-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.comThere are several types of wrinkling of the lithium battery electrode sheets, the wavy edge of the lithium battery electrode, the wrinkle of the lithium battery electrode, and the wrinkling of the paint area.

Of course, there are several degrees of wrinkling severity. Wrinkles in the coating area of the electrode will cause the surface of the bare cell to be uneven, and the stress concentration may cause damage to the battery separator , causing micro-short circuit or short circuit of the cell. Wrinkles at the tabs will affect the welding strength of the tabs, resulting in poor welding or increasing the resistance of the battery. The battery will heat up quickly during charging and discharging, and the cycle life will decay faster. Pole ear creases may also puncture the septum, causing a short circuit. The active material is more likely to fall off at the wrinkled edge of the pole piece, and the exposed foil is a serious quality problem for the pole piece. To sum up, the wrinkling of the pole piece must be well controlled. There are many reasons for the wrinkling of the pole piece, including the electrode material itself and the equipment accuracy. The following will analyze them one by one.

Copper foil and aluminum foil are both made of copper and aluminum blocks through extrusion and sheeting, which have good metal processing and ductility. When the pole piece is rolled, the active materials are squeezed against each other, and a certain pressure is applied to the copper foil and aluminum foil, which will produce a certain extension. During rolling, the part not coated with active matter does not stretch, but the pole piece with active matter stretches under the action of the roller pressure. The stretching of the two positions is inconsistent, and the edge of the foil is formed in appearance. If it is serious, it will be Fine wrinkles will form.

The wrinkling of the pole piece is related to the compaction density of the pole piece. The greater the compaction density, the more serious the wrinkle will be. Wrinkling is also related to the material of the current collector. The thinner the base material, the more obvious the wrinkled foil phenomenon, and it is not easy to adjust. This is also the reason why it is difficult to use aluminum foil below 12 μm in the market.

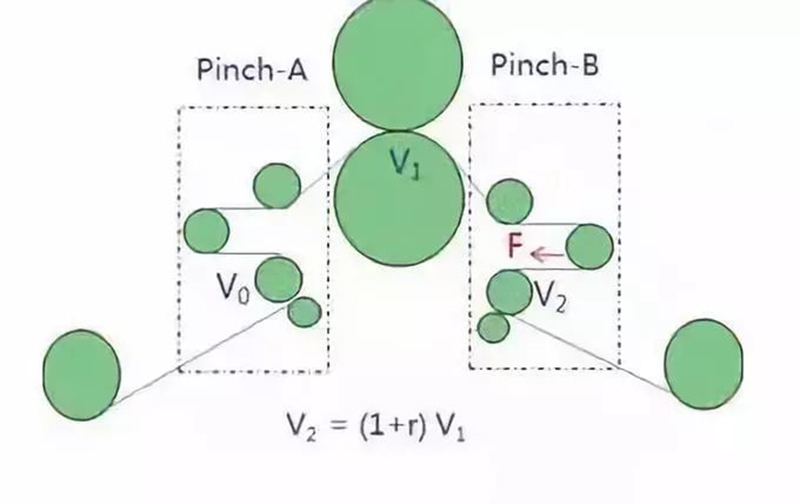

In addition, the inconsistency of the transverse surface density and longitudinal surface density of the coating will also increase the degree of wrinkling of the pole piece. When the surface density is inconsistent, the stress of the pole piece will be inconsistent, and the surface of the pole piece will be uneven after the stress is released. When the roller of the llithium battery roller press is worn, the roller surface will form a concave shape, and the compaction density at the middle of the pole piece will be inconsistent with the compaction density at the edge of the pole piece, and the extension will be inconsistent, so wrinkling will occur. The local position of the roll is worn due to abnormal reasons, and the surface of the pole piece will also be uneven after being rolled.

In addition to the above reasons, there are non-parallel rollers, uneven tension, and excessive alignment of the single and double sides of the coating, which will also cause the pole piece to wrinkle. Uneven winding tension will cause wavy edges of the pole piece, non-parallel passing rollers will cause tab folds, coating single-sided and double-sided alignment exceeding the limit will affect the deviation correction device of the roller press, resulting in slight swing of the pole piece, and the rear edge of the overpressure roller The surface density of the position is inconsistent with that of the middle position, resulting in overpressure or wavy edges.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: