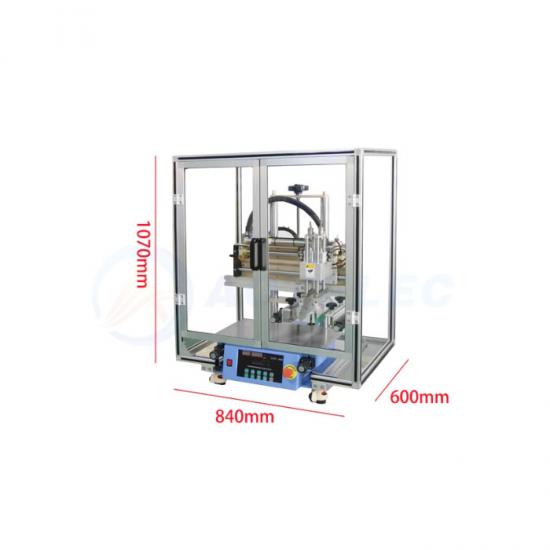

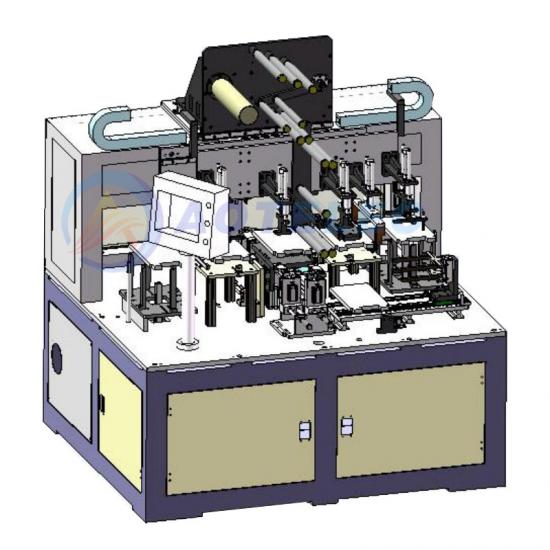

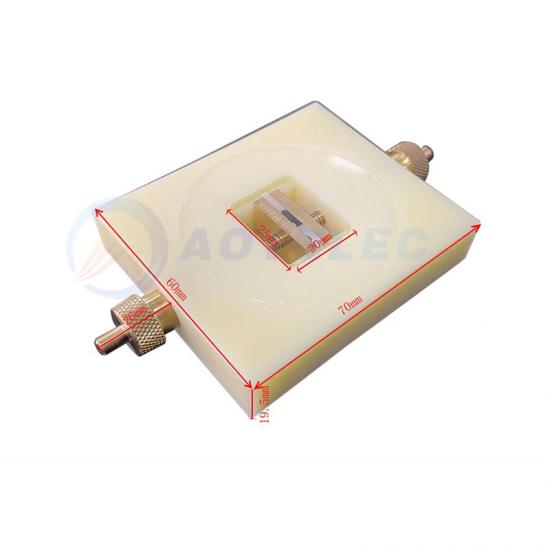

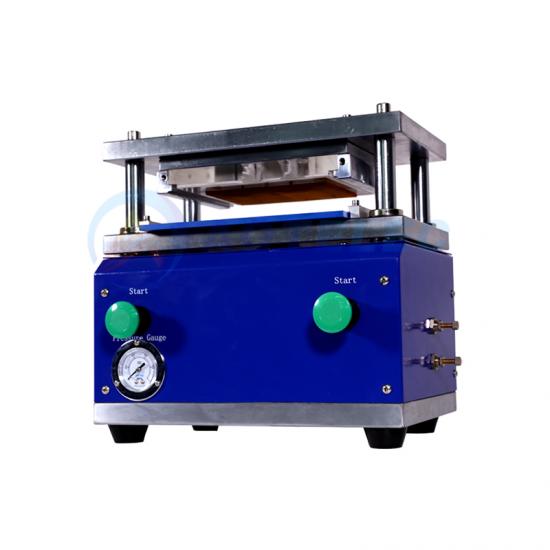

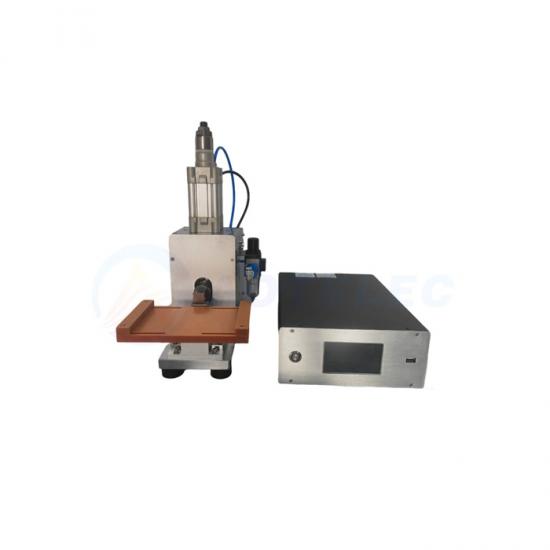

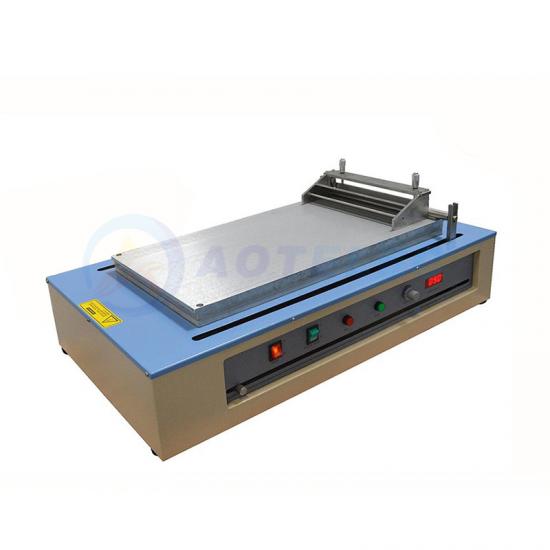

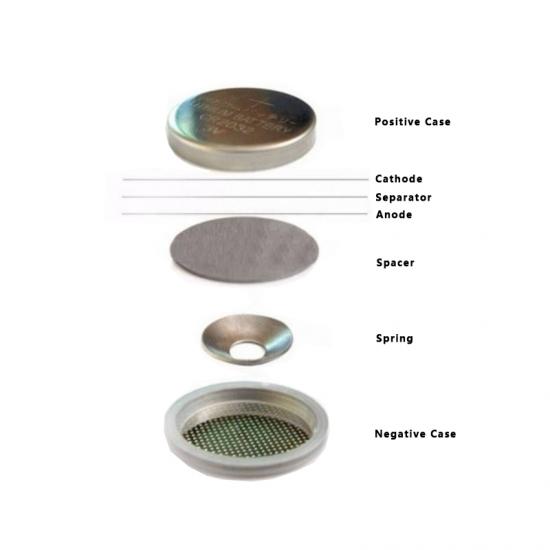

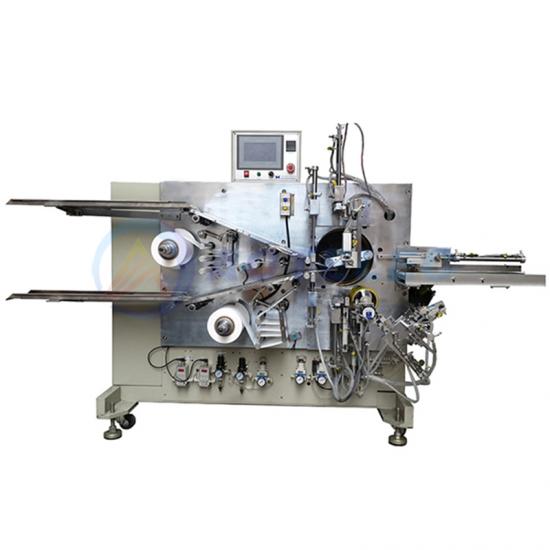

AOT-MSK-PSC-MM2020 is a precise sheet-to-sheet slot die coater with a 200 mm coating width and the super flat marble vacuum chunk is used for thin film coating with high uniformity. This coater is designed for ultrathin perovskite layer coating with diluted precursor solutions.

|

Product Model |

AOT-MSK-PSC-MM2020 |

|

Power |

AC220V±10%, 50/60Hz, 220W

|

|

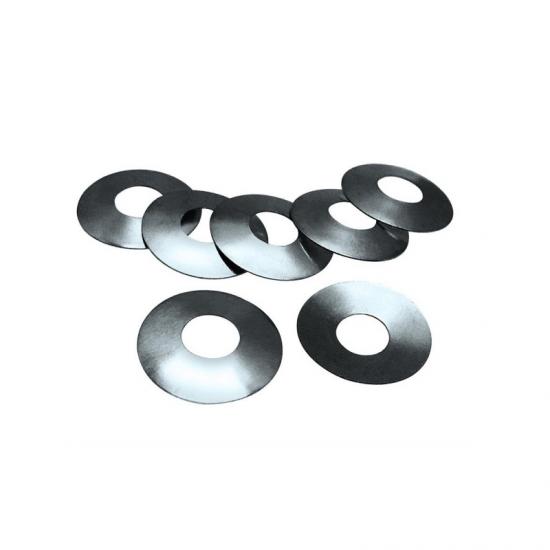

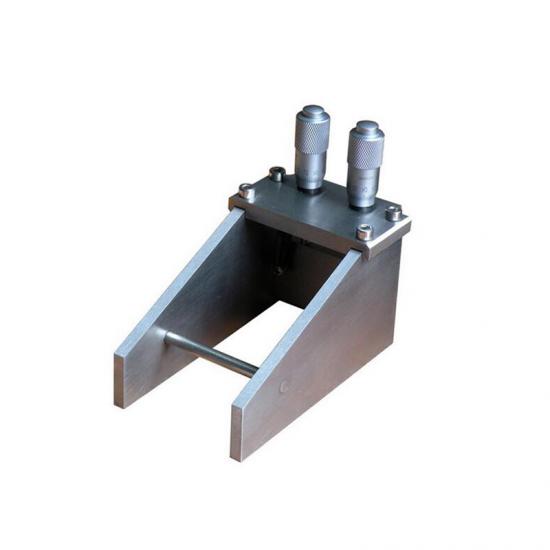

Slot Die Head |

200 mm width slot die head with 3 pcs shims with thickness 0.02, 0.04, 0.06 mm included (others thicknesses are available upon request) Different open-mouth width shims for various coating width are available upon request. Minimum coating thickness: 2 um (depending on slurry viscosity) Inside channel volume is 2 mL

|

|

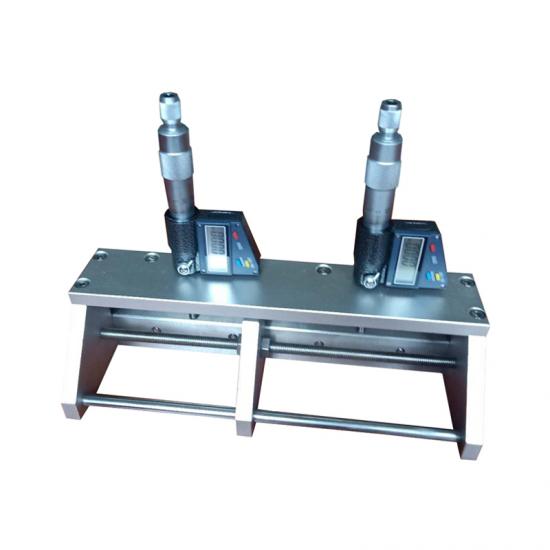

Gap Control |

0-6.8 mm with digital micrometer, accuracy is ±1 um

|

|

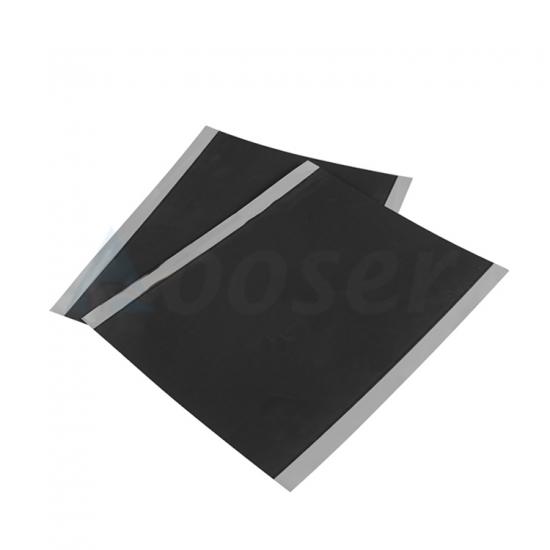

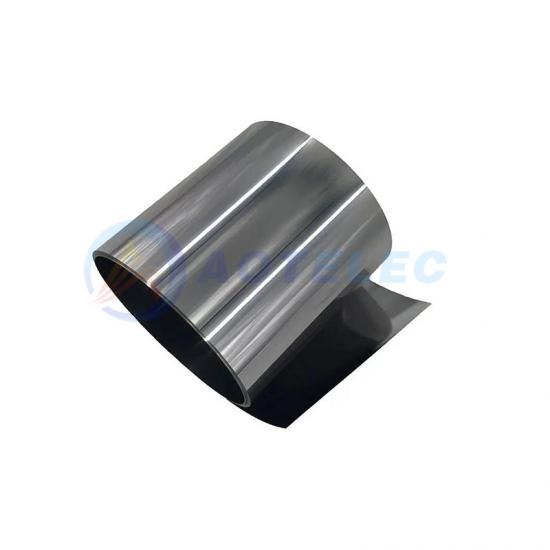

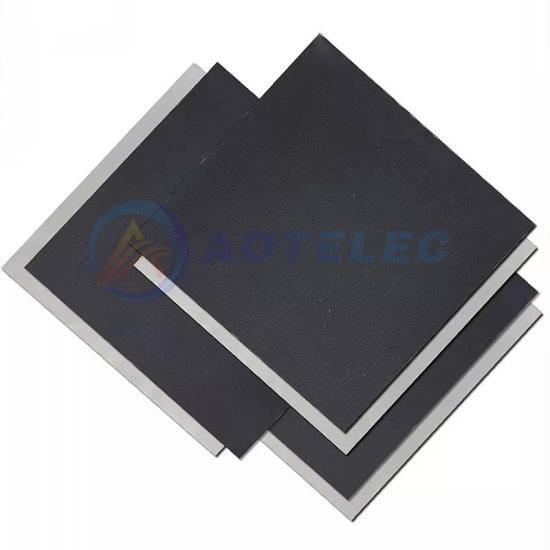

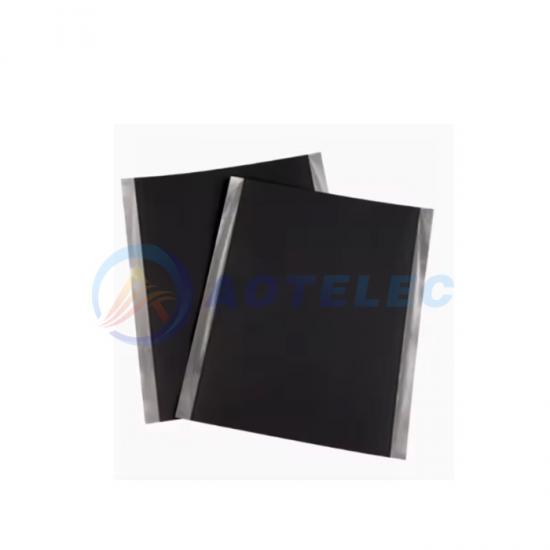

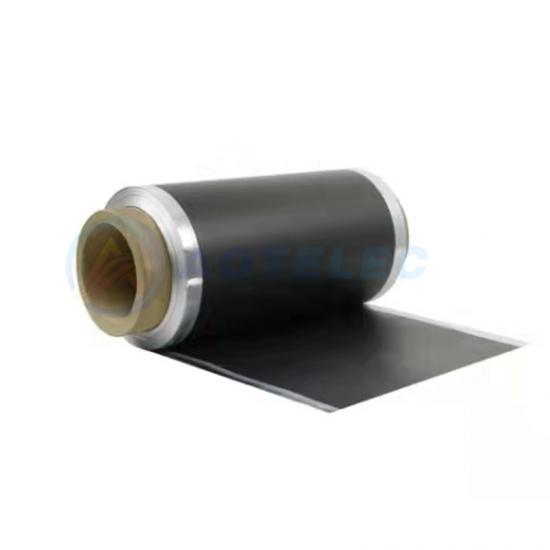

Substrate |

Rigid substrates, such ITO, FTO. Max. thickness is <3.2 mm Flexible substrate, such as ITO or FTO on PET

|

|

Travel Speed & Length Coating

|

Travel Speed: Max. 25 mm/s adjustable via touch screen control panel Maximum coating area: 200 mm W x 200 mm L 5 um-100 um (wet film, depends on material property) Slurry feeding speed: 5 mL/min Syringe volume: 10 mL Slurry viscosity: 1-1000 cps

|

|

Marble Vacuum Chuck |

Surface accuracy is ≤5um Small hole diameter: 3 mm, four holes Vacuum pump is externally connected

|

|

Control Panel |

4" color touchscreen panel to set coating speed, heating temperature, and syringe pump speed

|

|

Dimension |

W345mm×D514mm×H230mm

|

|

Weight |

31kg |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1:How long do you need to prepare my goods?

A: 3-5 days for battery materials. 5-25 days for equipment (based on different model and quantities).

Q2:Can we have our logo or company name to be printed on products or package?

A: Sure. your logo could be printed on your products by hot stamping, printing, embossing, UV coating, silk-screen printing or sticker. In order to explore the market better and provide more convenient services to global customers, we sincerely invite overseas agent to create bright future together.

Q3:How can I install and operate the machine by myself?

A: Our system R&D based on integrated development view. when you get the machine, just need to connect it with the electrical power, then machine can be working. because the English software were installed in this machine. what you need to do is only learning the software usage, and the complete English user manual will be coning to you with the machine.

Q4:How to get technical support after purchasing?

A: Our factory provide online technical support in English , you can easy catch us online by Skype, Wechat, and Email, if you need any remote assistant support, then we will support you though Team Viewer.

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported