-

Nov , 29 2024

Nov , 29 2024

In the realm of battery manufacturing, the precision and quality of battery electrodes are paramount to ensuring the overall performance, safety, and reliability of the final product. Among the various technologies employed in electrode production, Roll-to-Roll (R2R) roll press machines stand out as a critical piece of equipment that significantly influences the physical and electrochemical proper...

View More

-

Dec , 26 2024

Dec , 26 2024

Battery roll presses are critical equipment in the manufacturing process of lithium-ion batteries. They play a pivotal role in enhancing the energy density, safety, and lifespan of batteries. Functions of Battery Roll Presses Battery roll presses are primarily used to compress the positive and negative electrode materials, separators, and electrolytes into a tightly packed battery structure. This ...

View More

-

Jan , 02 2025

Jan , 02 2025

Battery manufacturing is a complex and multi-faceted process that involves a series of intricate steps, each requiring specialized machinery to ensure precision, efficiency, and safety. From raw material processing to final assembly and testing, each stage in battery production relies heavily on advanced technology to meet the growing demand for high-performance, reliable, and sustainable energy s...

View More

-

Mar , 06 2025

Mar , 06 2025

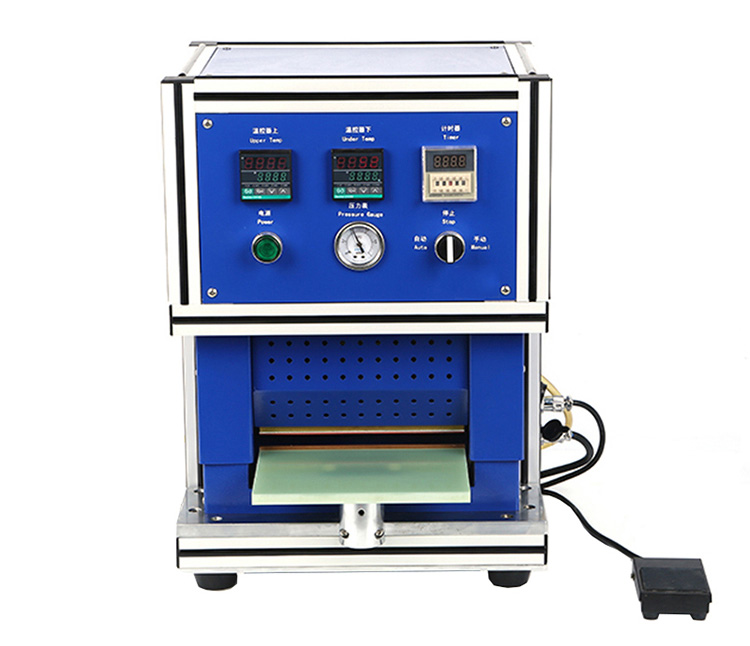

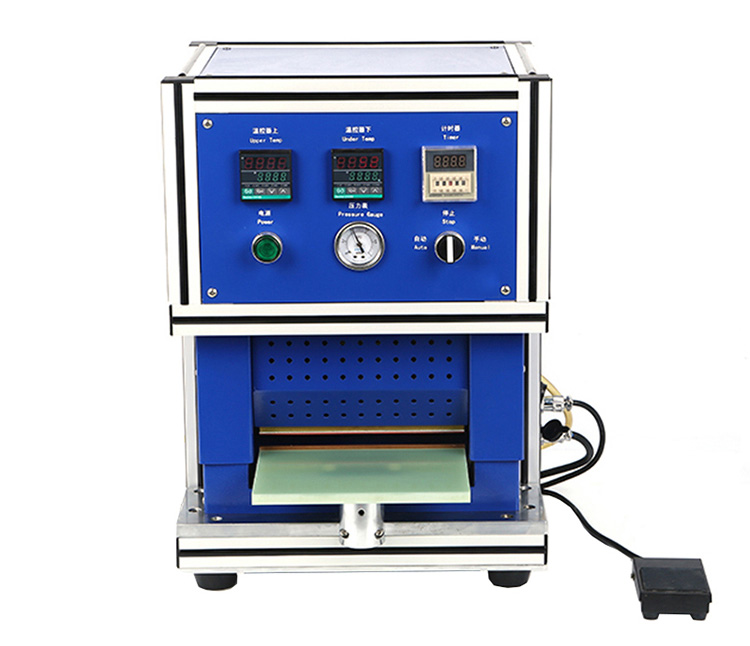

Introduction In the rapidly evolving field of energy storage, pouch cell batteries have emerged as a critical technology due to their lightweight design, high energy density, and flexibility in shape. A pivotal step in their manufacturing process is the sealing of the battery pouch, which directly impacts performance, safety, and longevity. Sealing machines play a vital role in ensuring her...

View More

-

Mar , 21 2025

Mar , 21 2025

Introduction In the heart of every lithium-ion battery lies its electrodes—carefully engineered layers of active materials that determine energy density, cycle life, and safety. The process of transforming raw electrode slurries into uniform, defect-free coatings on metal foils relies on two unsung heroes: doctor blades and coating applicators. These precision tools are pivotal in defining the thi...

View More

-

Apr , 17 2025

Apr , 17 2025

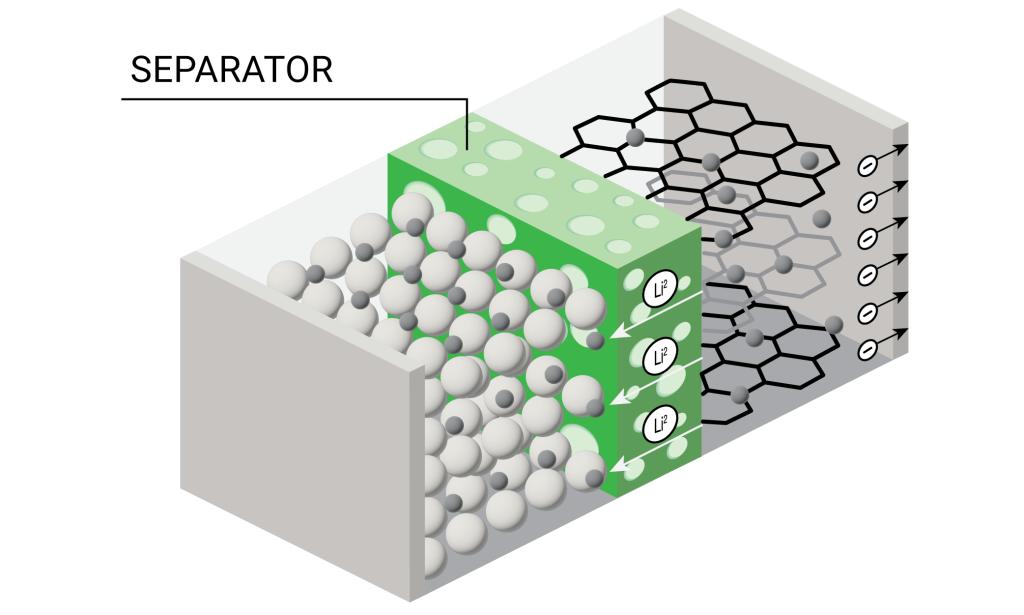

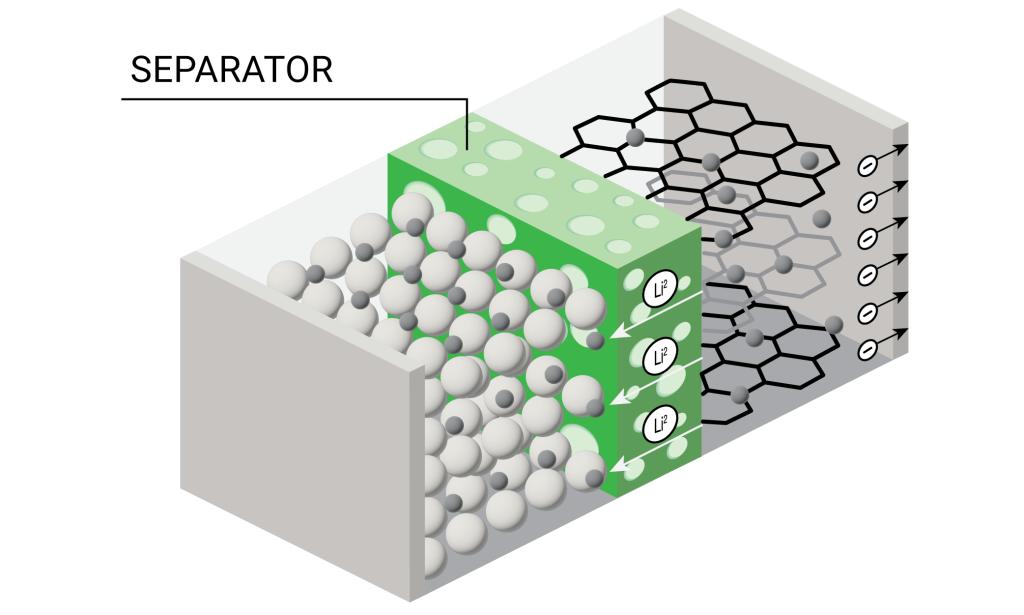

1、The definition and essence of lithium battery separators The lithium battery separator is a thin film material with a microporous structure, located between the positive and negative electrodes of the lithium battery. Its core function is to physically isolate the positive and negative electrodes to prevent direct contact between the two electrodes and cause a short circuit. At the same time, it...

View More

-

Apr , 24 2025

Apr , 24 2025

1. Overview of Battery Coating Machine (1) What is a battery coating machine The battery coating machine, also known as the lithium battery coating machine, is a kind of mechanical equipment specifically used for the production of lithium-ion battery electrode sheets. It evenly coats the slurry on substrates such as aluminum foil or copper foil through a specific coating process. After drying and ...

View More

-

May , 29 2025

May , 29 2025

The performance of the separator is deeply related to the safety of lithium batteries, such as the tensile strength, thermal shrinkage rate, puncture strength, etc. of the separator, which are directly related to the performance of the battery cell. Ceramic coatings, as the most widely used coatings on the market, have the advantages of good stability and low thermal shrinkage. This article will b...

View More

-

Jun , 19 2025

Jun , 19 2025

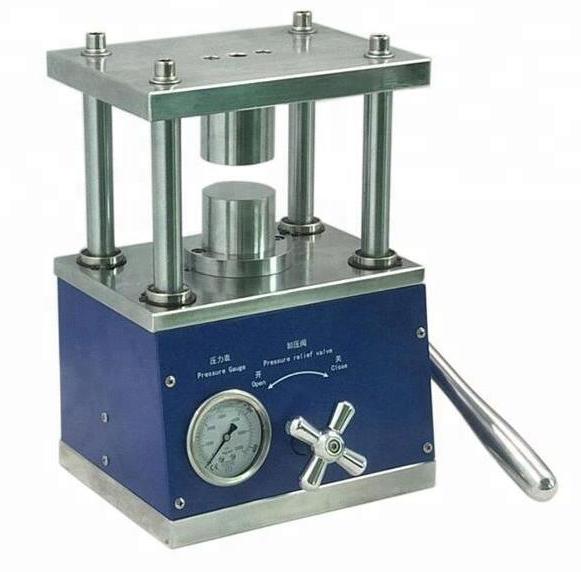

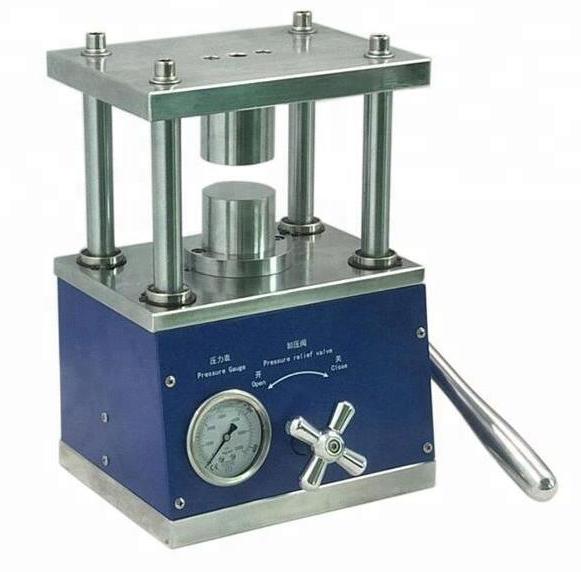

In the field of battery research and development, the laboratory battery powder press machine stands as a cornerstone instrument, pivotal for fabricating battery electrodes and prototypes. Widely used in fields such as powder metallurgy, cement, catalysis, silicon hydrochloric acid, batteries, ceramics, and universities for component analysis. Powder is compressed into test pieces and adapted to v...

View More

-

Jun , 26 2025

Jun , 26 2025

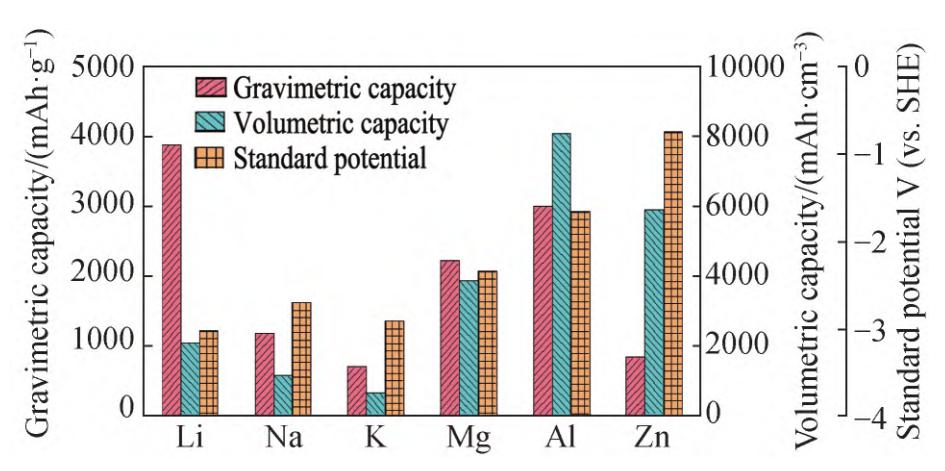

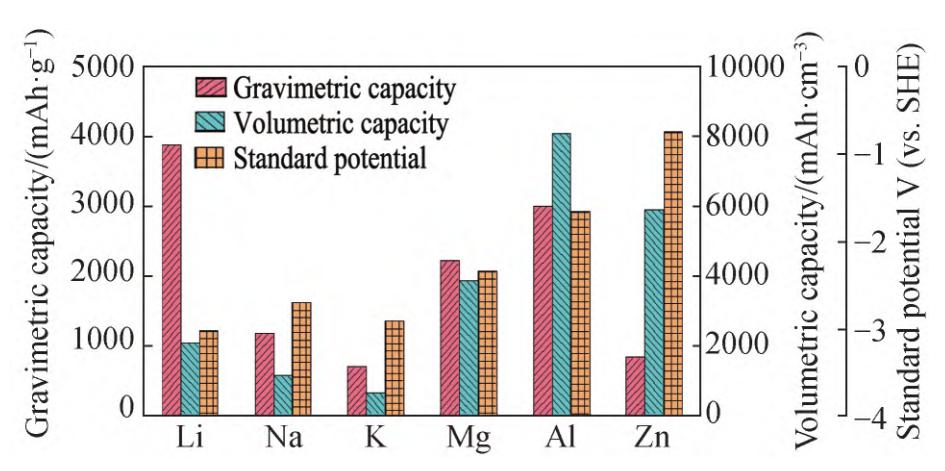

The existing secondary batteries have the characteristics of high energy density and good cycling performance. However, the commonly used organic electrolytes are toxic and flammable, which pose certain safety risks. Moreover, the existing electrode materials are limited in resources and have high costs, restricting their large-scale application in the energy storage field. Using water-based elect...

View More

-

Jul , 17 2025

Jul , 17 2025

In the realm of cylindrical battery manufacturing, the grooving machine stands as a pivotal piece of equipment, playing an indispensable role in ensuring the structural integrity, sealing performance, and overall quality of the final product. As cylindrical batteries, such as lithium-ion and nickel-metal hydride batteries, are widely used in various fields including consumer electronics, electric ...

View More

-

Aug , 07 2025

Aug , 07 2025

In the fields of research and testing of new energy devices such as lithium-ion batteries and supercapacitors, a reliable and precisely structured battery case is of vital importance. The 304ss Meshed Coin Cell Cases CR20XX series, with its outstanding material properties, unique grid design and wide adaptability, has become the preferred solution for research institutions and enterprise laborator...

View More

Nov , 29 2024

Nov , 29 2024

Dec , 26 2024

Dec , 26 2024

Jan , 02 2025

Jan , 02 2025

Mar , 06 2025

Mar , 06 2025

Mar , 21 2025

Mar , 21 2025

Apr , 17 2025

Apr , 17 2025

Apr , 24 2025

Apr , 24 2025

May , 29 2025

May , 29 2025

Jun , 19 2025

Jun , 19 2025

Jun , 26 2025

Jun , 26 2025

Jul , 17 2025

Jul , 17 2025

Aug , 07 2025

Aug , 07 2025