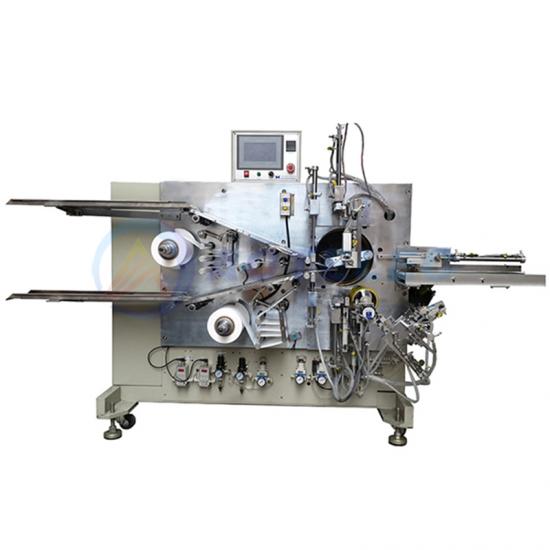

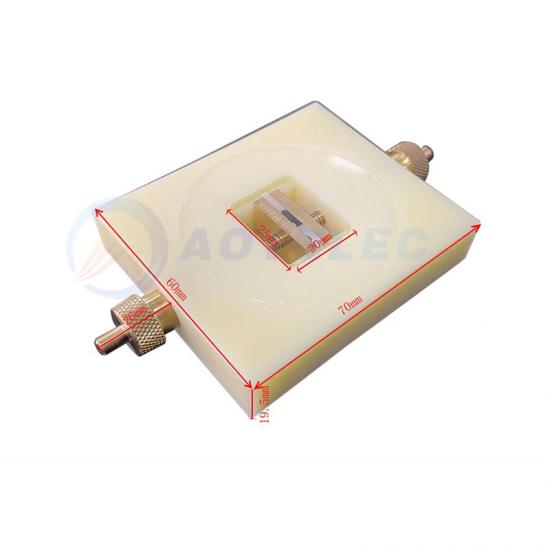

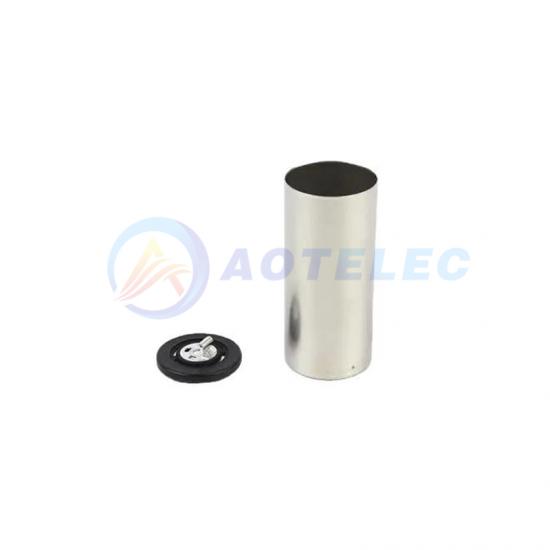

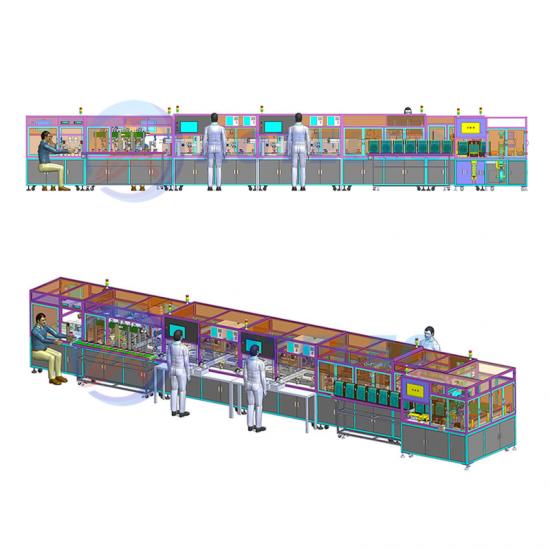

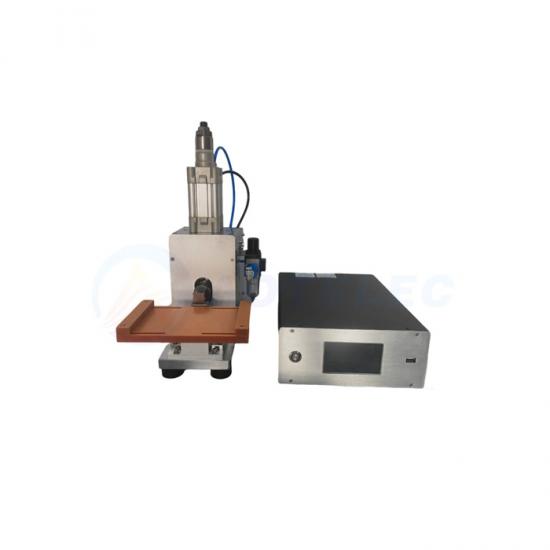

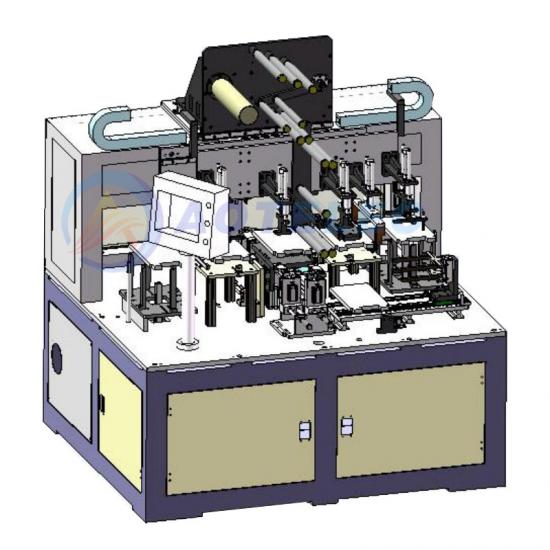

Lithium Battery Charging And Discharging Cycle Tester

This battery tester is mainly used for charging and discharging cycle test of lithium battery. The test items mainly include battery charging protection voltage, discharge protection voltage, capacity, etc. The equipment has four test steps①Charge, ②Discharge, ③Idle ④ Cycle. Test the battery by editing the corresponding steps and the set process.

Features:

1. The energy flows in two directions, and the discharge energy is fed back to the power grid efficiency ≥93% (DC bus efficiency);

2. The middle computer and the lower computer both use 32-bit ARM chip can bus communication, the data transmission speed is fast and the performance is stable.

3. DCAC module adopts space vector modulation technology and digital control, which makes the voltage utilization rate higher and the current harmonic shunt smaller.

4. DCDC module adopts advanced PID control technology and multiple software 1 hardware protection mechanism to ensure the stability of equipment operation;

5. Fast output current conversion, no overshoot phenomenon, avoid the impact of the device on the battery pack.

6. CAN2.0 interface, which can access BMS data of battery pack, can control battery pack status in real time during charging and discharging process.

7. Support the same port and different port battery aging test.

8. Voltage detection adopts 4-wire system.

9. Integrated anti reverse connection module to prevent battery reverse connection;

10. Charge 1 discharge status LED indication. Charge 1 discharge curve analysis diagram. support scan code function.

11.It can be integrated into the production line, cooperate with the production rhythm, and can also be detected separately.

12 Be able to communicate with pack production line, such as OPC,ethernet port and other interface protocols;

13. Support battery pack temperature acquisition.

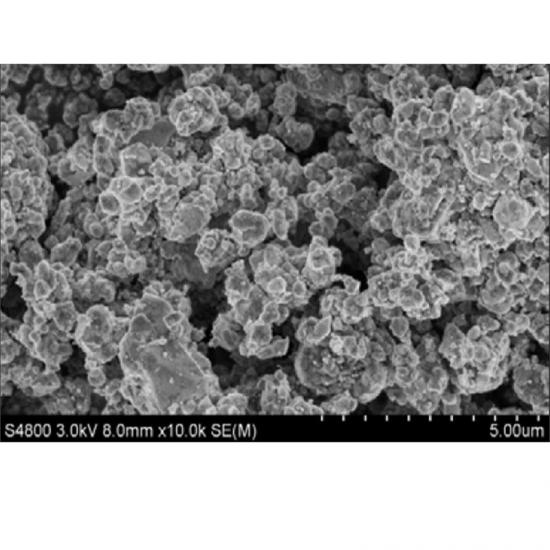

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported