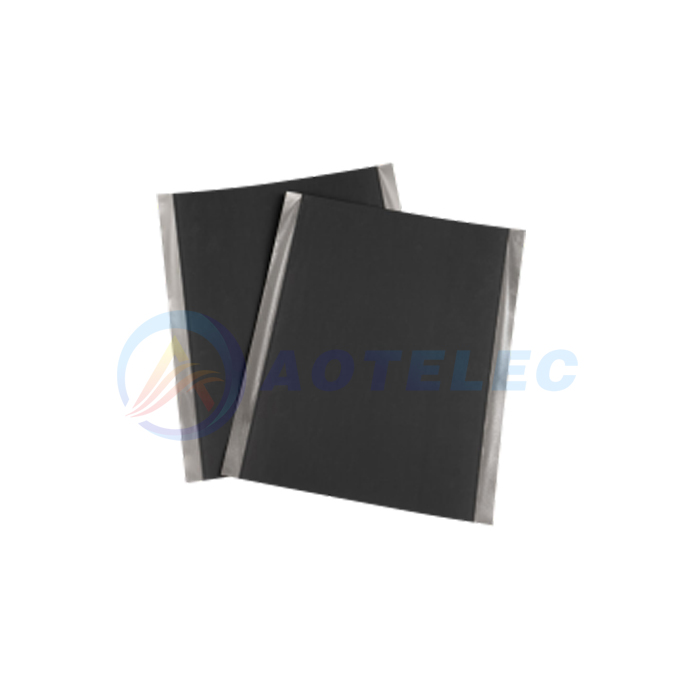

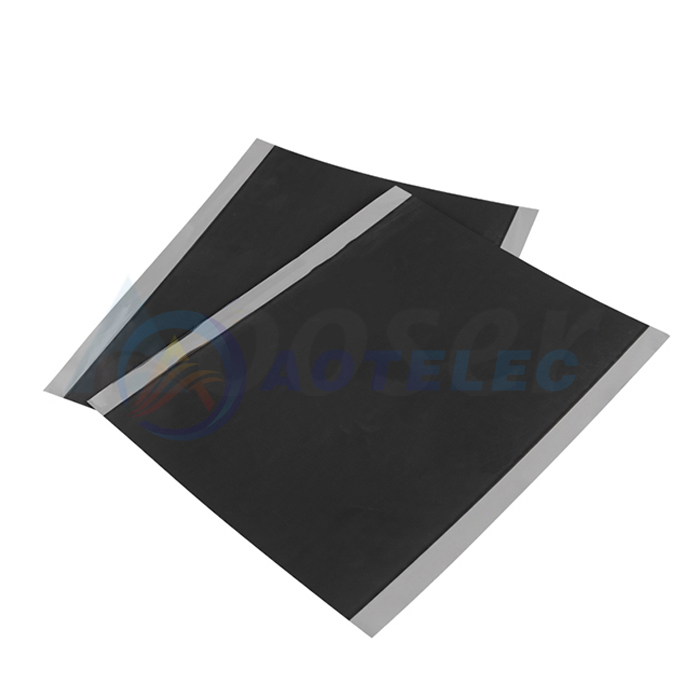

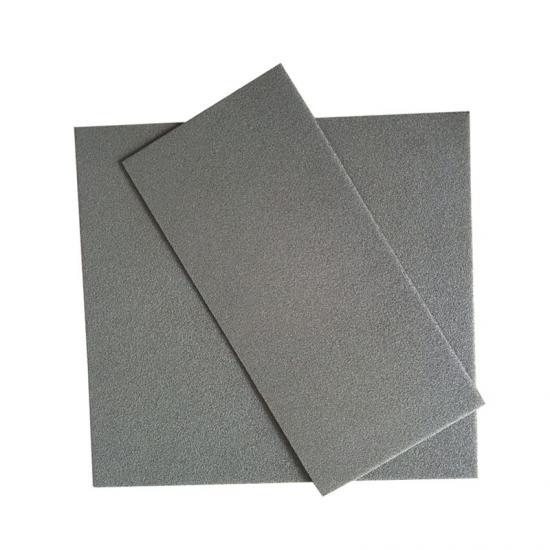

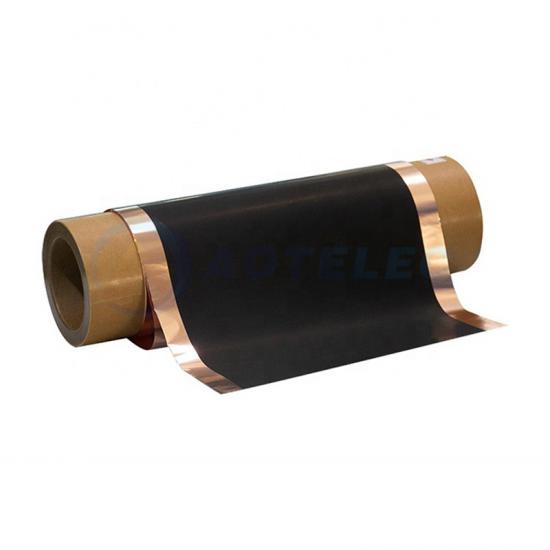

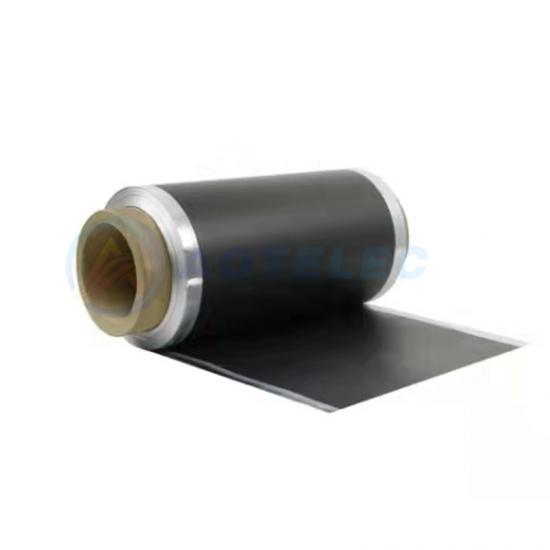

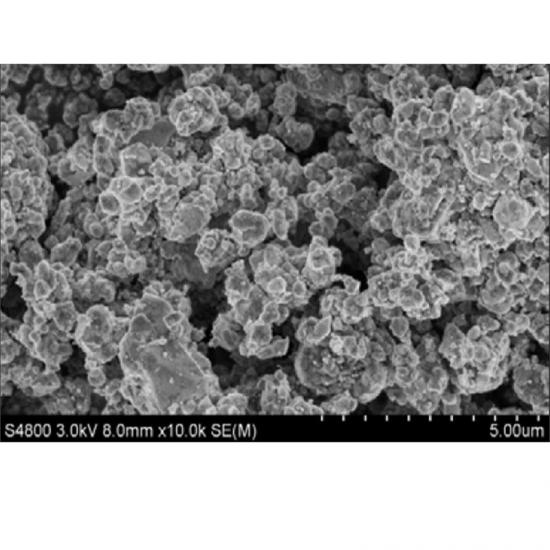

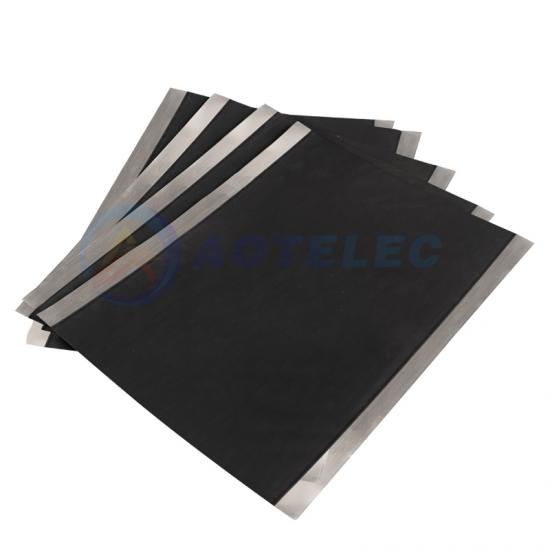

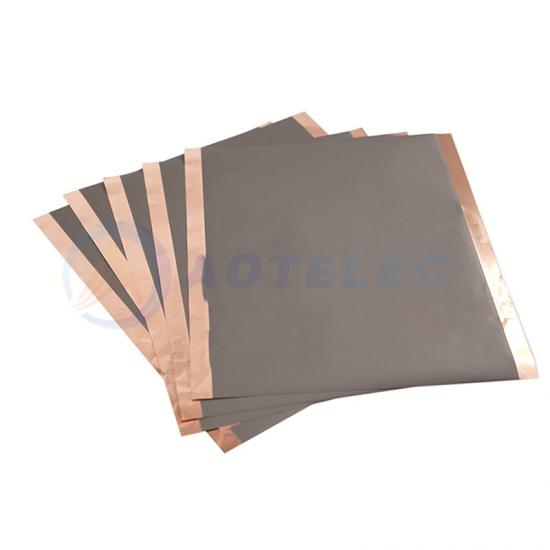

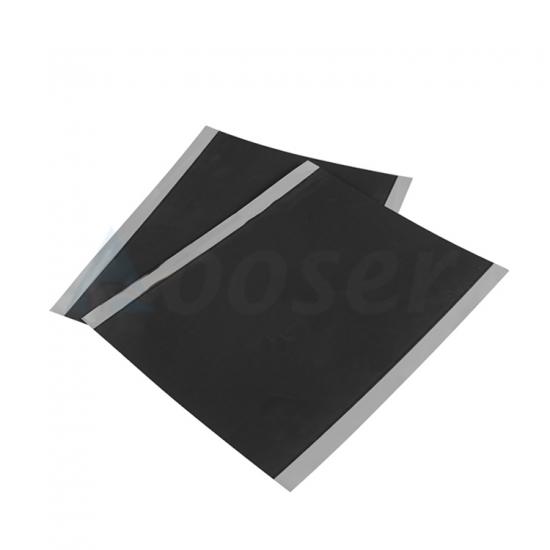

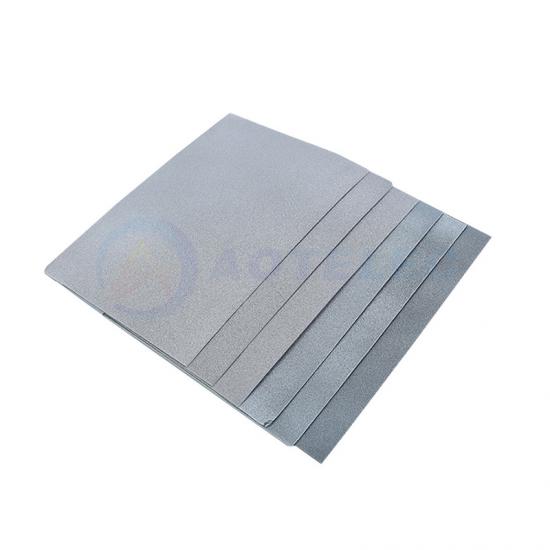

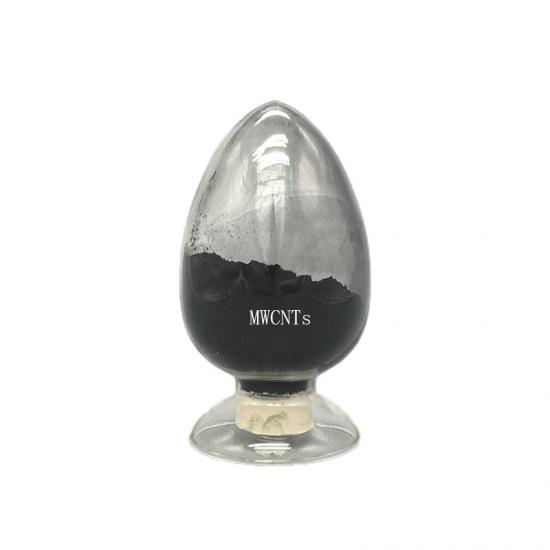

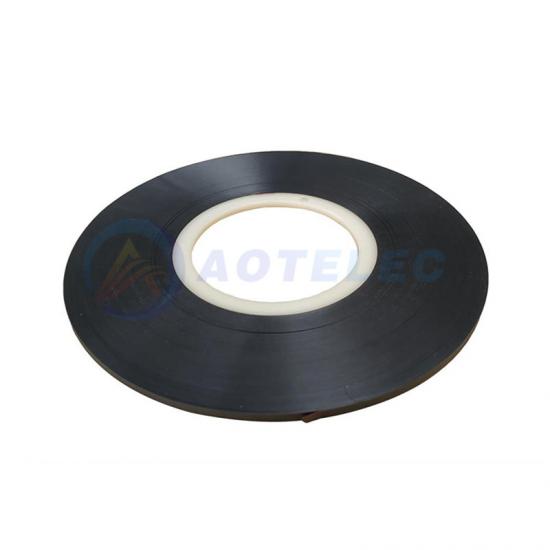

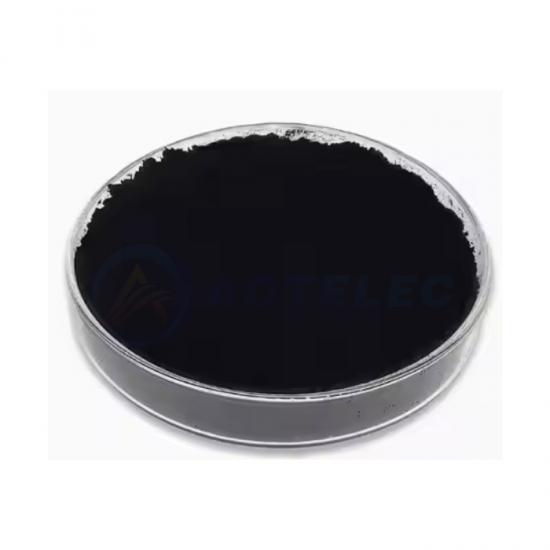

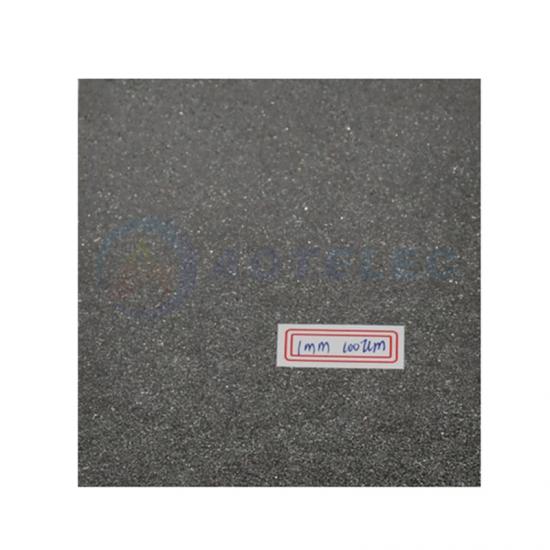

Lithium-sulfur battery is the next generation of high energy density electrochemical energy storage device, the carbon and sulfur composite positive electrode double-sided electrode plate is the key component to improve its performance. This electrode sheet uses advanced carbon-sulfur composite technology to effectively compound highly conductive carbon materials with sulfur through a carefully designed structure. Carbon materials not only provide a good conductive network for sulfur, but also effectively limit the volume expansion of sulfur during charge and discharge through its porous structure, and reduce the shuttle effect of soluble polysulfide ions, thus significantly improving the cycle stability and energy density of the battery.

project

test method

unit

specification

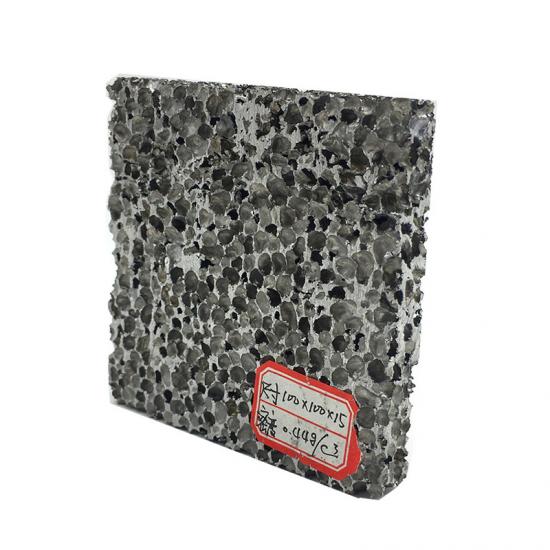

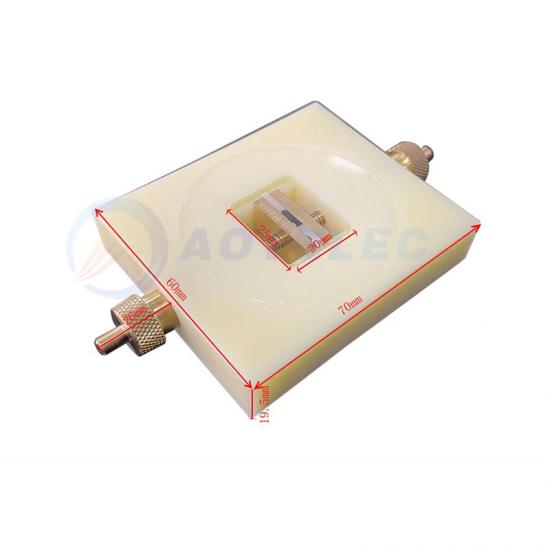

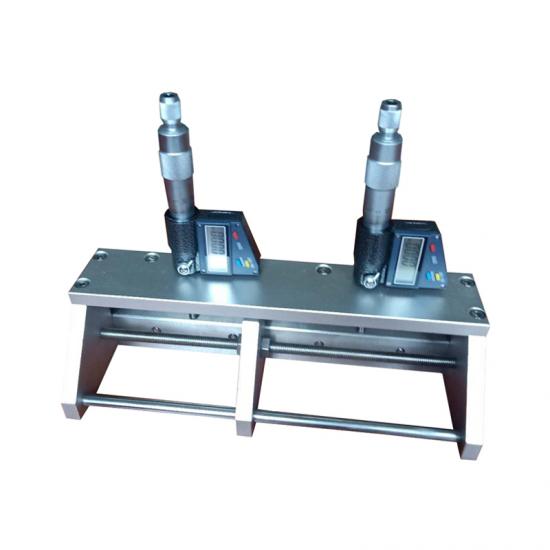

Pole plate size

measurement

mm*mm

50*80

Single-side sulfur load

weight method

mg/cm2

4.1 ±0.1

Initial discharge capacity (I=0.25C; 1C=1000mAh/g)

Constant-current method

mAh/g(0.2C)

≥1400

Initial discharge capacity (I=0.5C; 1C=1000mAh/g)

Constant-current method

mAh/g(0.5C)

≥1200

Specific capacity of secondary discharge:Specific discharge capacity of the second circle (I=0.25C; 1C=1000mAh/g)

Constant-current method

mAh/g(0.2C)

≥1200

Specific capacity of secondary discharge:Specific discharge capacity of the second circle (I=0.5C; 1C=1000mAh/g)

Constant-current method

mAh/g(0.5C)

≥1050

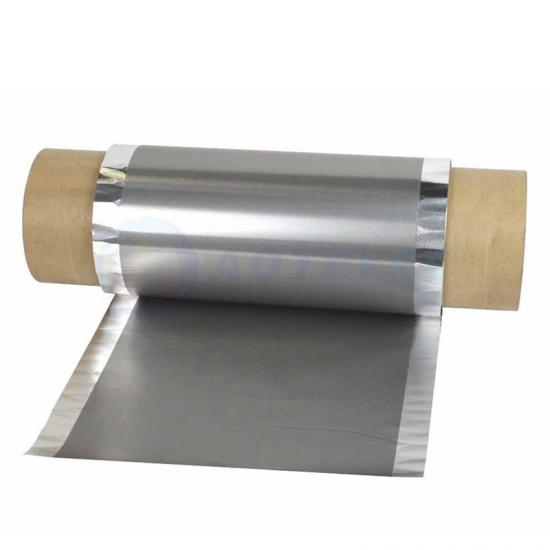

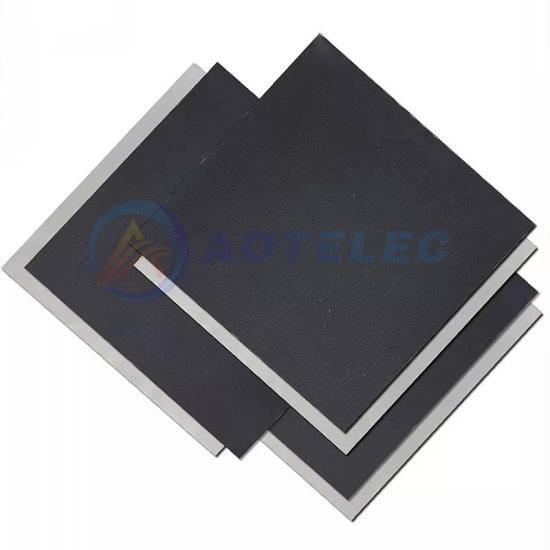

aluminum foil

thickness

um

16

Matters need attention

This product is black pole sheet, easy to absorb moisture, please strictly sealed and stored in dry environment, dry before use.

Double-sided coating, no empty ear.

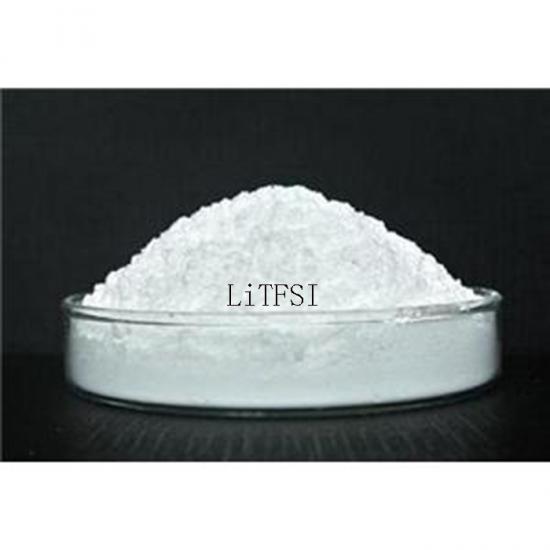

In order to ensure the effectiveness of the pole sheet, it is recommended that the sealed bag be used within one week of opening. It is recommended to use electrolyte DOL: DME=1:1 (v: v), 1Mol/L LiTFSI. The test voltage range is 1.5V-2.6V, and the test temperature is 23±2℃.

Exhibition

Cerificate

![Mg[B(HFIP)4]2](/uploadfile/202401/09/15f1a3930e925703c1b1aaa1833dc2cb_medium.jpg)

IPv6 network supported

IPv6 network supported