-

Apr , 10 2025

Apr , 10 2025

1、what is lithium battery coating machine Lithium battery coater is a special equipment for coating the paste made of the mixture of active substances, binders, solvents, etc. uniformly on the surface of metal foils (such as copper foil, aluminum foil). The coating process is one of the key links of lithium battery production, which directly affects the performance and quality of the battery. By p...

View More

-

Apr , 24 2025

Apr , 24 2025

1. Overview of Battery Coating Machine (1) What is a battery coating machine The battery coating machine, also known as the lithium battery coating machine, is a kind of mechanical equipment specifically used for the production of lithium-ion battery electrode sheets. It evenly coats the slurry on substrates such as aluminum foil or copper foil through a specific coating process. After drying and ...

View More

-

Jun , 19 2025

Jun , 19 2025

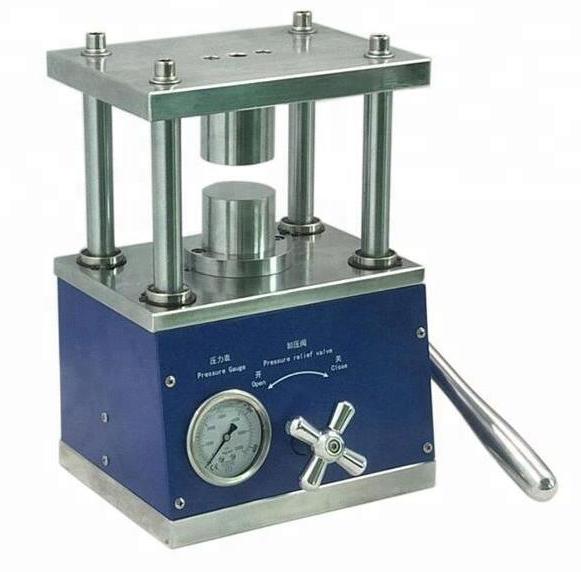

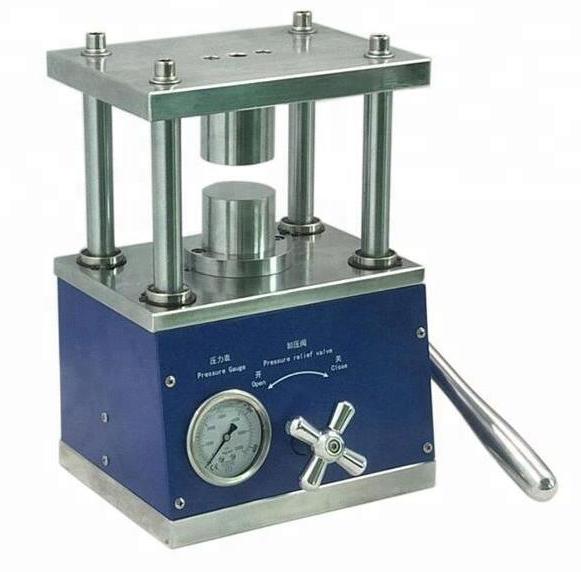

In the field of battery research and development, the laboratory battery powder press machine stands as a cornerstone instrument, pivotal for fabricating battery electrodes and prototypes. Widely used in fields such as powder metallurgy, cement, catalysis, silicon hydrochloric acid, batteries, ceramics, and universities for component analysis. Powder is compressed into test pieces and adapted to v...

View More

-

Jul , 02 2025

Jul , 02 2025

In the field of battery research and production, ensuring the sealing of batteries is of utmost importance. For coin cell batteries, an efficient and reliable sealing device can significantly enhance production efficiency and product quality. The Electric Coin Cell Crimping Machine for Lab coin cell Battery Sealing is such a highly regarded device. Working principle The crimping machine employs ad...

View More

-

Jul , 10 2025

Jul , 10 2025

In the intricate ecosystem of battery manufacturing, high-temperature furnaces stand as unsung workhorses, enabling the synthesis of materials that underpin the performance, safety, and efficiency of modern batteries. From lithium-ion to next-gen solid-state systems, these specialized heating devices facilitate thermal processes that transform raw powders into functional components with precisely ...

View More

-

Jul , 17 2025

Jul , 17 2025

In the realm of cylindrical battery manufacturing, the grooving machine stands as a pivotal piece of equipment, playing an indispensable role in ensuring the structural integrity, sealing performance, and overall quality of the final product. As cylindrical batteries, such as lithium-ion and nickel-metal hydride batteries, are widely used in various fields including consumer electronics, electric ...

View More

-

Aug , 07 2025

Aug , 07 2025

In the fields of research and testing of new energy devices such as lithium-ion batteries and supercapacitors, a reliable and precisely structured battery case is of vital importance. The 304ss Meshed Coin Cell Cases CR20XX series, with its outstanding material properties, unique grid design and wide adaptability, has become the preferred solution for research institutions and enterprise laborator...

View More

-

Aug , 28 2025

Aug , 28 2025

In the high-stakes world of lithium-ion battery production, precision, speed, and reliability are not just desirable—they are absolutely critical. Every step in the manufacturing process, from electrode coating to final assembly, must be executed with flawless accuracy to ensure the safety, performance, and longevity of the final product. One of the most pivotal steps in this chain...

View More

-

Sep , 11 2025

Sep , 11 2025

1. Introduction In the R&D and small-batch production of lithium-ion batteries, the uniformity, bubble-free property, and process stability of raw material mixing directly affect the performance of electrode slurry, which in turn is related to the battery's energy density and cycle life. As a key pretreatment equipment, lab-scale vacuum mixers need to meet the technical requirements of high pr...

View More

-

Sep , 25 2025

Sep , 25 2025

In the race to develop higher-performance, safer, and more sustainable batteries—from lithium-ion (LIB) to solid-state (SSB) and sodium-ion (SIB) systems—battery laboratories rely on precision equipment to translate chemical formulas into functional electrode prototypes. Among these tools, the slot die coater stands out as a game-changer: its ability to deposit uniform, reproducible thin films of ...

View More

-

Oct , 16 2025

Oct , 16 2025

Pouch batteries have become a cornerstone of modern energy storage, powering devices from smartphones to electric vehicles (EVs) due to their high energy density, flexible form factor, and lightweight design. At the heart of pouch battery production lies a critical piece of equipment: the winding machine. This specialized tool transforms flat electrode sheets and separators into the compact, cylin...

View More

-

Oct , 23 2025

Oct , 23 2025

Carbon paper—often referred to as carbon fiber paper (CFP) or porous carbon substrate—has emerged as a critical material in modern battery systems, thanks to its unique combination of high electrical conductivity, structural flexibility, porous architecture, and chemical stability. Unlike traditional paper, carbon paper is manufactured from carbon fibers (typically polyacrylonitrile-based or pitch...

View More

Apr , 10 2025

Apr , 10 2025

Apr , 24 2025

Apr , 24 2025

Jun , 19 2025

Jun , 19 2025

Jul , 02 2025

Jul , 02 2025

Jul , 10 2025

Jul , 10 2025

Jul , 17 2025

Jul , 17 2025

Aug , 07 2025

Aug , 07 2025

Aug , 28 2025

Aug , 28 2025

Sep , 11 2025

Sep , 11 2025

Sep , 25 2025

Sep , 25 2025

Oct , 16 2025

Oct , 16 2025

Oct , 23 2025

Oct , 23 2025