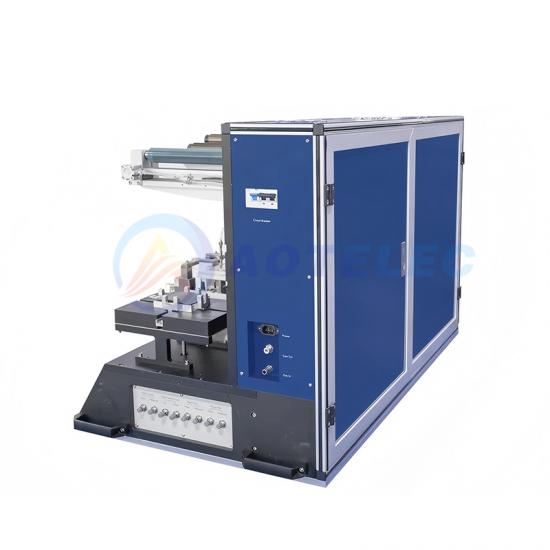

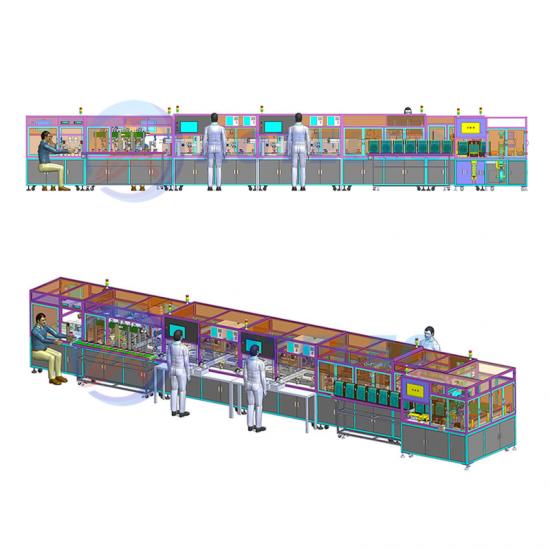

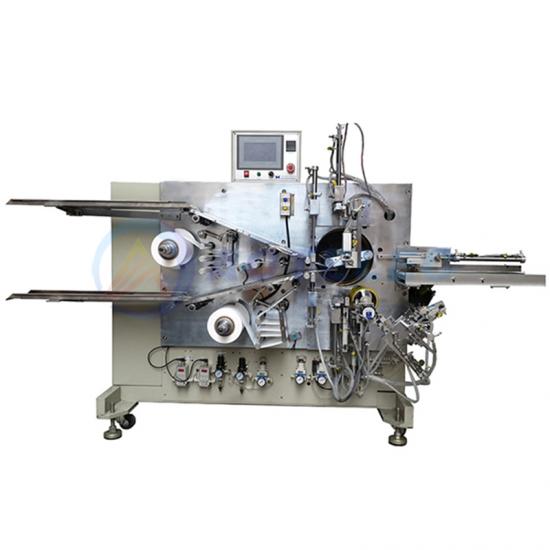

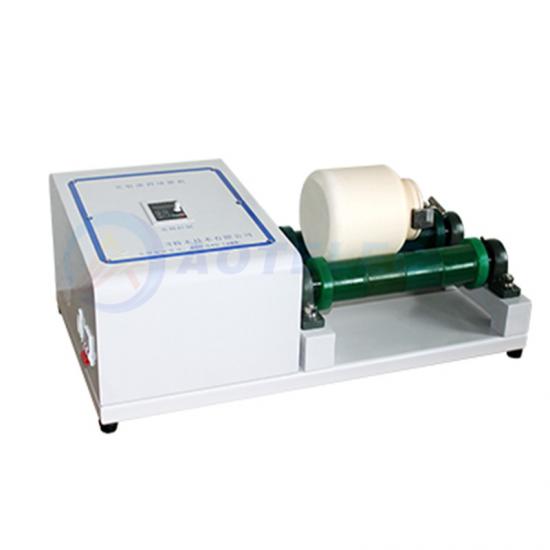

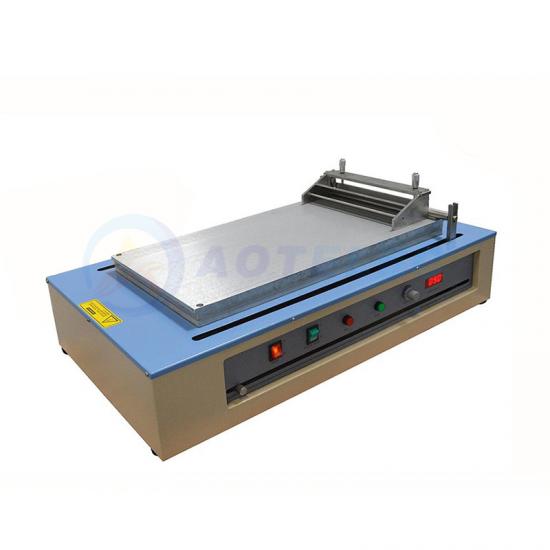

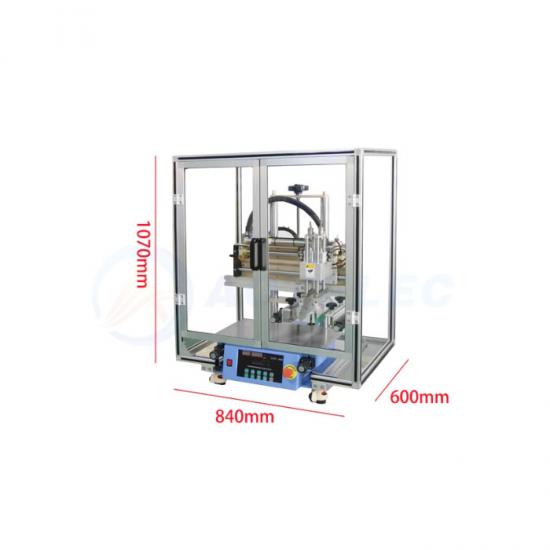

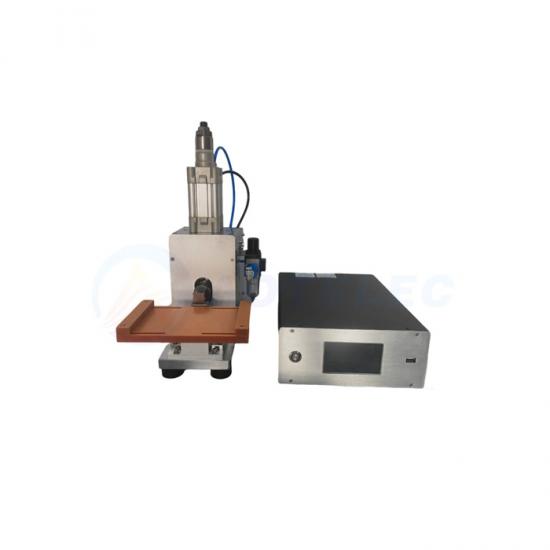

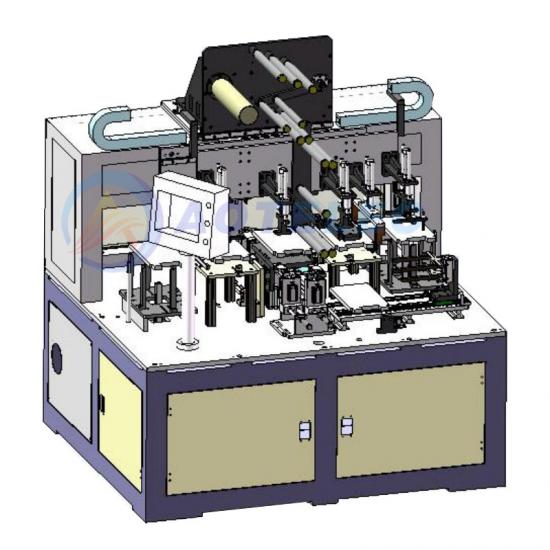

AOT- MSK-111A-PEM automatic stacking machine is a multifunctional stacking device that can be applied to ordinary lithium-ion batteries and metal lithium-ion batteries with Z-shaped separators, as well as solid-state batteries with sheet structure separators. The desktop structure design of this device can be placed in a glove box for use. It is an automated equipment suitable for laboratory or small-scale production.

Advanced Features:

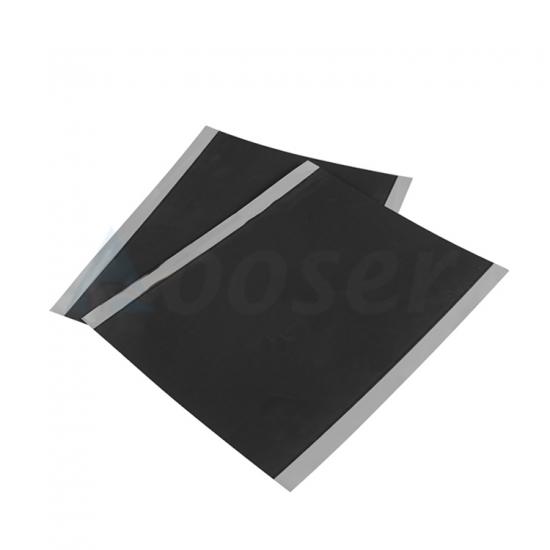

1. One machine with three uses, capable of stacking ordinary lithium-ion batteries, metal lithium-ion batteries, and solid-state batteries, and the three functional programs can be freely switched;

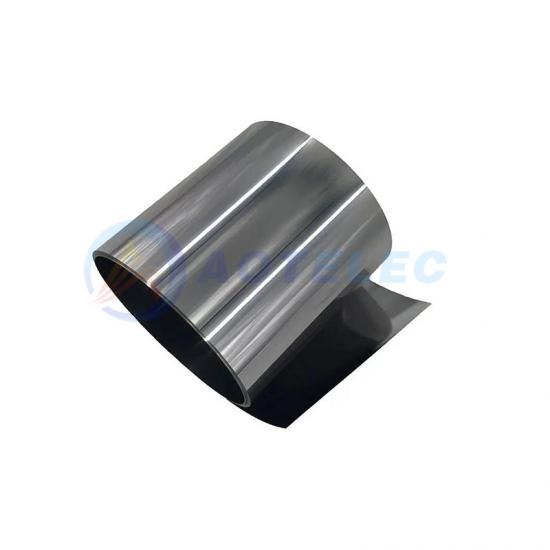

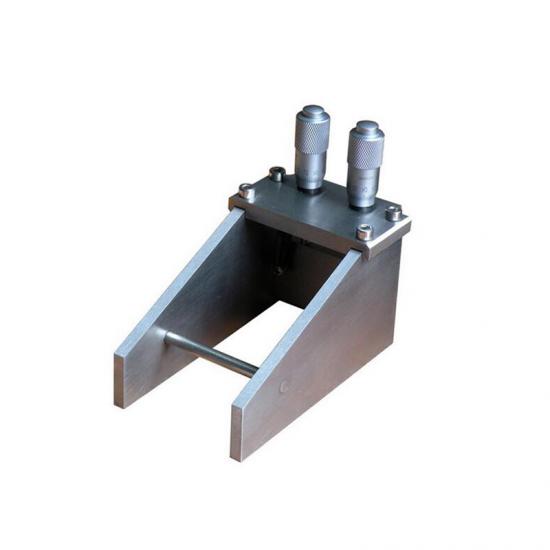

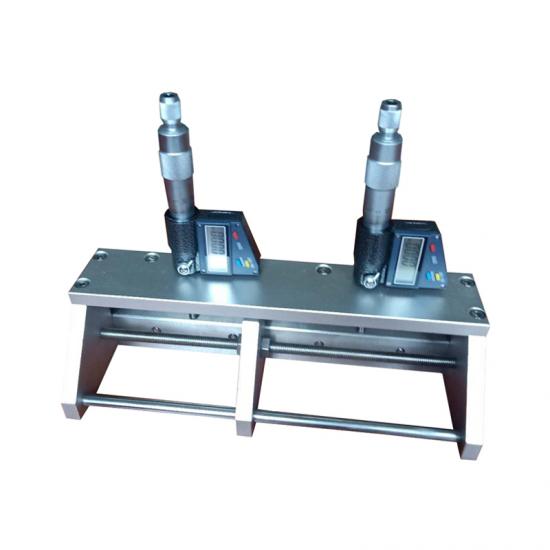

2. The thinnest lithium metal that can be stacked up to 30 μ m is non adhesive and has no obvious indentation;

3. After completing the stacking process, manually remove the battery cells using a fixture and directly apply adhesive to the fixture;

4. Equipped with a built-in vacuum pump as standard, but can also choose to use an external one;

5. The number of laminations can be freely set;

6. Adopting compatibility design, battery size changes can be achieved through customized molds and adjusting pressure claws, with a wide range of adjustments;

7. PLC control, HMI operation, easy to use and maintain;

8. Can be used inside the glove box (compatible with argon and nitrogen)

Technical Parameter:

|

Product Name |

Automatic Pouch Cell Stacking Machine |

|

Power Supply |

Single-phase AC220V ± 10% (customizable AC110V), frequency 50/60Hz, power 400W |

|

Gas Source |

0.5-0.8MPa compressed air |

|

Vacuum Source |

Vacuum degree better than -60Kpa (standard built-in vacuum pump, external option is also available) |

|

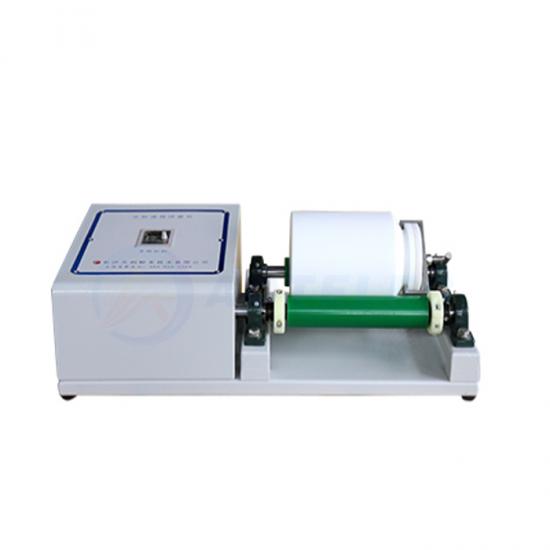

Stacking Method |

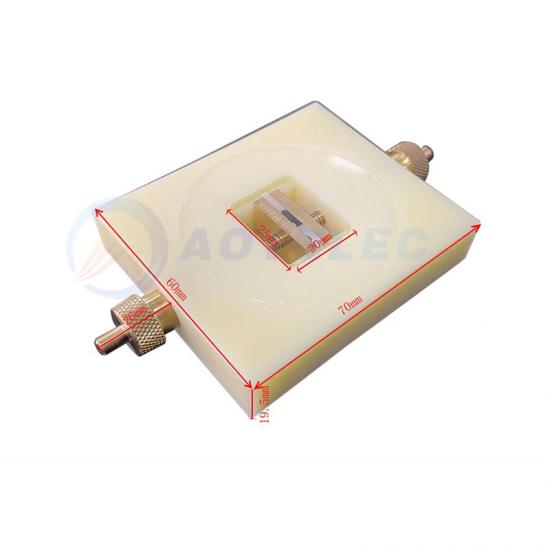

Z-shaped stacking, solid-state stacking (the separator is a sheet, and the separator, negative electrode sheet, separator, positive electrode sheet, etc. are automatically stacked in sequence) |

|

Operation Mode |

Manual feeding, automatic stacking, automatic diaphragm cutting |

|

Stacking Cycle |

4-6S/piece for electrode stacking, 6-8S/piece for lithium metal stacking (excluding the preparation time for stacking each battery cell) |

|

Electrode Width |

50-150mm (tab on this side) |

|

Electrode Length |

100-200mm (excluding tab size) |

|

Stacking Thickness |

Max.20mm |

|

Current Corrector Tab Length |

Max.15mm |

|

Equipment Size |

L1220 * W610 * H720mm |

|

Weight |

180KG |

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported