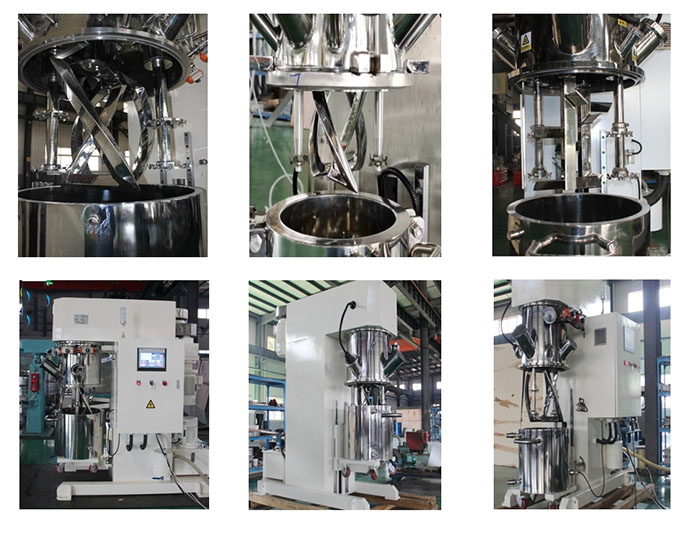

AOT-PM100L dual planet mixer is widely used for dispersing and mixing medium to high viscosity liquids, such as adhesives, sealants, silicone rubber, glass adhesive, solder paste, battery paste, electronic paste, lithium battery paste, polyurethane, coatings, pigments, dyes, synthetic resin rubber, etc.

|

Items |

30L |

60L |

100L |

200L |

|

Tank working Capacity/L |

30L |

60L |

100L |

200L |

|

Tank Design Size/L |

44L |

88L |

149L |

287L |

|

Tank Size/mm |

400*350 |

500*450 |

650*450 |

750*650 |

|

Revolution Motor/Kw |

3 |

7.5 |

11 |

22 |

|

Revolution Speed/rpm |

0-43 |

0-36 |

0-30 |

0-28 |

|

Mix Speed/rpm |

0-84 |

0-53 |

0-46 |

0-39 |

|

Disperse Motom/Kw |

5.5 |

11 |

15 |

30 |

|

Disperse Speed/rpm |

0-5500 |

0-4500 |

0-3700 |

0-2800 |

|

Disperse plate linear Velocity(m/s) |

0-23 |

|||

|

Suttle/Kg |

980 |

1700 |

2700 |

4200 |

|

Measurement/mm (L*W*H) |

1700*950*1900 |

1950*1200*2150 |

2300*1300*2400 |

2500*1400*3000 |

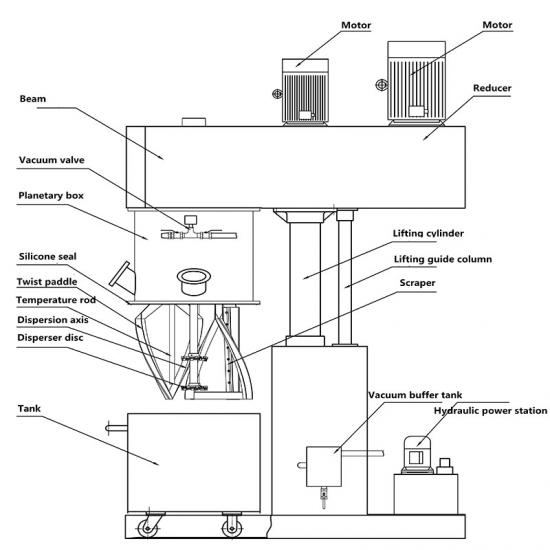

Main features:

1.High line speed

The line speed can reach to 25m/s, shorten the dispersing time (Each 5m/s increasing of line speed, the mixing time will reduce 20-30 minutes); The particle size of battery slurry is small and high uniformity, solve the problem of polymerization.

2. It adopts SKF Sweden import angular contact ball bearing

The vertical and horizontal loading is bigger than the deep groove ball bearing, The carry capacity is much higher, and bear higher rotating speed, large increase the mixing speed and using life

3.The gap between tank and paddles paddles to paddles (2-7mm),paddles to tank wall (2-7mm),paddles to tank bottom (2-6mm) , the gap is small, scraper design under the mixing paddles, High roundness inner the tank, The deviation is less than 0.2mm;

4.Large torsion output precision casting mixing paddles SS316 stainless steel (adopts special steel for machines bigger than 650L, The material can restore itself if there is micro deformation, The mixing paddles won’t deform under long time big torque running), The torque output is Simulation calculated by computer, High strength, suitable for high viscosity, high solid content Positive and negative pole slurry of Lithium battery (Lithium iron phosphate, ternary, ternary high nickel, Potassium manganate, Lithium Cobaltate etc) suitable for different process technology (dry mix, wet mix).

IPv6 network supported

IPv6 network supported