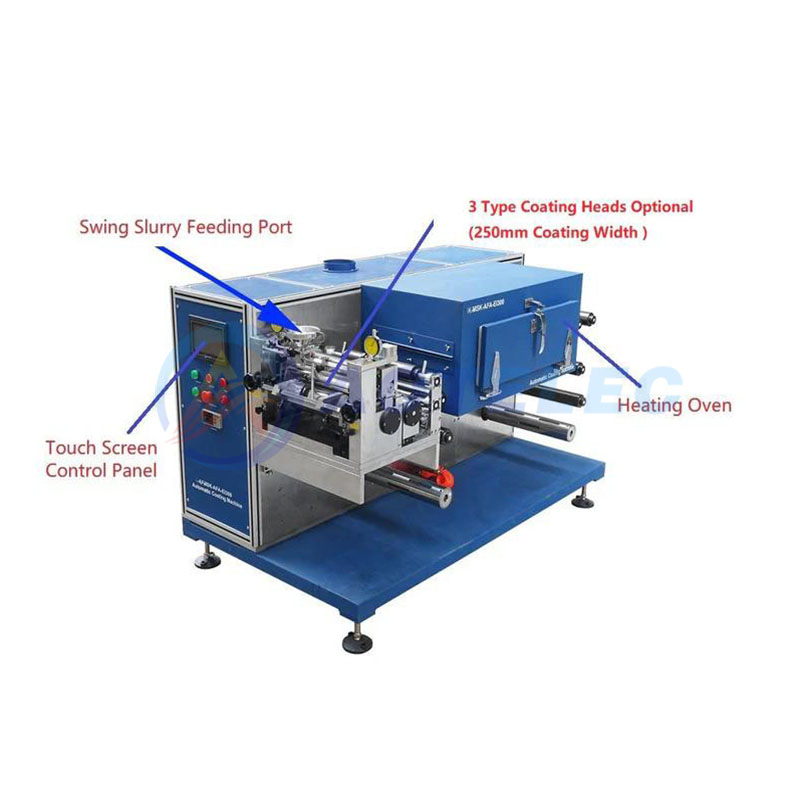

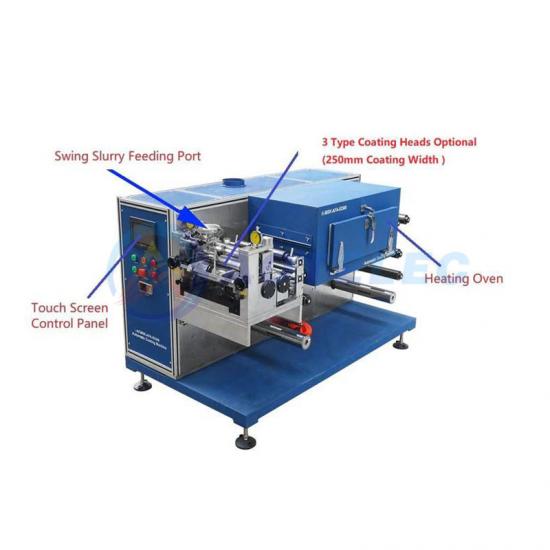

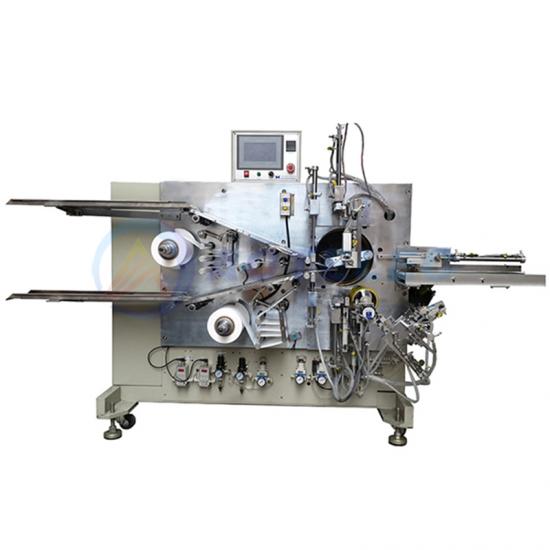

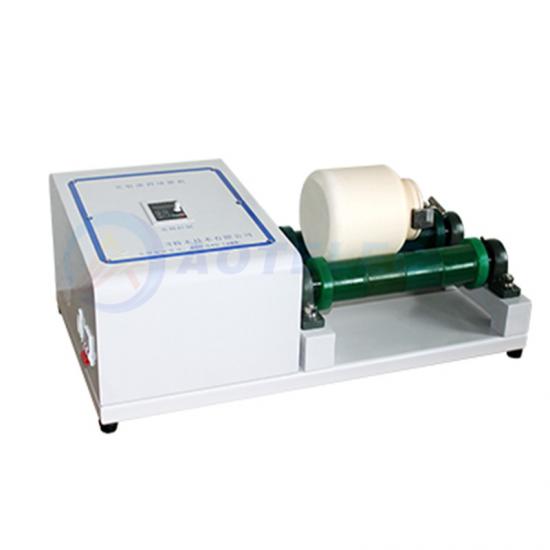

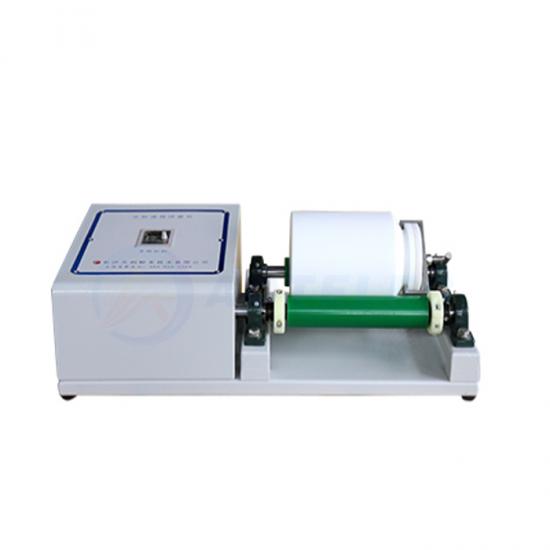

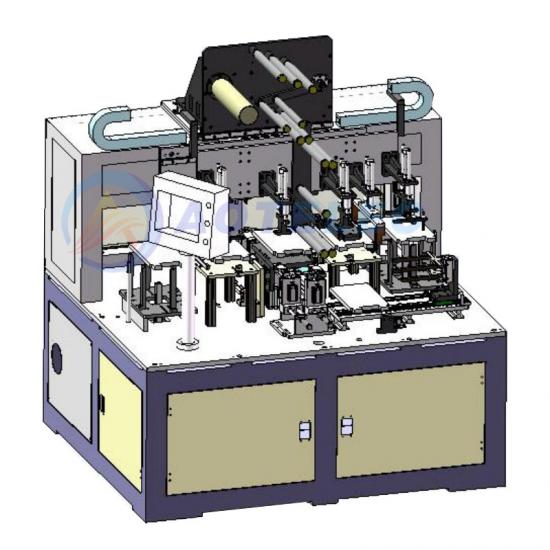

AOT-AFA-EI300 scraper three roll transfer coating machine, roll to roll method, continuous and intermittent coating, width 300mm, coating width 50-260mm, coating surface density accuracy ± 1.5%, 150 ℃ hot air oven, suitable for 8-30 μ m thick metal substrates, including slurry stirring, winding correction function, optional NMP treatment and plasma cleaning.

Functional Features

Transfer coating:

1. Wide coating window, suitable for various coating scenarios, especially suitable for the early research and development stage;

2. Can achieve continuous and intermittent coating;

3. Measurement with comma scraper, manual adjustment of scraper height, high coating accuracy;

4. Manually adjust the coating width;

5. The material box contains mixing function.

6.Substrate tension control, stable tape running, equipped with winding correction device;

7.Hot air oven, double-sided blowing on both sides, with high-quality drying effect;

8.PLC control, HMI operation, convenient and easy to use;

9.Optional additive treatment device.

|

Product Name |

Roll to Roll Coating Machine |

|

Power Supply |

Single phase AC220V ± 10%, frequency 50Hz, power 5KW |

|

Gas Source |

0.5-0.8MPa compressed air |

|

Coating Type |

continuous coating, Intermittent coating |

|

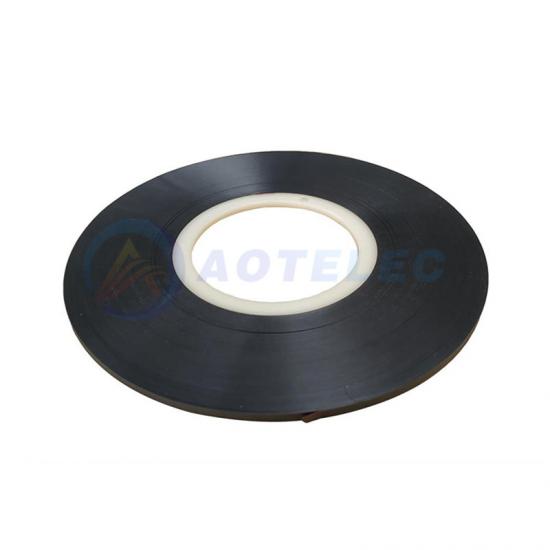

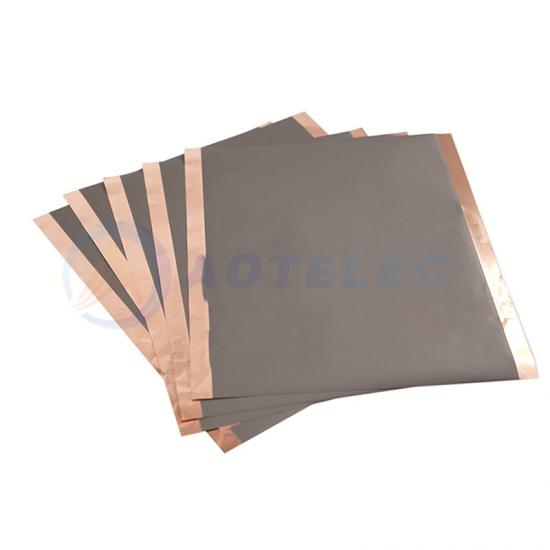

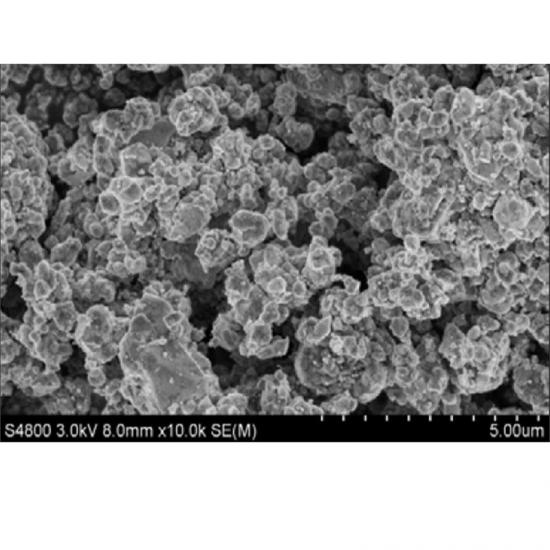

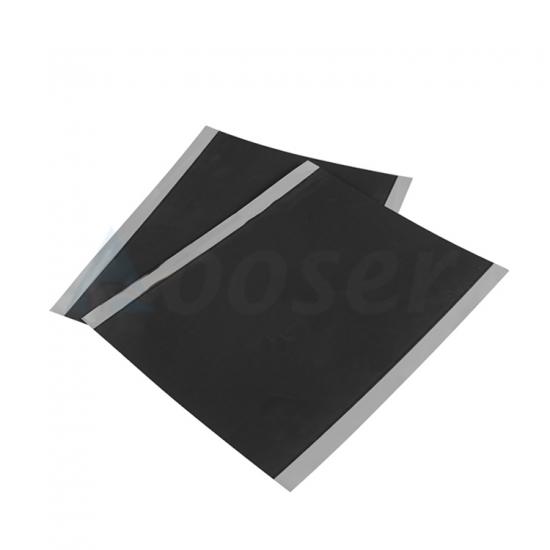

Applicable Systems |

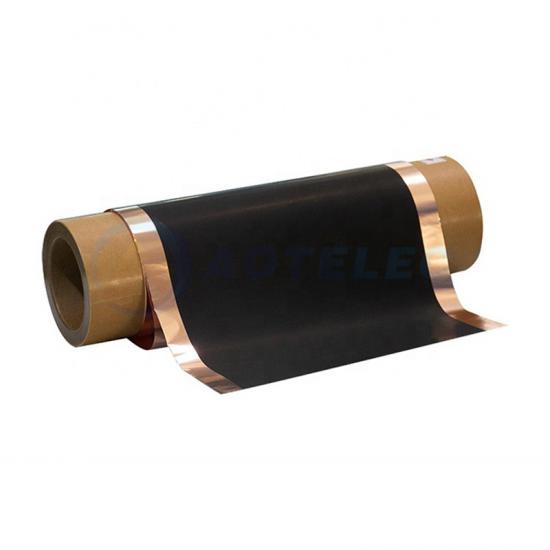

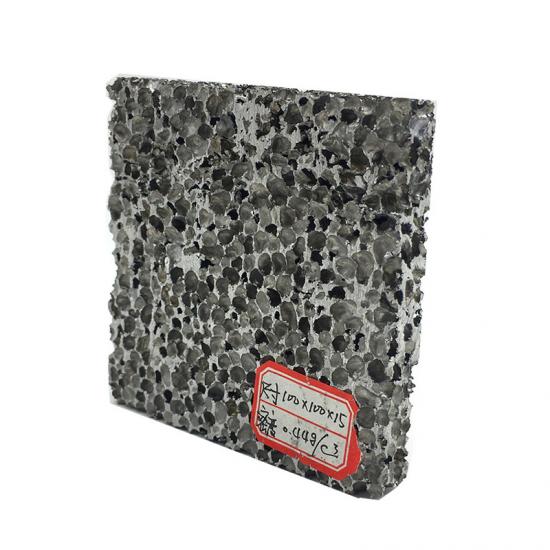

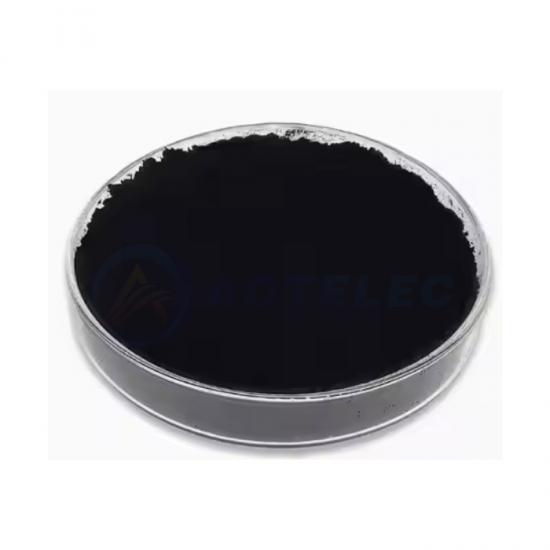

positive electrode oil-based slurry (lithium cobalt oxide, lithium iron phosphate, lithium manganese oxide, ternary), negative electrode water-based slurry (graphite, silicon-based negative electrode), supercapacitor slurry |

|

Applicable Systems |

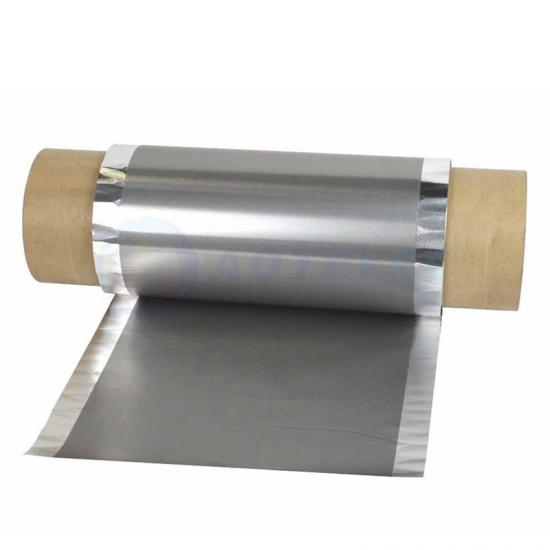

Guide roller width 300mm |

|

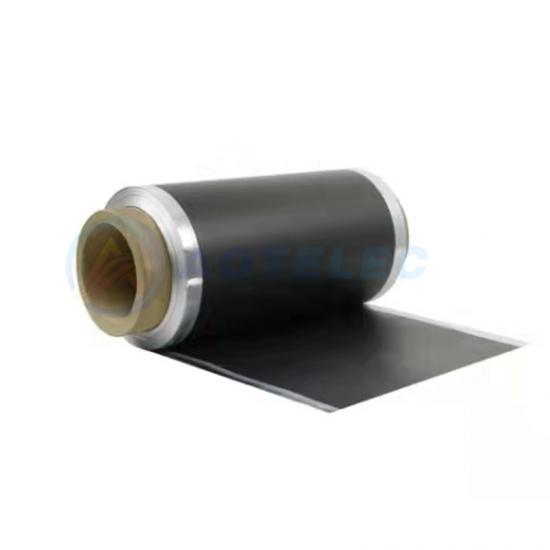

Substrate Width |

Max.280mm |

|

Coating Width |

50-250mm, adjustable through baffle |

|

Mechanical Speed |

0.01-0.7m/min |

|

Coating speed |

Max.0.3m/min reference graphite negative electrode coating speed, viscosity 2000 mPa. s, solid content 45%, coating dry thickness 90um) |

|

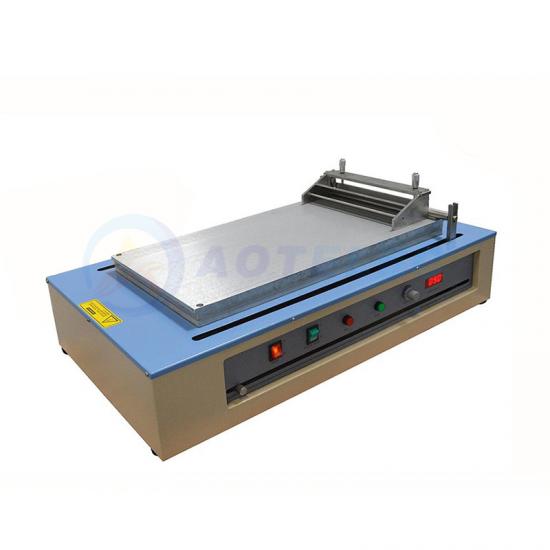

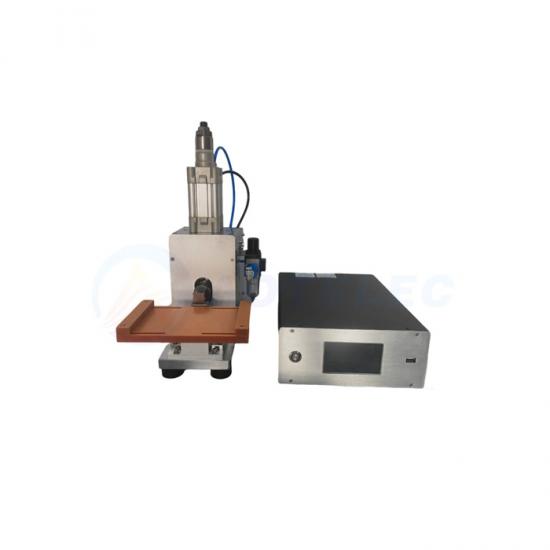

Coated steel Rod |

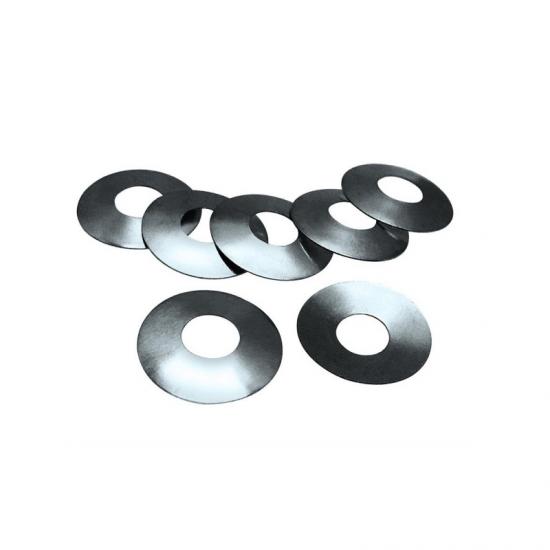

Ф100mm, Surface chrome plating, circular runout ≤ 3 μ m (measured by mechanical micrometer) |

|

Coating Roller |

Ф100mm, Surface EPDM rubber |

|

Rubber Roller Movement |

Cylinder driven |

|

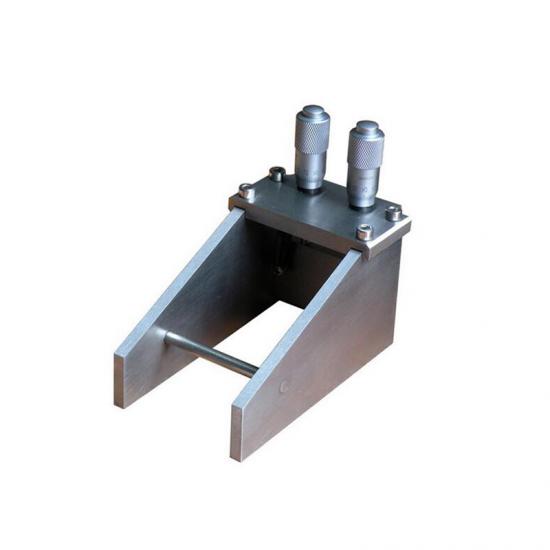

Coating Scraper |

Ф100mm, Surface chrome plated, single blade |

|

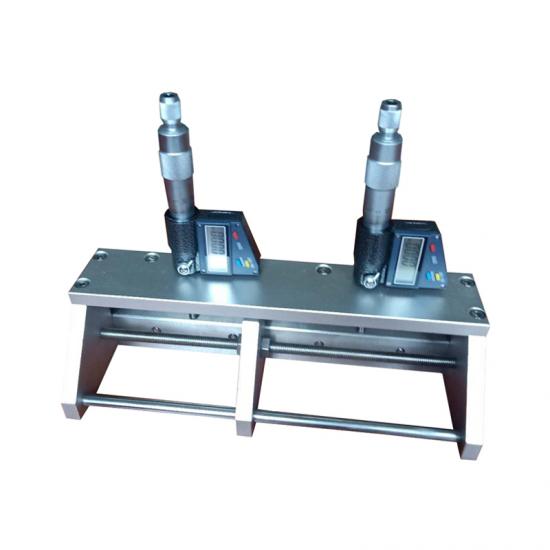

Scraper Adjustment |

Manual adjustment, micrometer display accuracy of 1 μ m |

|

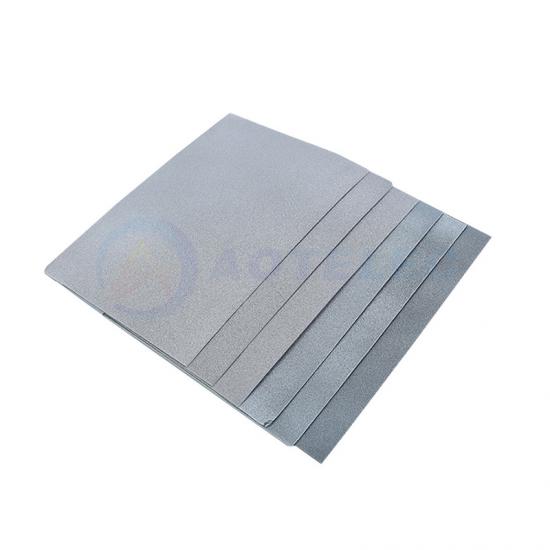

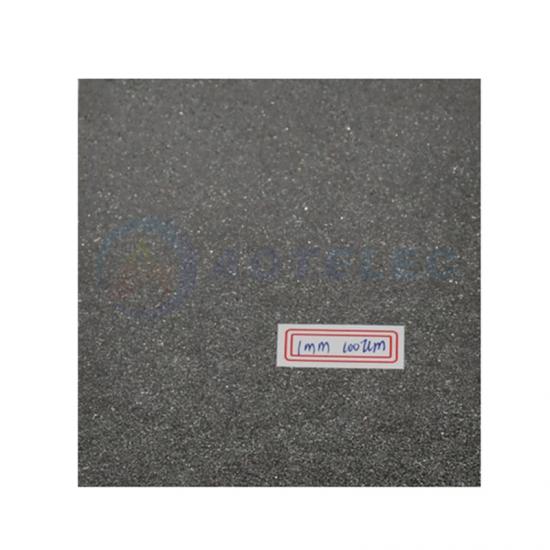

Coating Thickness |

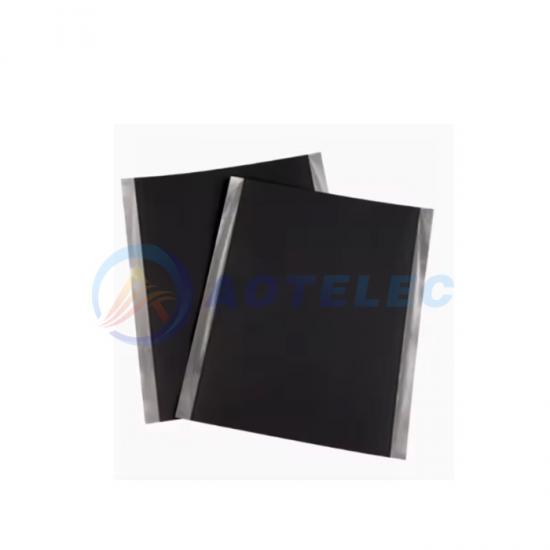

Continuous coating single-sided dry thickness: 30-150 μ m (depending on the slurry, refer to material requirements) |

|

Intermittent Coating single-sided Dry Thickness |

30-100 μ m (depending on the slurry, refer to material requirements) |

|

Accuracy |

≤ ± 3 μ m (reference, excluding edge abnormal areas, sampling and measurement standards refer to product evaluation) |

|

Align Both Sides |

± 0.5mm (length direction) |

|

Box Capacity |

About 0.7L (coating width 160mm) |

|

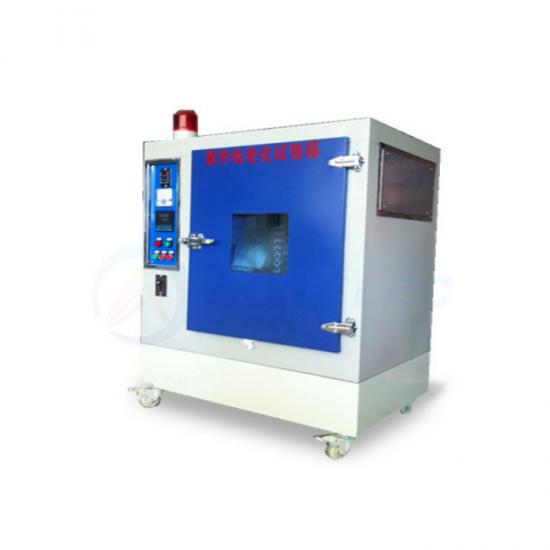

Drying Unit |

Single section length 0.8m, total 1 section (standard with hot air drying) |

|

Drying Temperature |

Max 150 ℃, uniformity ± 5 ℃ (working position, except for the beginning and end), adjustable |

|

Air Intake |

Centrifugal fan, air volume 198 m ^ 3 ⁄ h, power 50W |

|

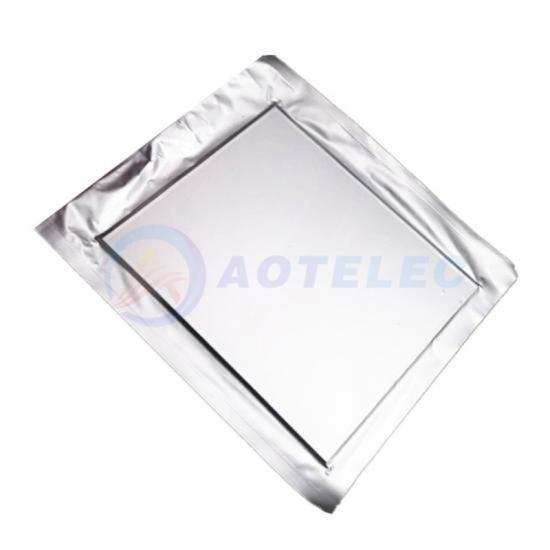

Exhaust Air |

Centrifugal fan, air volume 570 m ^ 3 ⁄ h, power 200W, interface: 5-inch aluminum foil duct |

|

Heating Box |

U-shaped heating tube, total 4KW |

|

Tension Control |

Max.60N |

|

Roll Diameter |

Max.Ф250mm |

|

Retractable Core |

3-inch expansion shaft |

|

Operation Direction |

Along the direction of foil transfer, the right side is the operating side |

|

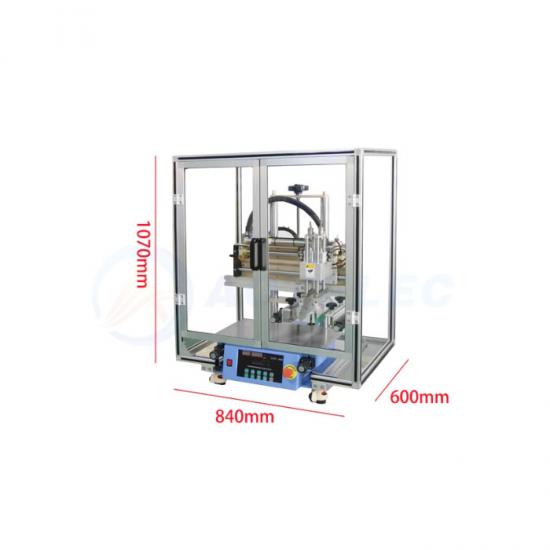

Equipment Dimensions |

L1650 * W950 * H1050mm |

|

Weight |

980kg |

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported