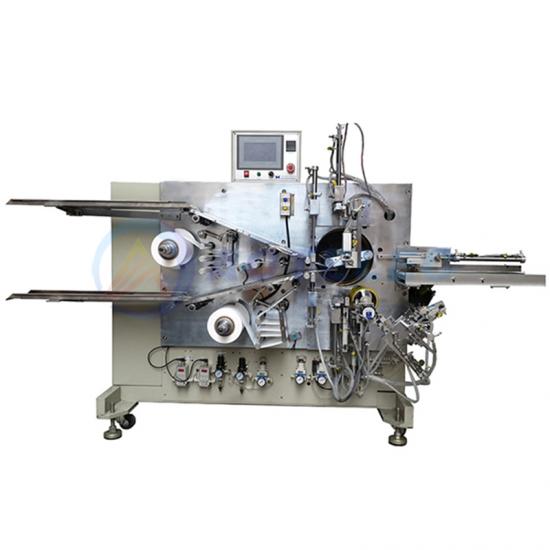

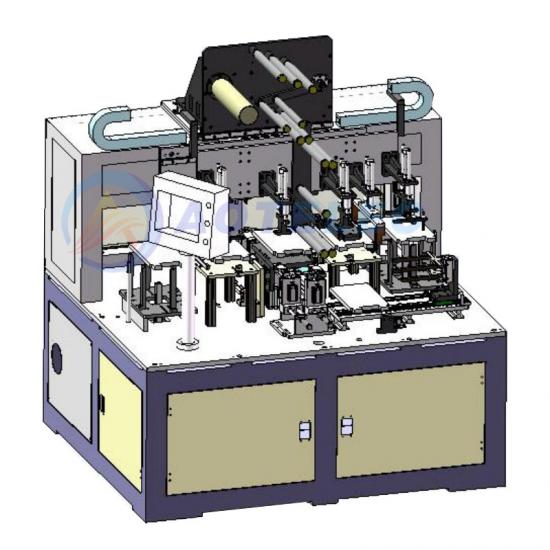

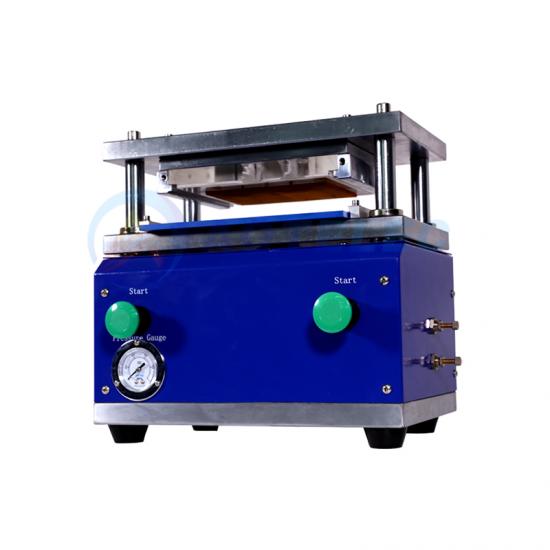

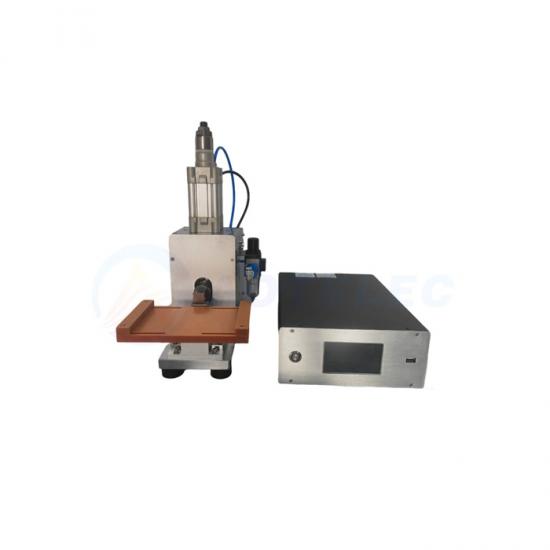

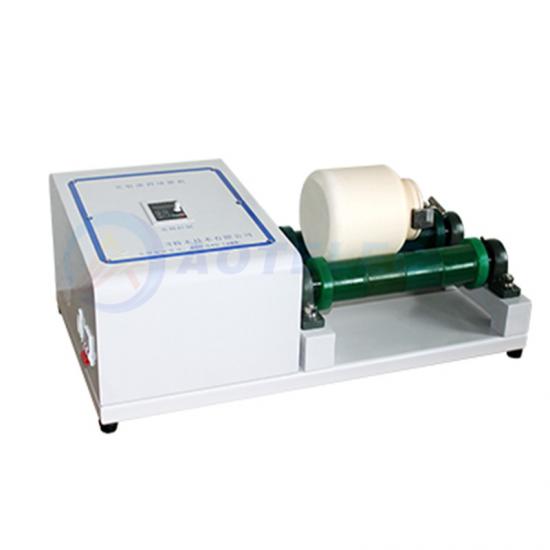

The Isostatic Pressing Machine is a crucial equipment in lithium battery production for optimizing the performance of electrodes and cells. It achieves material densification and interface adhesion through uniform pressure in all directions, directly enhancing the core indicators of the battery.

Core application scenarios

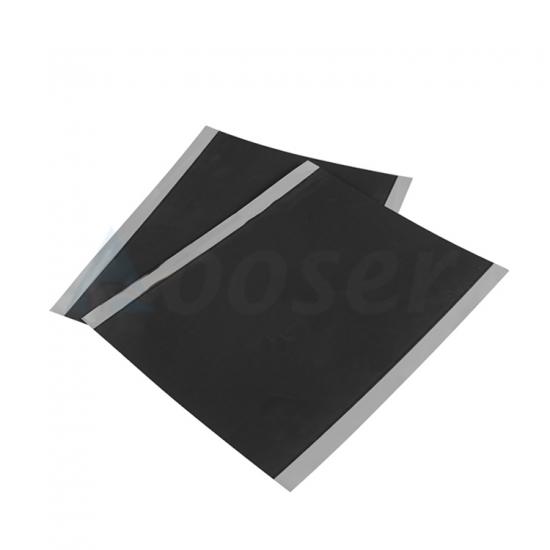

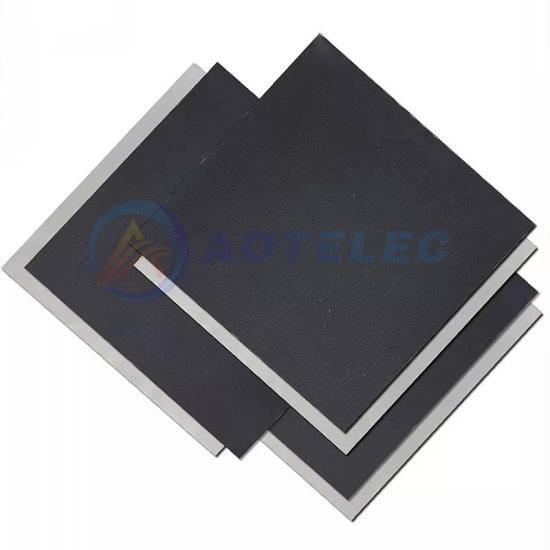

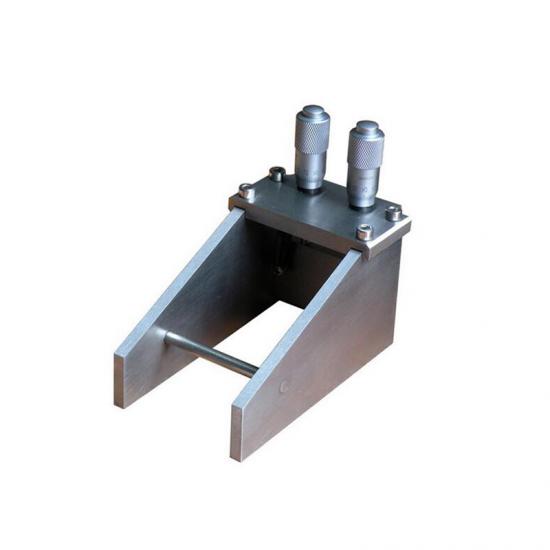

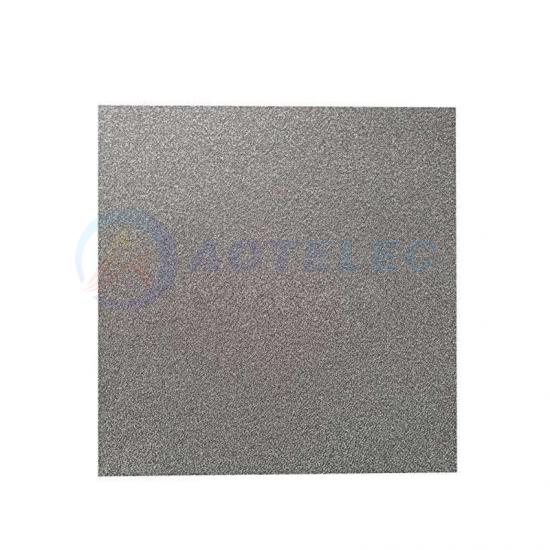

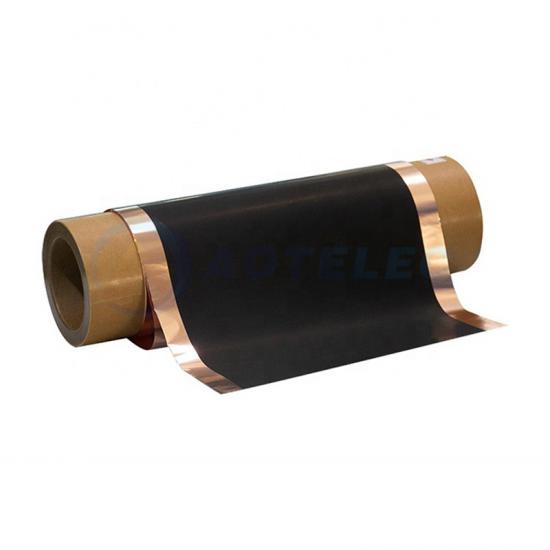

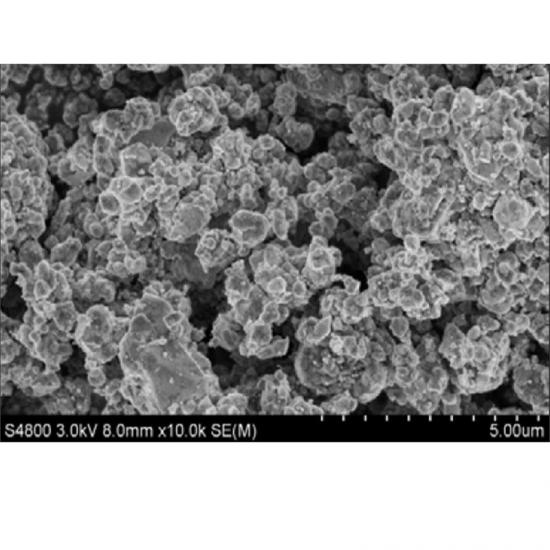

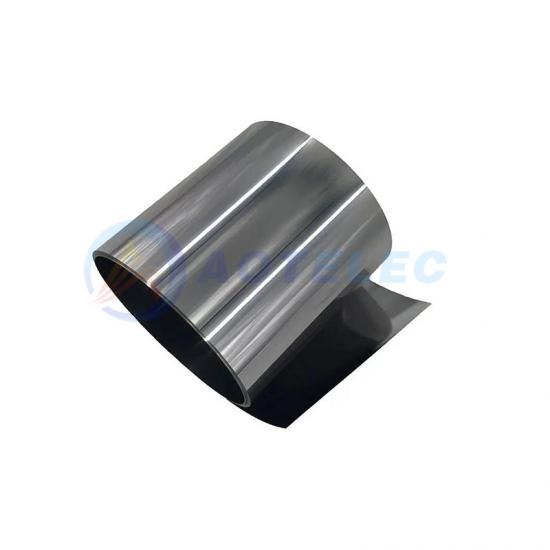

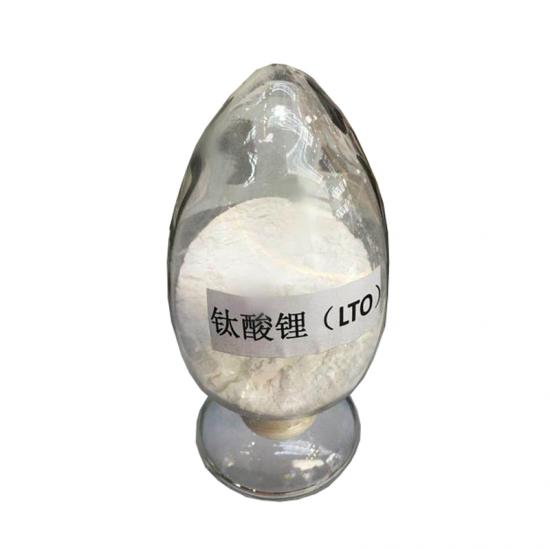

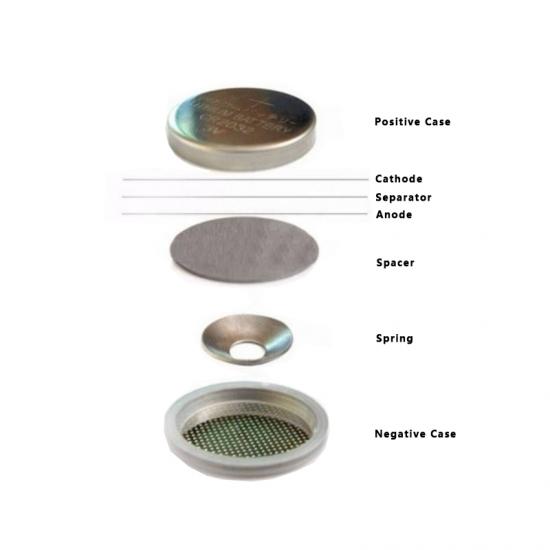

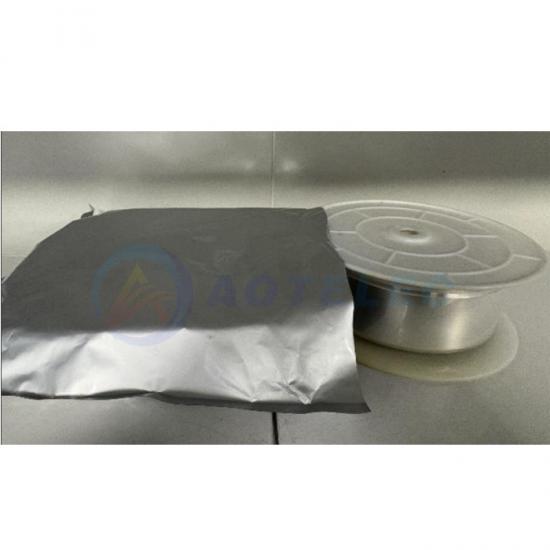

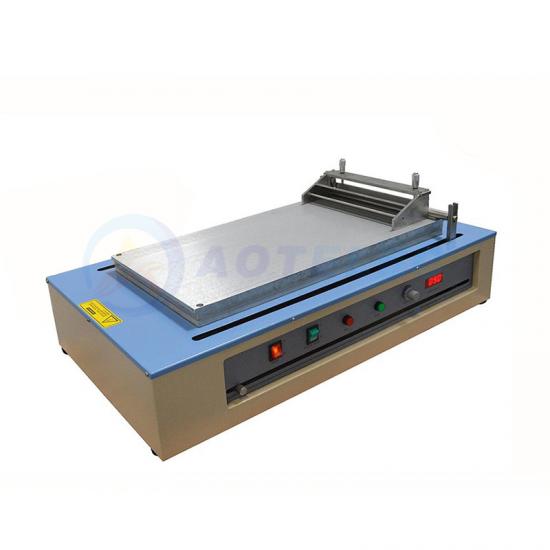

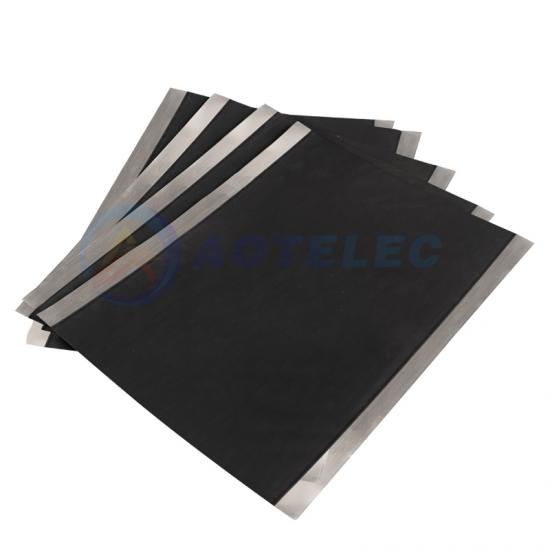

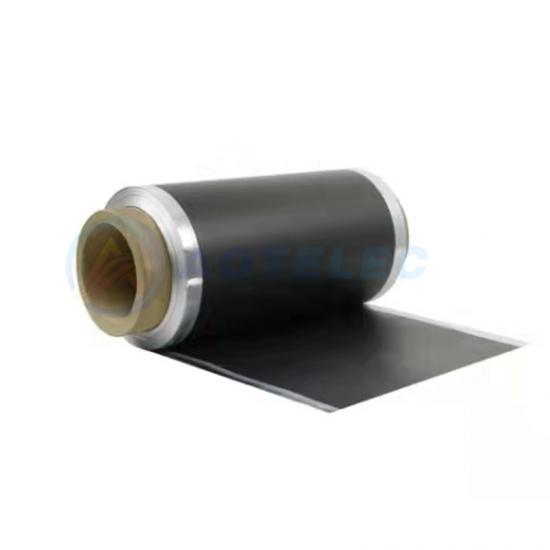

Electrode sheet pressing: The Isostatic Pressing Machine presses the positive electrode powders such as ternary and lithium iron phosphate, or the negative electrode powders such as graphite and silicon-based materials, to ensure uniform density of the electrode sheet and enhance the bonding force between the active substances and the current collector, avoiding local pores or detachment issues.

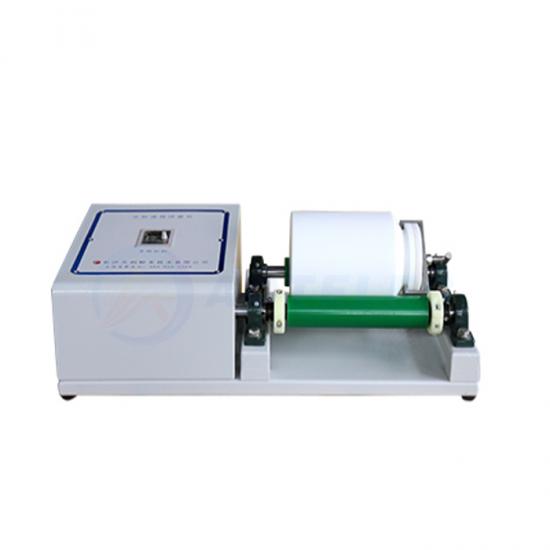

Densification after cell encapsulation: After the pouch or cylindrical lithium batteries are encapsulated, the Isostatic Pressing Machine applies uniform pressure to reduce the internal gaps of the battery cells and improve the space utilization rate, while reducing the risk of bulging during charging and discharging cycles.

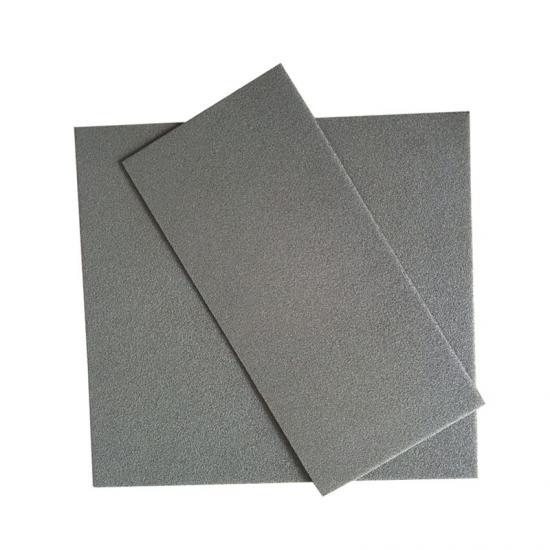

Solid-state lithium battery preparation: For solid-state electrolyte sheets or all-solid-state cells, the Isostatic Pressing Machine can achieve a close adhesion between the electrolyte and the electrode under mild conditions, reducing interface impedance and ensuring ion conductivity efficiency.

Core technical advantages

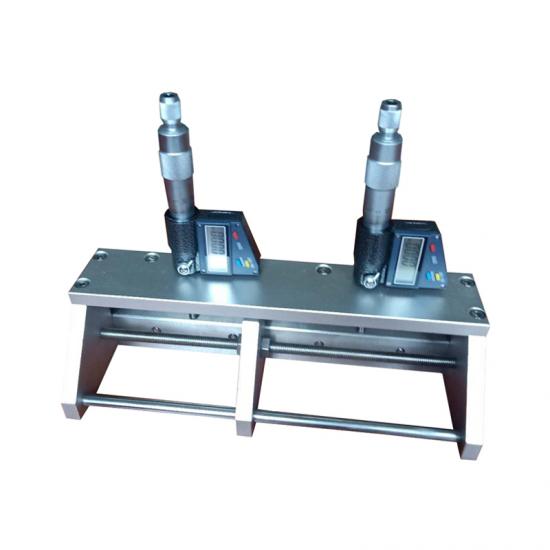

Uniform pressure control: The Isostatic Pressing Machine transmits a uniform pressure in all directions, avoiding the "edge effect" of traditional pressing, ensuring consistent performance of each part of the electrode or cell.

Versatile material compatibility: It can precisely match the pressing requirements of different active substances and binder systems, taking into account the hardness, toughness and other characteristics of different materials.

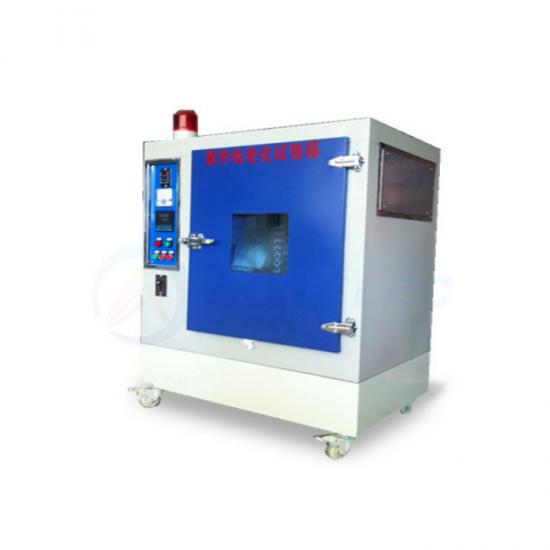

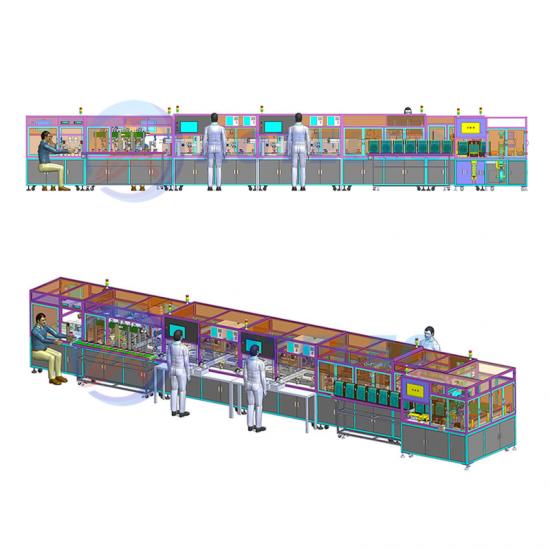

Flexible process adjustment: Parameters such as pressure and temperature can be precisely controlled, adapting to different scenarios ranging from laboratory small-scale research to factory large-scale production.

Parameters:

|

Model |

AOT-DJYP-20T |

AOT-DJYP-30T |

AOT-DJYP-40T |

AOT-DJYP-60T |

|

Pressure range |

0.2-20T / 0.1t |

0.3-30T / 0.1t |

0.5-40T / 0.1t |

1.0-60T / 0.1t |

|

Piston diameter |

95mm |

110mm |

130mm |

150mm |

|

Max piston stroke |

<30mm |

<40mm |

<50mm |

<50mm |

|

Control panel |

4.3 inch touch LCD screen |

|||

|

Pressure relief and pressurization method |

Electrically pressurized, gradual pressurization, automatic pressure replenishment, manual pressure relief |

|||

|

Hold pressure time |

Manually control |

|||

|

Pressure stability |

≤1.0MPa / 10min |

|||

|

Safety protection |

Bulletproof glass security door, leakage protection, emergency stop switch |

|||

|

Power source |

220V (50Hz/60Hz), 110V can be customized with extra fee |

|||

|

Max power |

400 W |

|||

|

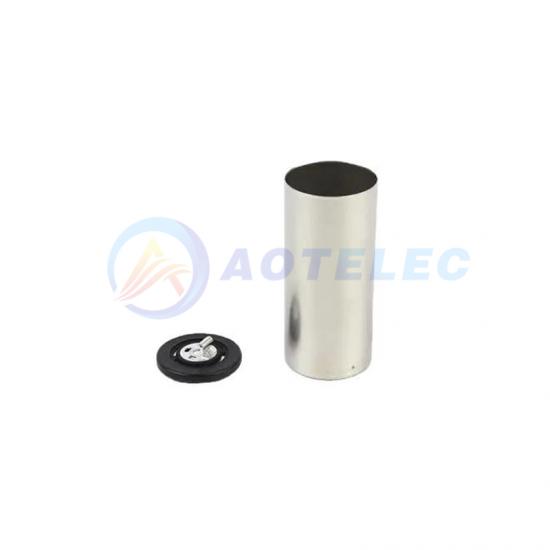

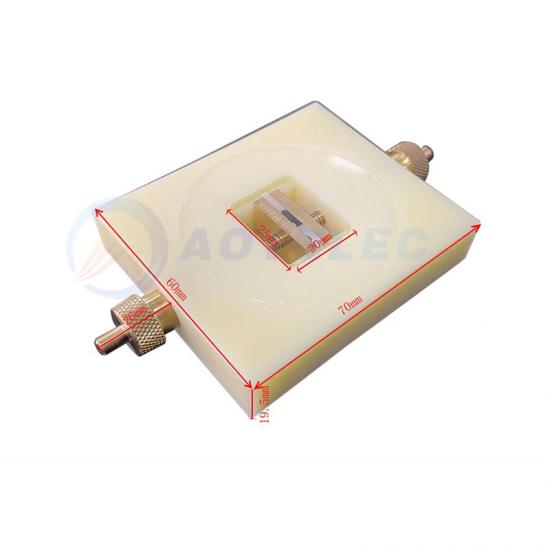

Inner cavity |

Dia.22 x 70mm |

Dia.30 x 150mm |

Dia.40 x 150mm |

Dia.50x 150mm |

|

Cavity withstand pressure |

≤300 MPa/12t |

≤300 MPa/22t |

≤300 MPa/39t |

≤300 MPa/60t |

|

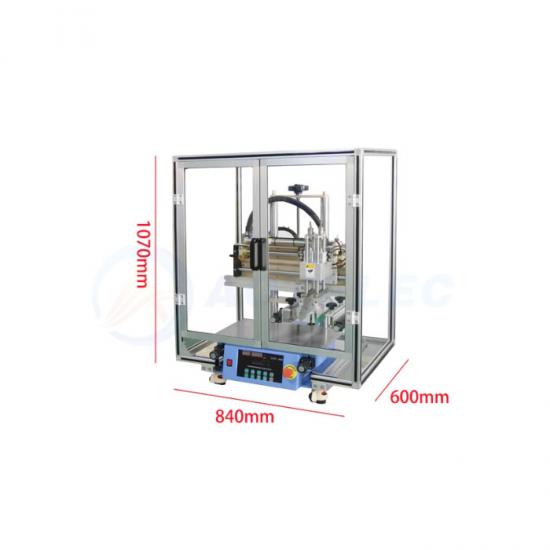

Dimension |

305x430x580mm |

305x430x600mm |

355x450x710mm |

405x470x720mm |

|

Net weight |

110Kg |

120Kg |

150Kg |

200Kg |

|

Configuration |

One hydraulic press and one set of isostatic chamber. Customized 500MPa static press or rubber mold according to requirements |

|||

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1:How long do you need to prepare my goods?

A: 3-5 days for battery materials. 5-25 days for equipment (based on different model and quantities).

Q2:Can we have our logo or company name to be printed on products or package?

A: Sure. your logo could be printed on your products by hot stamping, printing, embossing, UV coating, silk-screen printing or sticker. In order to explore the market better and provide more convenient services to global customers, we sincerely invite overseas agent to create bright future together.

Q3:How can I install and operate the machine by myself?

A: Our system R&D based on integrated development view. when you get the machine, just need to connect it with the electrical power, then machine can be working. because the English software were installed in this machine. what you need to do is only learning the software usage, and the complete English user manual will be coning to you with the machine.

Q4:How to get technical support after purchasing?

A: Our factory provide online technical support in English , you can easy catch us online by Skype, Wechat, and Email, if you need any remote assistant support, then we will support you though Team Viewer.

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported