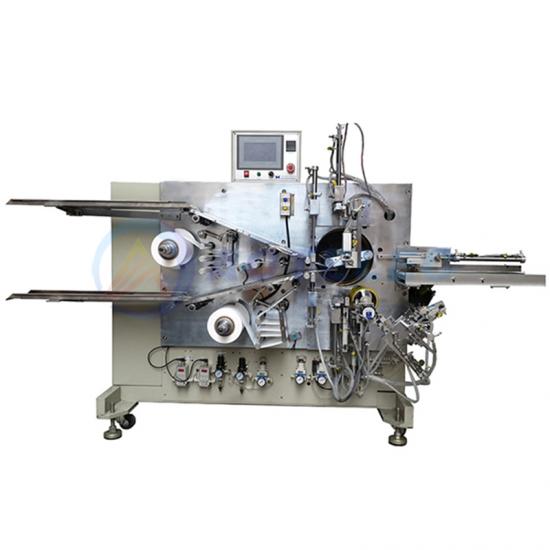

1. Product brief introduction:

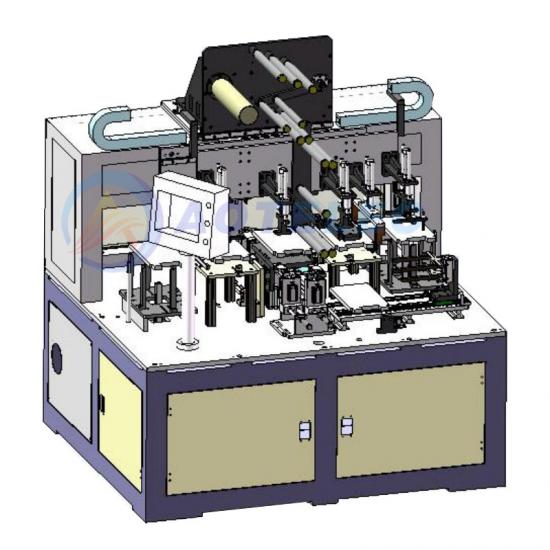

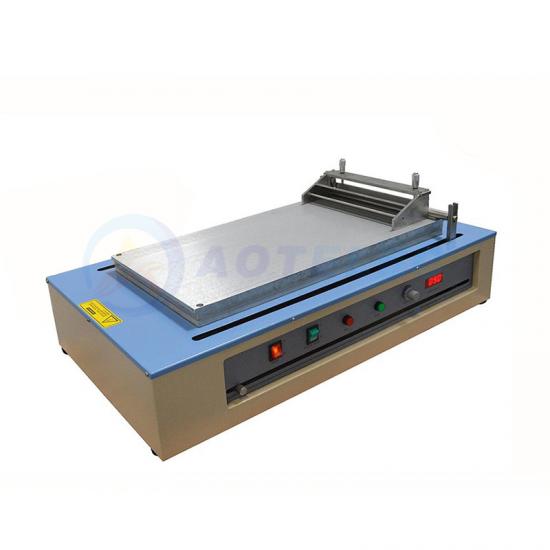

Experimental/lightweight roller ball mill is an ultrafine grinding and mixing equipment used in laboratories and small-scale production. This machine is beautiful and novel, with a compact structure, easy operation, high work efficiency, and uniform grinding of fine particles. It is the preferred equipment for scientific research, teaching, experimentation, and production. It can be widely used in industries such as electronic materials, magnetic materials, biomedicine, ceramic glazes, metals, non metals, and new materials.

2.Principle of the product

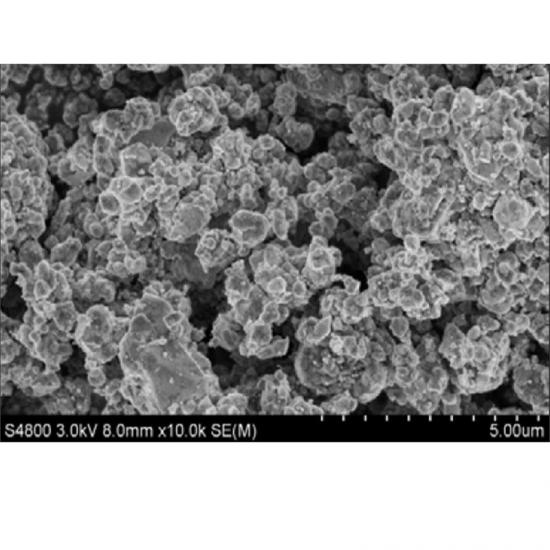

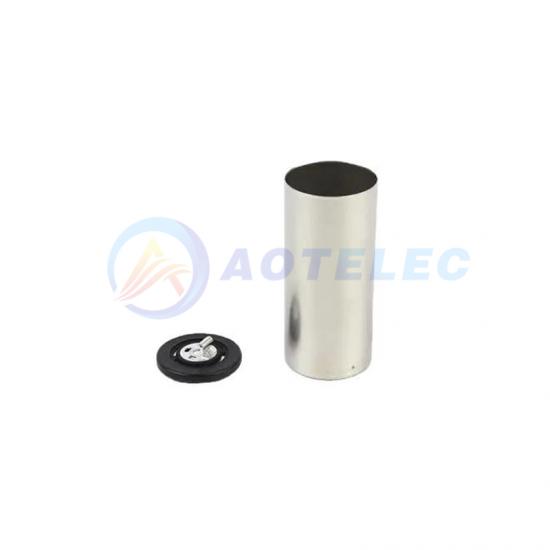

When the ball mill is working, the grinding medium and material inside the cylinder are lifted to a certain height together with the rotation of the cylinder. Due to gravity, they detach from the cylinder wall and fall along a parabolic path. The material is crushed under the impact of the grinding medium and the friction and shear caused by the rolling and sliding of the grinding medium.

3. Features:

1. The machine has a compact structure and is easy to operate;

2. High work efficiency and uniform grinding of fine particles;

3. By adjusting the driven rubber roller, ball milling jars with different outer diameters within a certain range can be used;

4. Easy to change cans, capable of dry and wet grinding;

4. Product usage precautions:

1. It is strictly prohibited to start with overload;

2. During operation, it is required to handle with care and stop the machine immediately in case of any abnormalities;

3. The ball milling rate should not exceed 70% of the effective volume of the grinding cylinder; When the ball packing density is too high (such as steel balls) to rotate, consideration should be given to reducing the ball packing rate;

4. Before grinding, the cover of the ball grinding cylinder must be tightly sealed without leakage;

5. The electrical part should be kept dry and ventilated to avoid short circuits and burns;

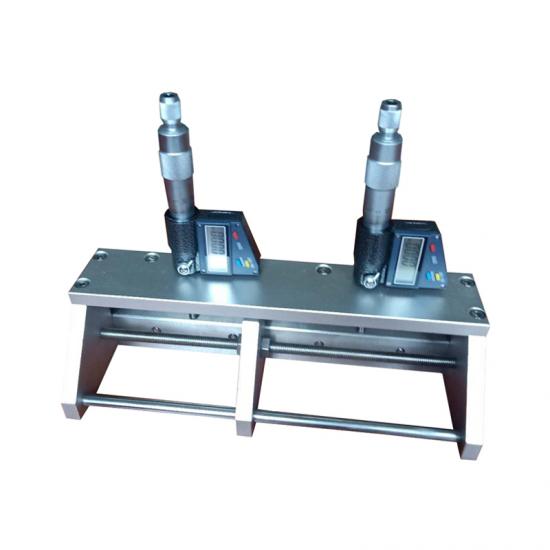

When the size of the grinding cylinder changes, adjust the driven rubber rod (preferably at an angle of about 120 degrees with the two rubber rollers), pay attention to the parallelism of the two axes when adjusting, and ensure that the ball mill cylinder rolls smoothly without derailing or moving towards one end;

|

Name |

POT MILL |

|

|

Model |

AOT-GQM-2-15 |

|

|

Main Motor |

Power |

1.1 KW |

|

Brand |

DEDONG |

|

|

Roller speed |

400 (r/min) |

|

|

Length of roller |

800 mm, effective length 762mm, |

|

|

Distance between two roller |

Adjustable, max is 370mm |

|

|

Work Station |

2 PCS |

|

|

Roller Material |

Chrome-plated rod |

|

|

Dimension(mm) |

1130*550*760 |

|

|

Frequency Converter |

Power |

1.5 KW |

|

Brand |

DELIXI |

|

|

Weight |

130 Kg |

|

Company Profile

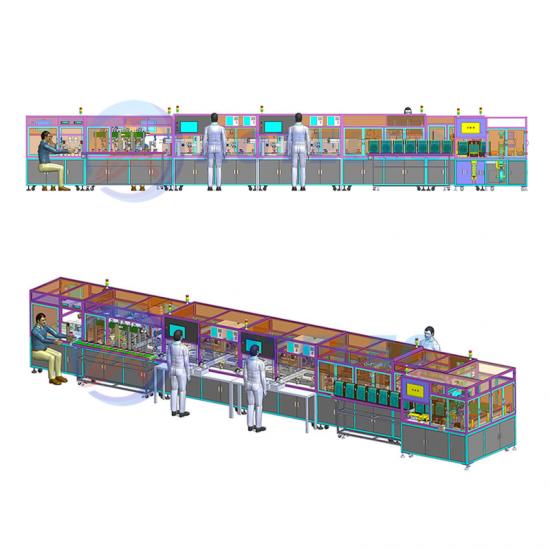

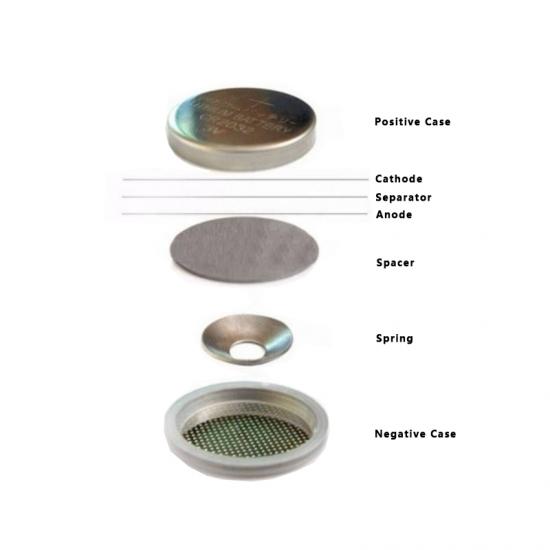

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1:How long do you need to prepare my goods?

A: 3-5 days for battery materials. 5-25 days for equipment (based on different model and quantities).

Q2:Can we have our logo or company name to be printed on products or package?

A: Sure. your logo could be printed on your products by hot stamping, printing, embossing, UV coating, silk-screen printing or sticker. In order to explore the market better and provide more convenient services to global customers, we sincerely invite overseas agent to create bright future together.

Q3:How can I install and operate the machine by myself?

A: Our system R&D based on integrated development view. when you get the machine, just need to connect it with the electrical power, then machine can be working. because the English software were installed in this machine. what you need to do is only learning the software usage, and the complete English user manual will be coning to you with the machine.

Q4:How to get technical support after purchasing?

A: Our factory provide online technical support in English , you can easy catch us online by Skype, Wechat, and Email, if you need any remote assistant support, then we will support you though Team Viewer.

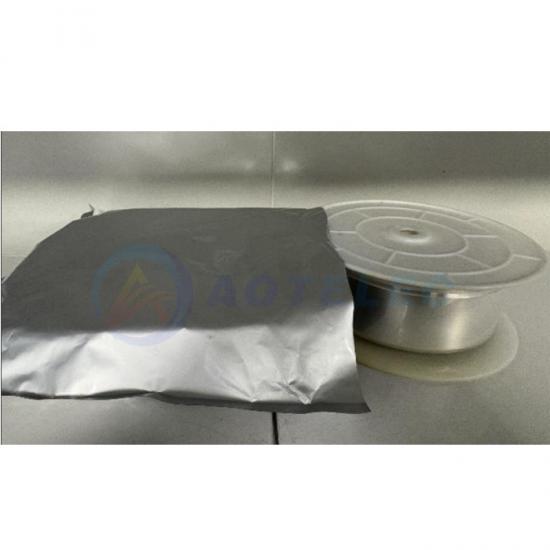

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported