-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.com

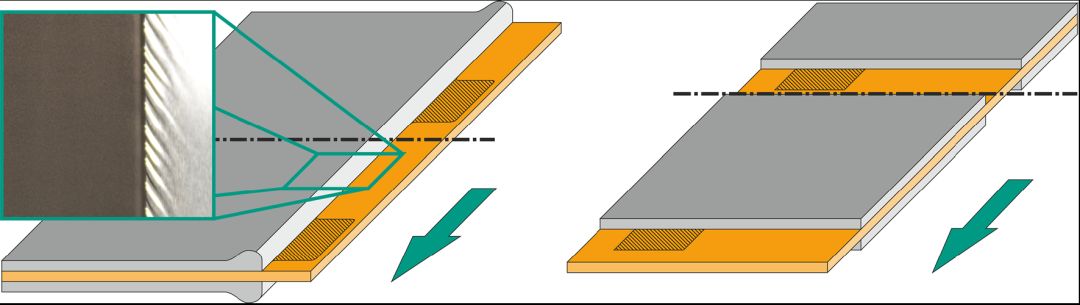

The lithium-ion battery slurry coating process is a process in which a non-Newtonian fluid contacts, flows, and solidifies a solid substrate.Different from the contact between the solid state, the lithium battery slurry is sprayed from the coating head and coated on the copper foil and aluminum foil, and there will be dynamic changes in the liquid state, including adhesion, wetting, leveling, rebound, etc. microscopic changes.Then after a coating oven, after a certain temperature and time baking, it gradually solidifies to form the electrode plate of the lithium battery.During these short-time dynamic changes, the surface tension has a great influence on the final shape of the pole piece.

The defects caused by surface tension are mainly:

1.thick edge

Thick edge of coating refers to the phenomenon that the thickness is thicker than the thickness in the middle at the beginning, the end or the edges of both sides of the coating. This abnormal phenomenon is mainly caused by surface tension.

The thick edge of the coating is abnormal, and the main effect is the abnormal appearance of the pole piece when it is wound.Due to the thicker edge during rolling, the aluminum foil will expand significantly under the same rolling process, resulting in unqualified wrinkles at the rolling tabs.

If the thick edge is serious, the rolling belt will be broken frequently.

(2) Orange peel

Orange peel is also a typical defect in the coating process. This defect is mainly reflected in the uneven surface of the electrode plate, which is pitted like orange peel, which can be observed with the naked eye and has a poor appearance.

In the understanding of battery performance, the positive and negative electrode battery materials attached to the surface of the substrate are not uniform in thickness, which is reflected in the fact that if there are pits in the negative electrode, it is easy to precipitate lithium.

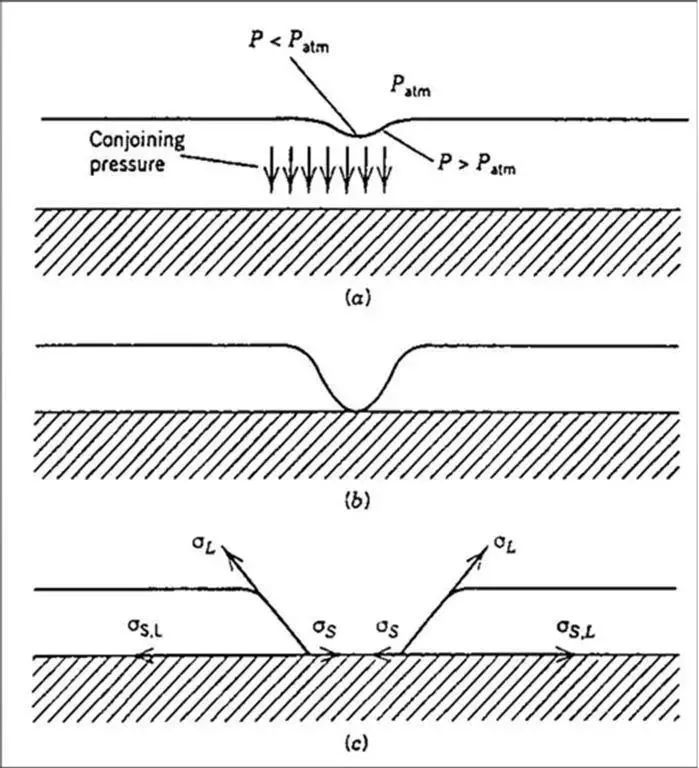

The mechanism of the orange peel defect is that after the lithium battery slurry is coated on the substrate, due to the different surface tension of the pole piece, the liquid will flow internally under the drive of tension. As the pole piece passes through the battery oven, it gradually dries.

As the liquid dries and solidifies in the flow, the phenomenon of unevenness will appear.

In order to prevent the appearance of orange peel defects, it is necessary to pay attention to the baking rate to reduce the rapid drying of the pole piece in the state of wet film,

Because the slurry at this time is still in the process of flow adjustment, reducing the baking rate or adding surfactants can effectively reduce the occurrence of orange peel defects.

(3) Pinholes and pits

The formation mechanism of pinhole and pit defects caused by surface tension is dust, impurities, etc. in the substrate or slurry.

If dust and impurities exist in the slurry, the surrounding liquid will migrate to the outside under the action of surface tension, forming shrinkage hole point defects.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: