-

May , 09 2020

What is the thickness of aluminum foil and copper foil for lithium battery? With the rapid development of lithium batteries in recent years, current collectors for lithium batteries have also developed rapidly. The positive electrode aluminum foil has been reduced from 16um to 14um, then reduced to 12um in previous years, and now many battery manufacturers have already mass-produced 10um aluminum ...

View More

-

May , 10 2020

What are the requirements for surface roughness of copper and aluminum foils for lithium batteries? For the lithium ion battery current collector, in addition to its thickness and weight having an influence on the battery, the surface performance of the current collector has a greater influence on the production and performance of the battery. Especially for the negative electrode current collecto...

View More

-

Apr , 26 2022

As a new generation of green high-energy rechargeable batteries, lithium-ion batteries have the characteristics of high voltage, high energy density, good cycle performance, small self-discharge, and no memory effect. The main way to improve the specific energy of lithium-ion batteries is to use higher-capacity positive and anode battery materials, thinner separator paper, thinner copper foil and ...

View More

-

May , 13 2022

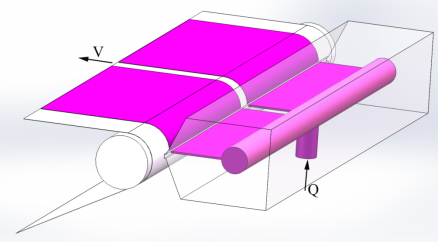

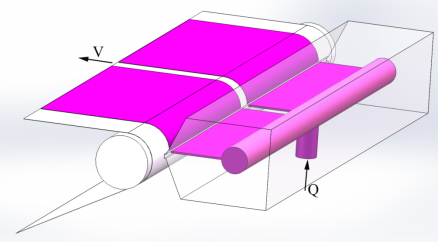

Pole piece coating generally refers to a process in which a uniformly stirred slurry is evenly coated on the current collector, and the organic solvent in the slurry is dried. The effect of coating has an important impact on battery capacity, internal resistance, cycle life and safety. The reasons for wrinkling during the coating process are as follows: 1. First of all, the installation accuracy o...

View More

-

Jun , 28 2022

The lithium-ion battery slurry coating process is a process in which a non-Newtonian fluid contacts, flows, and solidifies a solid substrate.Different from the contact between the solid state, the lithium battery slurry is sprayed from the coating head and coated on the copper foil and aluminum foil, and there will be dynamic changes in the liquid state, including adhesion, wetting, leveling, rebo...

View More

-

Jul , 07 2022

The principle of ultrasonic metal welding is a special method of using the mechanical vibration energy of ultrasonic frequency to connect the same metal or dissimilar metal. When the metal is ultrasonically welded, it neither transmits current to the workpiece nor applies a high temperature heat source to the workpiece, but under static pressure, the frame vibration energy is converted into fricti...

View More

-

Nov , 23 2022

There are several types of wrinkling of the lithium battery electrode sheets, the wavy edge of the lithium battery electrode, the wrinkle of the lithium battery electrode, and the wrinkling of the paint area. Of course, there are several degrees of wrinkling severity. Wrinkles in the coating area of the electrode will cause the surface of the bare cell to be uneven, and the stress conce...

View More

-

Oct , 26 2023

In the manufacturing process of lithium-ion batteries, there are three crucial items that must be strictly controlled:One is dust.The second is metal particles.The third is moisture; Dust and metal particles that are not properly controlled can directly lead to safety accidents such as internal short circuits, fires, and combustion within the battery; If moisture is not effectively controlled, it ...

View More

-

Dec , 05 2023

The current collector is one of the indispensable components in lithium-ion batteries. It can not only carry active substances, but also collect and output the current generated by electrode active substances, which is beneficial for reducing the internal resistance of lithium-ion batteries, improving the Coulombic efficiency, cycle stability, and rate performance of batteries. At present, the pos...

View More

-

May , 09 2024

May , 09 2024

Coating process is a process based on the study of fluid properties, which involves coating one or more layers of liquid onto a substrate. The substrate is usually a flexible film or backing paper, and then the coated liquid coating is dried in an oven or cured to form a special functional film layer. The coating process of lithium-ion power battery electrodes has its own characteristics: d...

View More

-

Sep , 26 2024

Sep , 26 2024

In the rapidly evolving landscape of the energy storage industry, pouch cell batteries have emerged as a prominent choice due to their high energy density, exceptional safety features, and flexibility in design. At the core of the manufacturing process of these batteries lies the Aluminum laminated film forming machine, a vital piece of equipment that ensures the precision and efficiency of batter...

View More

-

Sep , 19 2025

Sep , 19 2025

In the high-stakes race to develop longer-lasting, safer, and more efficient batteries—for electric vehicles (EVs), grid storage, and portable electronics—success often hinges on a tool so small it can fit in the palm of a hand: the battery electrolyte pipette. While headline-grabbing innovations like solid-state chemistries or silicon anodes dominate media coverage, these precision instruments qu...

View More

May , 09 2024

May , 09 2024

Sep , 26 2024

Sep , 26 2024

Sep , 19 2025

Sep , 19 2025