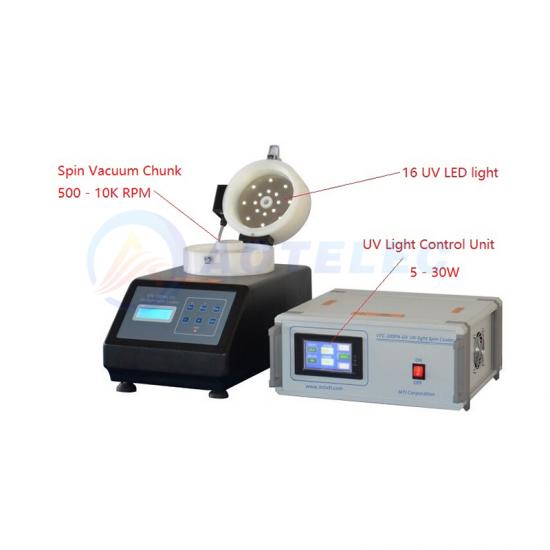

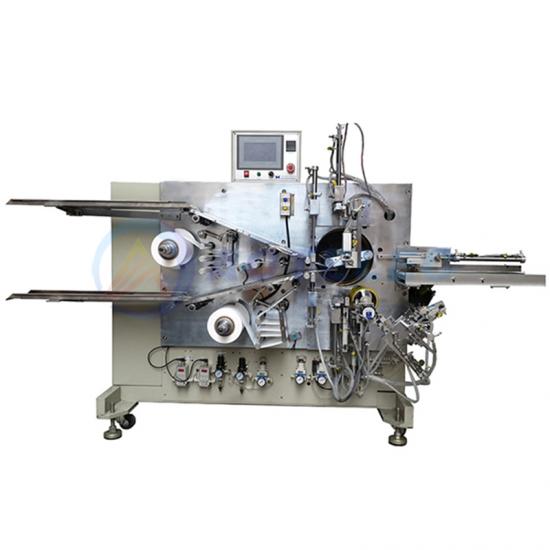

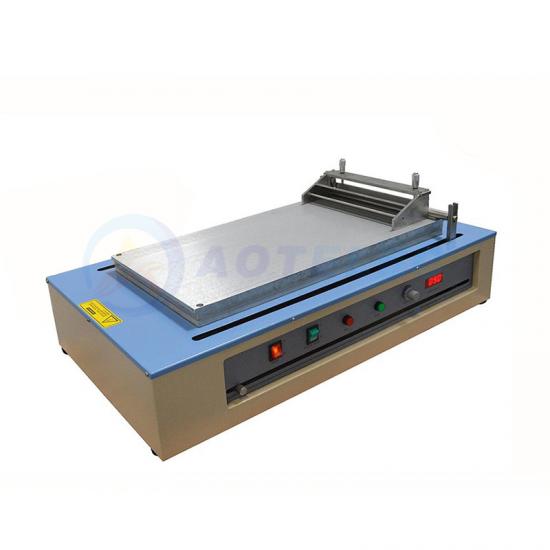

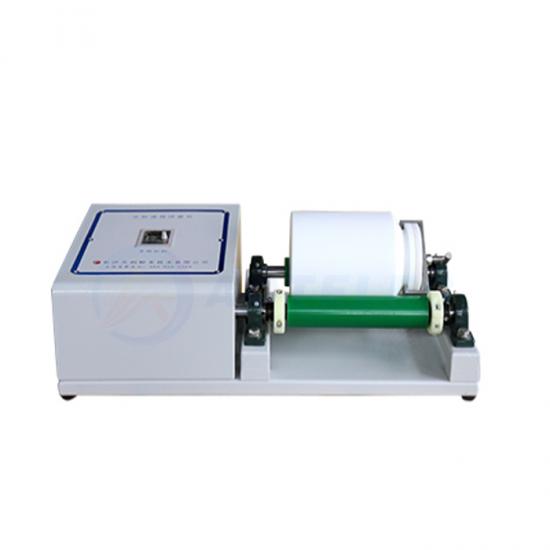

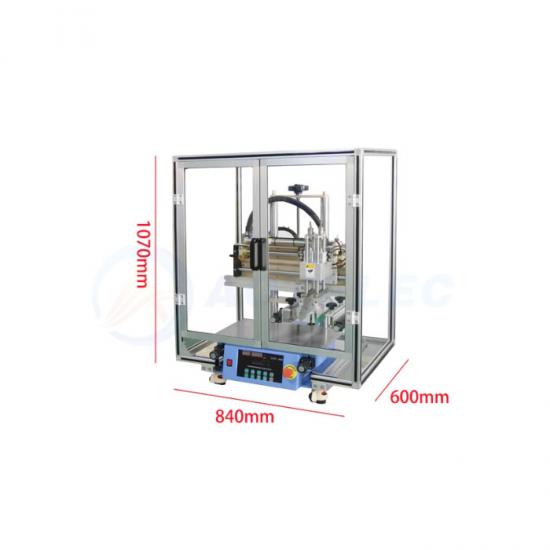

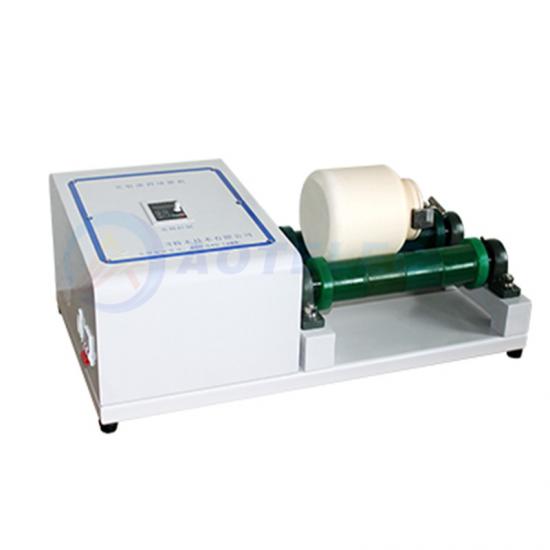

The vacuum spin coating machine is mainly used for forming films on the surface of liquids and materials.

Product features:

1. It can store the rotational coating process for 26 different samples. Each coating process can be set with 51 different speed states, ranging from 1 to 9999 seconds per step. (Most machines have 10 programs and 10 steps.)

2. The rotational speed ranges from 400 to 10,000 rpm. The preset value is 5,000 rpm, and the actual value fluctuates between 4,998 and 5,002. (This parameter determines the flatness and uniformity of the film, as well as its repeatability and consistency.)

3. It can control acceleration.

4. The end jump coefficient is ±2% for 1 millimeter.

(This parameter determines the flatness and uniformity of the film, as well as its repeatability and consistency. This is equivalent to half the cross-section of a hair.)

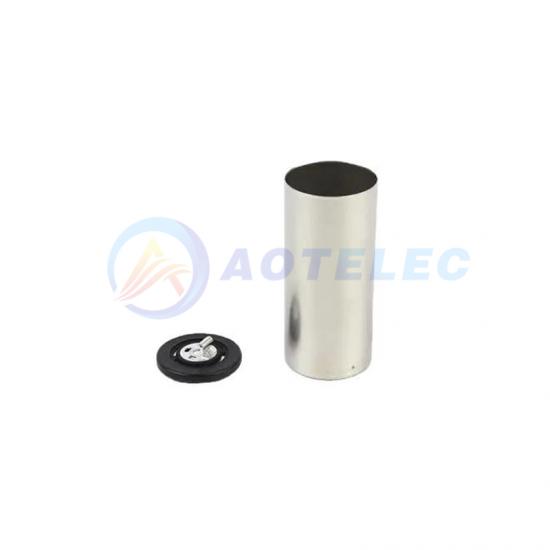

5. The suction cup has diameters of 8/10/16/20/25/33/50/62/75 mm, and it is made of polytetrafluoroethylene. 9 of them are selected from 10.

(The material is good. Most in China are made of metal, while in the rest of the world, they are made of polytetrafluoroethylene.)

6. The motor has a power of 150W, which can support the rotation of a substrate weighing about 300g at 2,000 rpm.

7. The anti-flying sheet system prevents the machine from starting when the vacuum pressure is insufficient.

8. The LCD display can show real-time information:

a. The Nth coating process

b. The current working section

c. The vacuum suction sheet status.

d. The set time and real-time running time.

e. The set speed and real-time speed status.

|

Suitable substrate range |

5 - 150mm wafer Rotary vacuum chuck diameter: 4 inches (102mm) Optional configuration: Wafer diameter 10 - 150mm |

|

Speed |

300 - 10,000 revolutions per minute, speed stability: ±0.1%, variable frequency servo motor, motor power 150W |

|

Time |

1 to 9,999 seconds |

|

Acceleration |

Can be set up |

|

Program |

26 programs, each consisting of 51 steps, with each step ranging from 0 to 9999 seconds. (Most machines on the market have 10 programs and 10 steps.) |

|

Vacuum |

The gluing machine and spin coating instrument are equipped with a vacuum sensor. During the coating process, the computer continuously monitors the system vacuum level to prevent film shedding. Fly-off prevention system: Under a safe vacuum level, the motor starts and operates. To ensure reliable suction and prevent film shedding, the machine will not start when the vacuum pressure is insufficient. Uses a 60L oil-free vacuum pump. Features: No need for any lubricating oil, can be used continuously for a long time, and uses a single power supply. Technical Specifications Absolute vacuum: -0.098 MPa Vacuum pumping efficiency: 60 (L/min) Power: 0.45 (kW) Voltage: 220V/50Hz (Hz/v) |

|

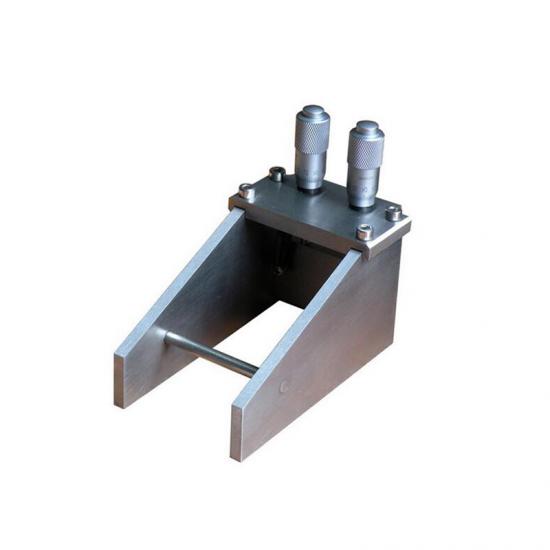

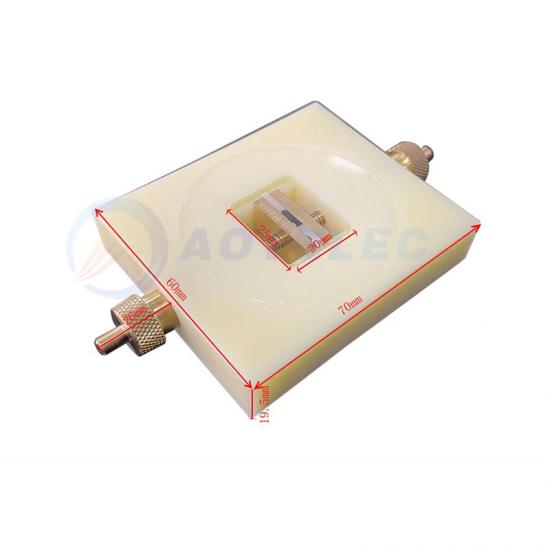

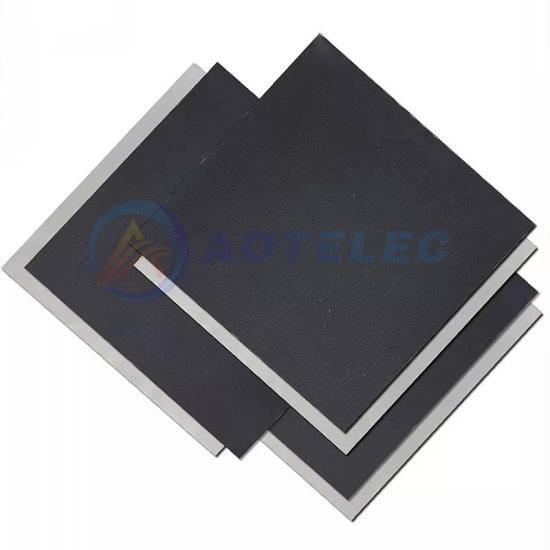

Working chamber |

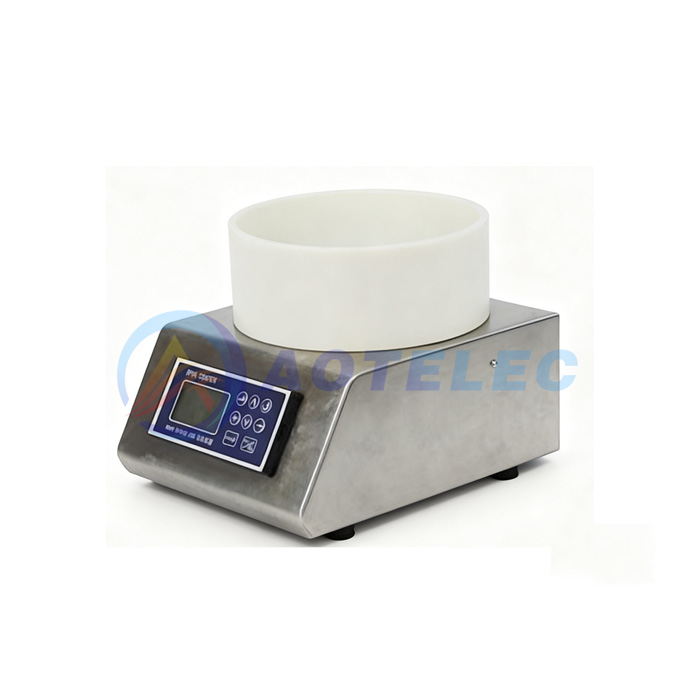

Working chamber: Made of NPP material. It can be easily disassembled for cleaning and can be wiped with acetone. |

|

All models of suction cups can be used |

Yes |

|

The use of thin-film seamless suction cups is possible. |

Yes |

|

Easier to be placed in the glove box |

Yes |

|

Size |

260mm wide x 350mm deep x 260mm high |

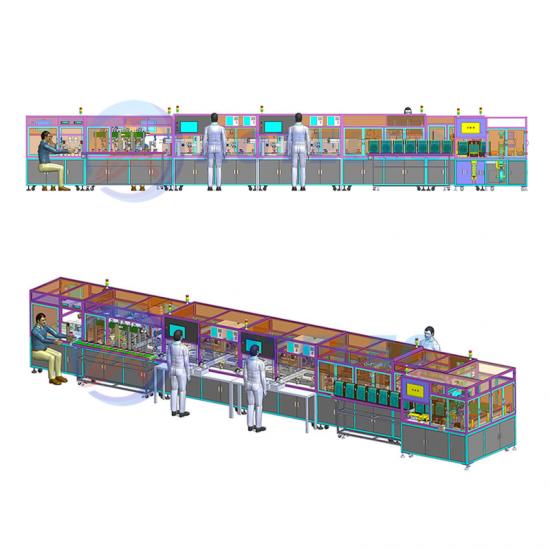

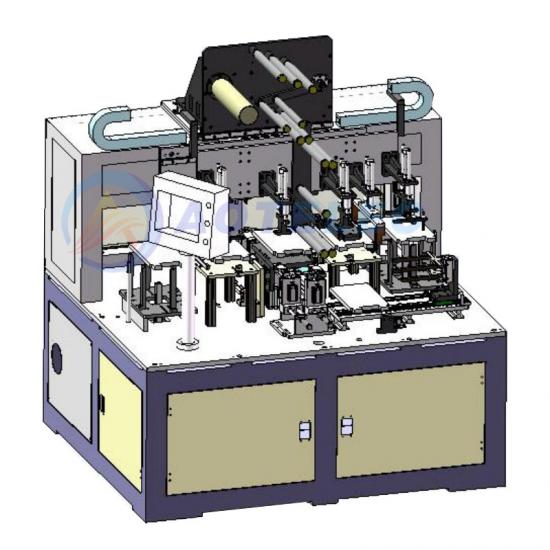

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1:How long do you need to prepare my goods?

A: 3-5 days for battery materials. 5-25 days for equipment (based on different model and quantities).

Q2:Can we have our logo or company name to be printed on products or package?

A: Sure. your logo could be printed on your products by hot stamping, printing, embossing, UV coating, silk-screen printing or sticker. In order to explore the market better and provide more convenient services to global customers, we sincerely invite overseas agent to create bright future together.

Q3:How can I install and operate the machine by myself?

A: Our system R&D based on integrated development view. when you get the machine, just need to connect it with the electrical power, then machine can be working. because the English software were installed in this machine. what you need to do is only learning the software usage, and the complete English user manual will be coning to you with the machine.

Q4:How to get technical support after purchasing?

A: Our factory provide online technical support in English , you can easy catch us online by Skype, Wechat, and Email, if you need any remote assistant support, then we will support you though Team Viewer.

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported