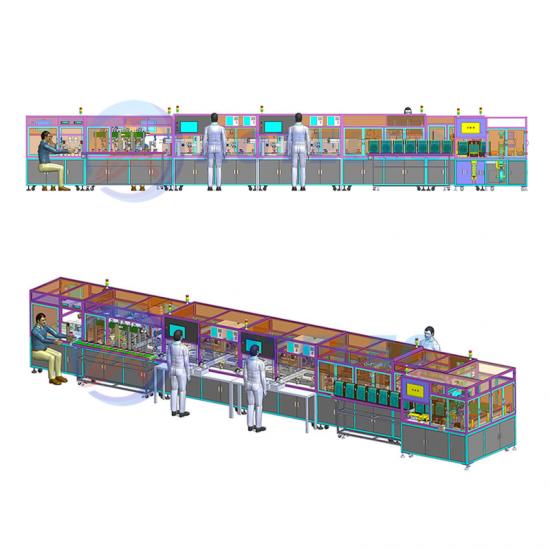

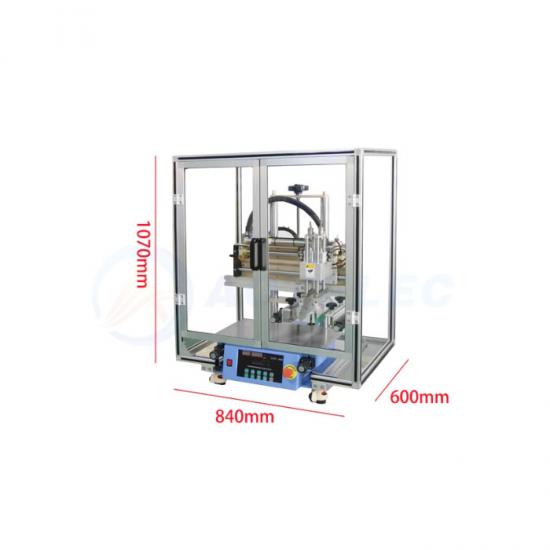

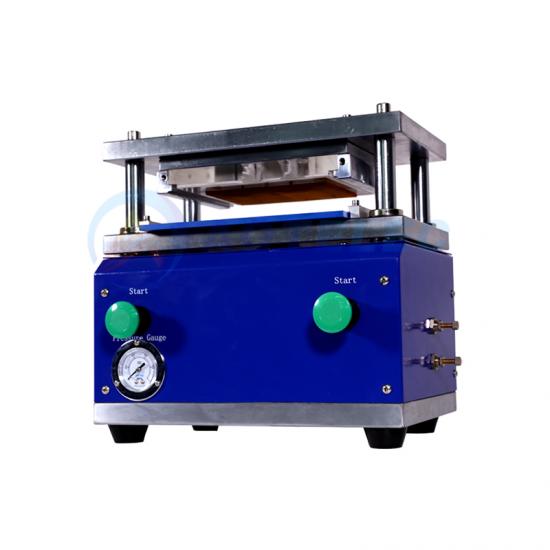

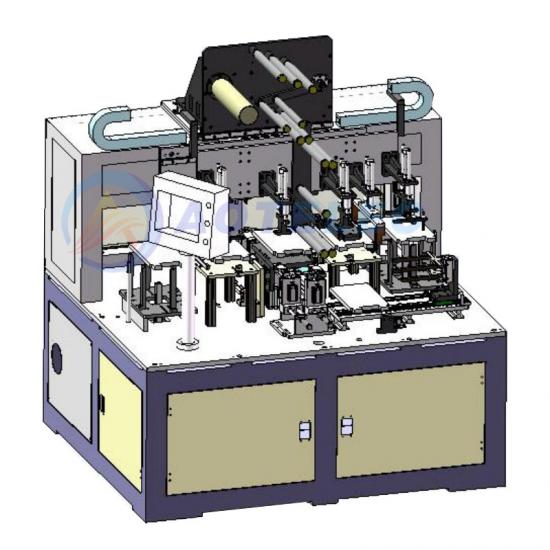

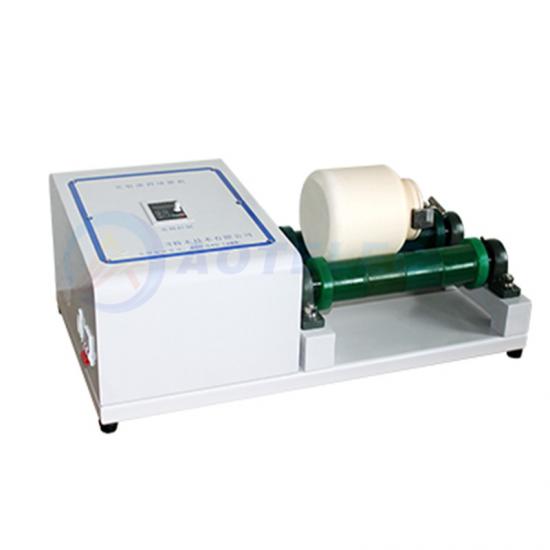

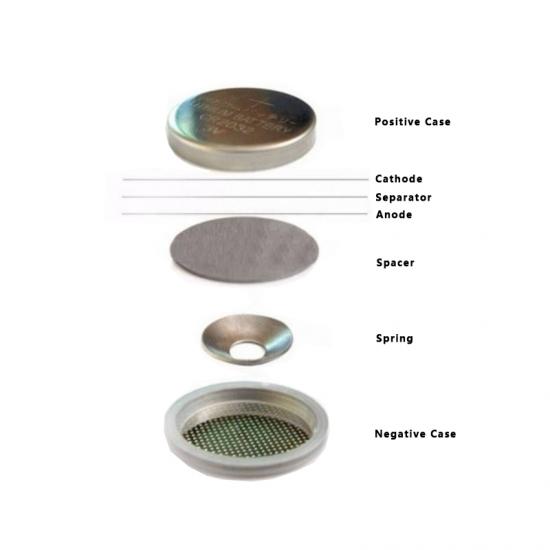

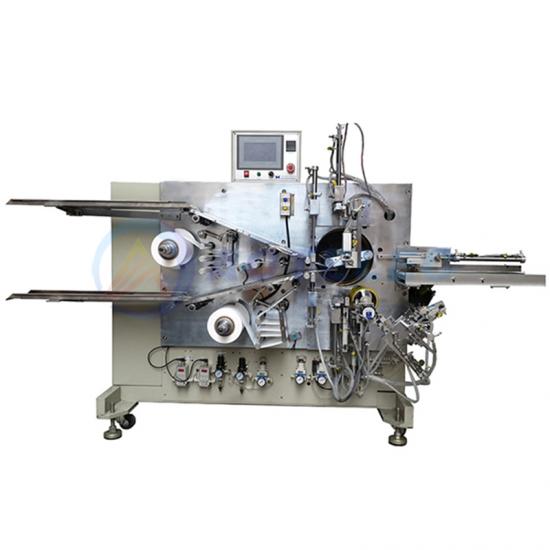

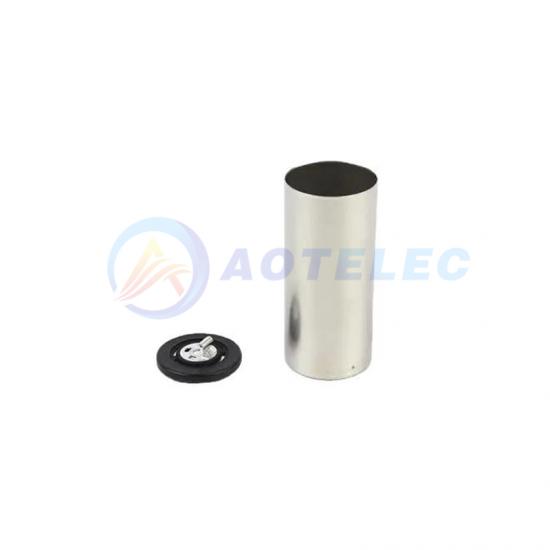

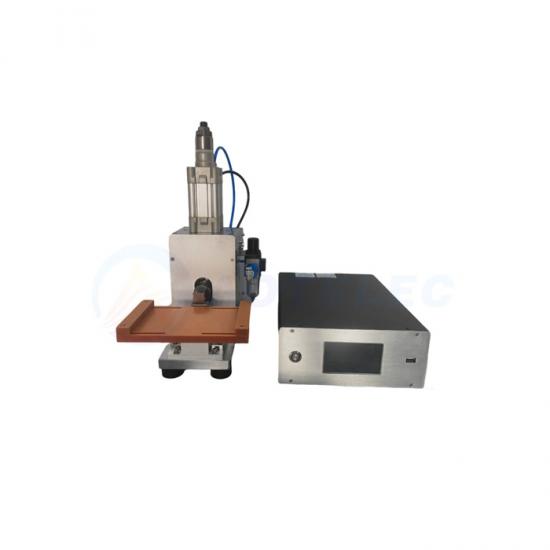

The automatic assembly machine for button batteries can complete the entire process of automatic assembly, filling and sealing based on the assembly process of button batteries in one go. It is driven by an electric motor to achieve the packaging of button batteries, with stable and reliable pressure. By equipping with different fixtures, it can be used for the assembly and sealing of series of button batteries with a diameter of 20mm such as CR2032.

Functional Features:

High production efficiency: Battery assembly efficiency is approximately 1 piece per minute;

High equipment compatibility: It can be linked with robots to achieve automatic loading and unloading of materials;

Precise sealing process: Sealing pressure is closed-loop controlled;

Efficient and convenient operation: The material box can be used immediately after installation, and the entire assembly process is fully automated after a single start-up. Up to 8 batteries can be assembled in one loading.

|

Power Supply |

Single-phase AC 110-220V ±10%, frequency 50/60Hz, power 360W |

|

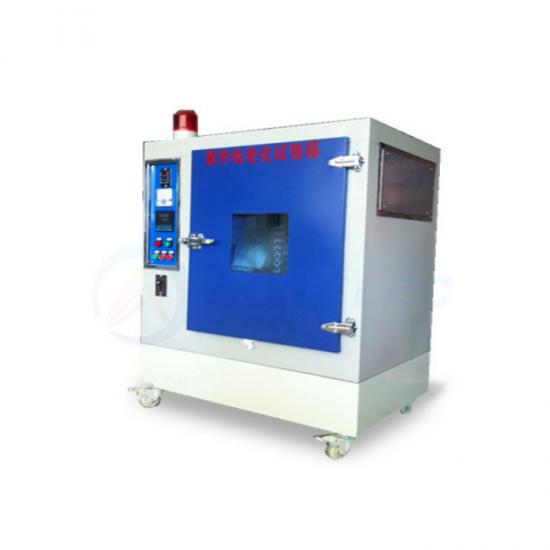

Operating environment |

glove box, drying cabinet, drying room |

|

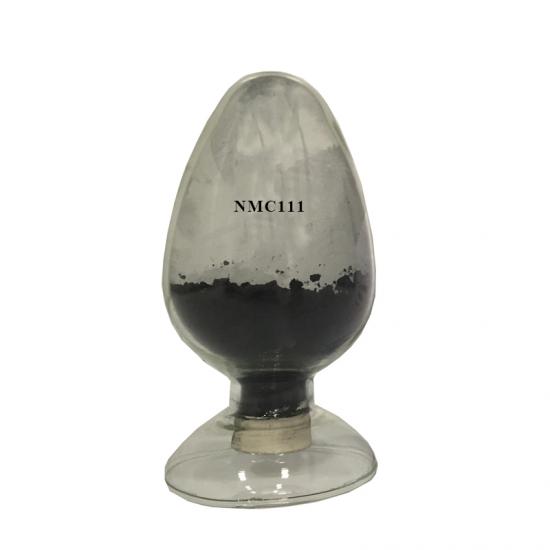

Scope of Application |

CR2032 button cell battery. Other specifications can be customized. |

|

Loading method |

The artificial material boxes are pre-installed and the modules are automatically picked up and conveyed. |

|

Material box positioning |

Accuracy: +0.1mm |

|

Loading box |

Standard configuration: 2 units |

|

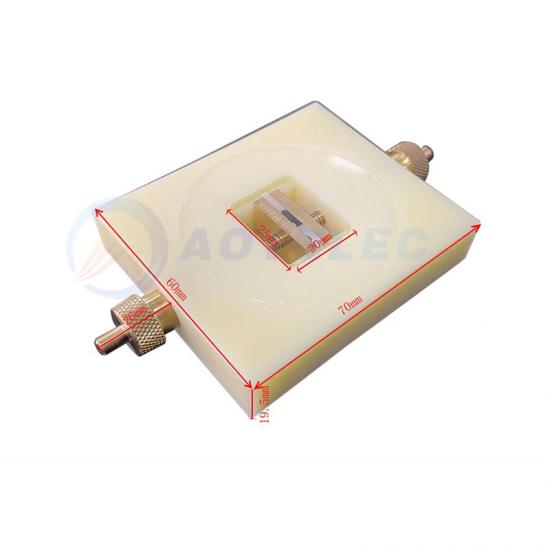

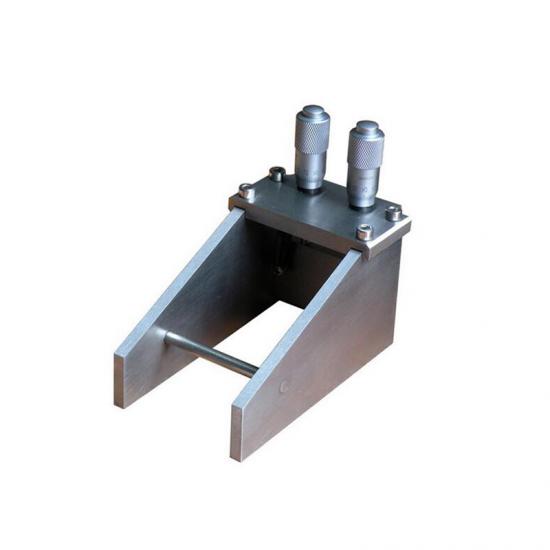

Sealing pressure |

The pressure can be adjusted intermittently. For the CR20 series button batteries, the recommended sealed pressure is 500 - 700 KG, with a maximum of 1000 KG. |

|

Pressure sensor accuracy |

±0.5%F.S |

|

Sealing and holding pressure time |

Max:10s |

|

Equipment speed |

Approximately 1 piece per minute (for reference) |

|

Assembly accuracy |

The overall assembly concentricity is better than ±1mm. |

|

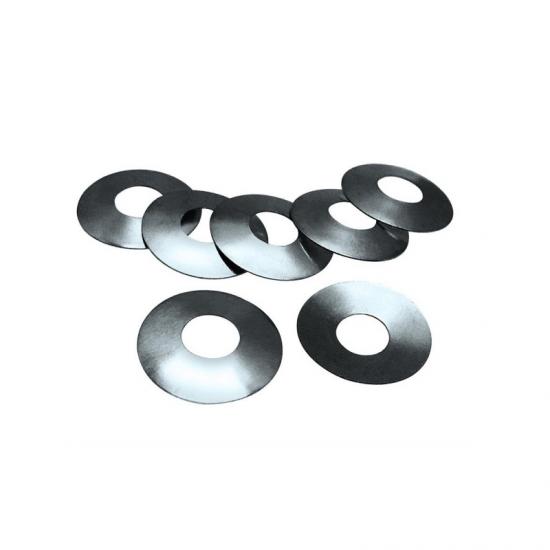

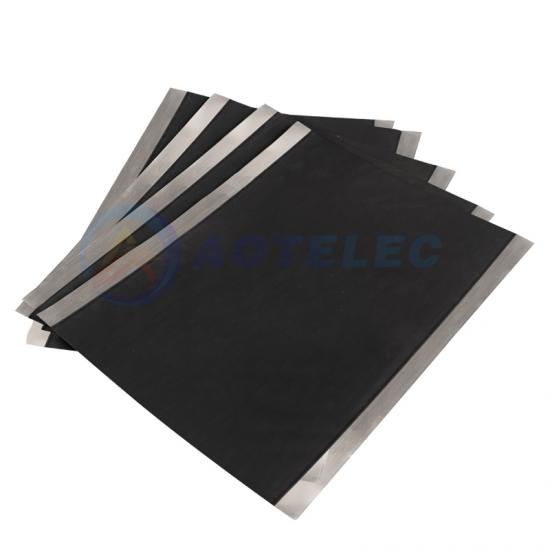

Sealing mold |

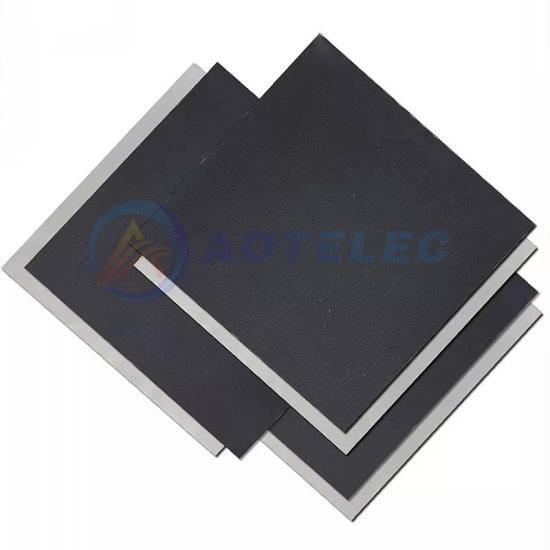

Standard CR2032 battery series sealing mold |

|

Workstation |

1 unit |

|

Injection of liquid |

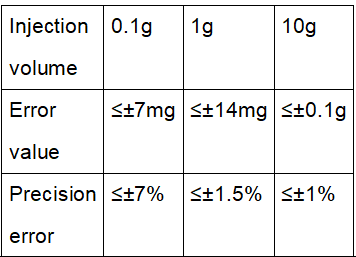

The standard configuration includes 1 peristaltic pump. The minimum single injection volume is 0.01g. The injection accuracy can be referred to the table below (medium: deionized water; injection tube: inner diameter 2mm transparent Teflon tube; injection needle: inner diameter 0.5mm; peristaltic pump rotation speed Max 5 turns/s).

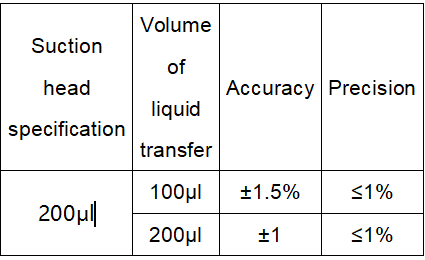

Selection method: Use pipette to dispense liquid, and the liquid dispensing volume can be set; Consumable quantity: 2 pieces Dispensing channels: 2 Dispensing accuracy (single suction, single row)

(For reference only. This is based on test data using deionized water. The actual accuracy is related to the liquid parameters.) Injection type: Multiple injections |

|

Equipment dimensions |

Approximately L650×W350×H600mm |

|

Weight |

Approximately 70 kilograms |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1:How long do you need to prepare my goods?

A: 3-5 days for battery materials. 5-25 days for equipment (based on different model and quantities).

Q2:Can we have our logo or company name to be printed on products or package?

A: Sure. your logo could be printed on your products by hot stamping, printing, embossing, UV coating, silk-screen printing or sticker. In order to explore the market better and provide more convenient services to global customers, we sincerely invite overseas agent to create bright future together.

Q3:How can I install and operate the machine by myself?

A: Our system R&D based on integrated development view. when you get the machine, just need to connect it with the electrical power, then machine can be working. because the English software were installed in this machine. what you need to do is only learning the software usage, and the complete English user manual will be coning to you with the machine.

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported