-

Nov , 29 2024

Nov , 29 2024

In the realm of battery manufacturing, the precision and quality of battery electrodes are paramount to ensuring the overall performance, safety, and reliability of the final product. Among the various technologies employed in electrode production, Roll-to-Roll (R2R) roll press machines stand out as a critical piece of equipment that significantly influences the physical and electrochemical proper...

View More

-

Dec , 06 2024

Dec , 06 2024

Use Principle and Function of Cylindrical Battery Sealing Machine In modern society, batteries serve as crucial energy supply devices for various electronic products, and their manufacturing process is particularly important. One of the key steps in battery manufacturing is sealing, which determines the battery's sealability and safety. Sealing not only prevents the leakage of electrolyte but also...

View More

-

Dec , 12 2024

Dec , 12 2024

The manufacturing process of pouch cell lithium-ion batteries, involves numerous intricate steps, each critical to ensuring the performance, safety, and reliability of the final product. Among these steps, the utilization of a resting or Standing box (commonly known as a "Vacuum Standing Box" or "静置箱" in Chinese) plays a pivotal role. Given the complexity and significance of this process, it is es...

View More

-

Dec , 26 2024

Dec , 26 2024

Battery roll presses are critical equipment in the manufacturing process of lithium-ion batteries. They play a pivotal role in enhancing the energy density, safety, and lifespan of batteries. Functions of Battery Roll Presses Battery roll presses are primarily used to compress the positive and negative electrode materials, separators, and electrolytes into a tightly packed battery structure. This ...

View More

-

Jan , 02 2025

Jan , 02 2025

Battery manufacturing is a complex and multi-faceted process that involves a series of intricate steps, each requiring specialized machinery to ensure precision, efficiency, and safety. From raw material processing to final assembly and testing, each stage in battery production relies heavily on advanced technology to meet the growing demand for high-performance, reliable, and sustainable energy s...

View More

-

Jan , 09 2025

Jan , 09 2025

In the production of cylindrical batteries, spot welding machines play a pivotal role, ensuring the quality and reliability of the welding processes that are crucial for battery performance. 1.Role of Spot Welding Machines in Cylindrical Battery Production Cylindrical batteries, as an important type of lithium-ion batteries, have welding as a particularly critical step in their manufacturing proce...

View More

-

Feb , 07 2025

Feb , 07 2025

Battery manufacturing is a highly specialized and intricate process that demands meticulous attention to detail, precision, and cleanliness. One critical component in ensuring the quality and safety of batteries during production is the glove box. This enclosed, controlled environment plays a pivotal role in various stages of battery fabrication, from material handling to assembly and testing. 1、U...

View More

-

Feb , 21 2025

Feb , 21 2025

In the silent revolution of energy storage, a remarkable piece of industrial machinery works with micron-level precision to create the power cores of our electrified future. The pouch cell winding machine, often overlooked outside manufacturing circles, plays a pivotal role in determining the performance, safety, and cost-effectiveness of the lithium-ion batteries powering everything from smartpho...

View More

-

Mar , 06 2025

Mar , 06 2025

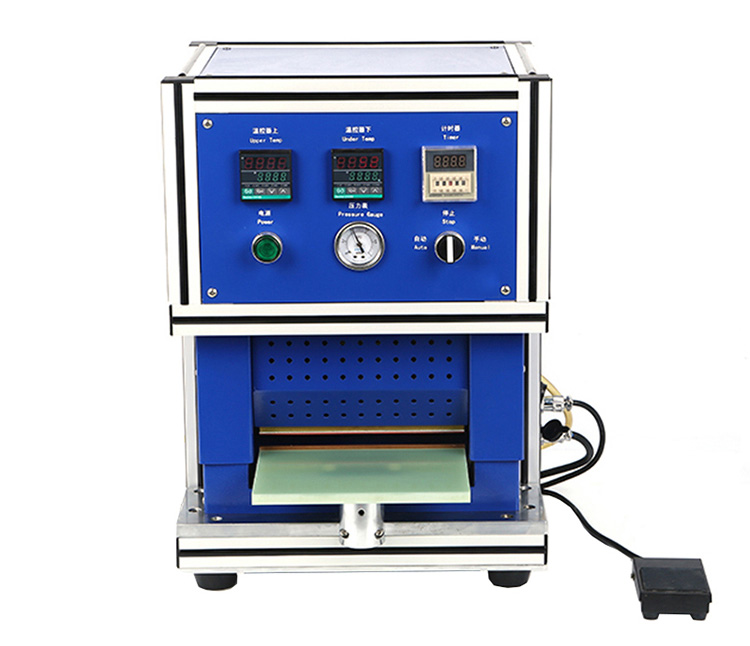

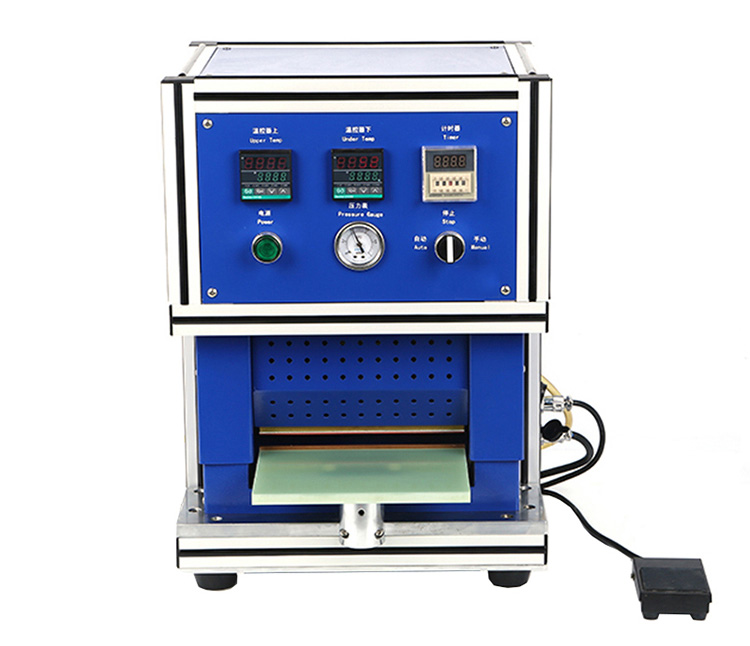

Introduction In the rapidly evolving field of energy storage, pouch cell batteries have emerged as a critical technology due to their lightweight design, high energy density, and flexibility in shape. A pivotal step in their manufacturing process is the sealing of the battery pouch, which directly impacts performance, safety, and longevity. Sealing machines play a vital role in ensuring her...

View More

-

Mar , 13 2025

Mar , 13 2025

Introduction In the rapidly evolving battery industry, viscosity testing has emerged as a cornerstone of quality control, particularly in the production of lithiumion batteries. Electrode slurries, electrolytes, and other battery components require precise viscosity management to ensure optimal performance, safety, and longevity. Viscosity testing instruments, such as rotational viscometers and rh...

View More

-

Mar , 21 2025

Mar , 21 2025

Introduction In the heart of every lithium-ion battery lies its electrodes—carefully engineered layers of active materials that determine energy density, cycle life, and safety. The process of transforming raw electrode slurries into uniform, defect-free coatings on metal foils relies on two unsung heroes: doctor blades and coating applicators. These precision tools are pivotal in defining the thi...

View More

-

Mar , 27 2025

Mar , 27 2025

Introduction In the intricate process of battery manufacturing, thermal treatment plays a decisive role in defining the structural, electrochemical, and mechanical properties of materials. Muffle furnaces and hightemperature furnaces are indispensable tools for processes such as electrode sintering, solidstate electrolyte synthesis, and precursor calcination. 1. Fundamental Differences Between Muf...

View More

Nov , 29 2024

Nov , 29 2024

Dec , 06 2024

Dec , 06 2024

Dec , 12 2024

Dec , 12 2024

Dec , 26 2024

Dec , 26 2024

Jan , 02 2025

Jan , 02 2025

Jan , 09 2025

Jan , 09 2025

Feb , 07 2025

Feb , 07 2025

Feb , 21 2025

Feb , 21 2025

Mar , 06 2025

Mar , 06 2025

Mar , 13 2025

Mar , 13 2025

Mar , 21 2025

Mar , 21 2025

Mar , 27 2025

Mar , 27 2025