-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.comThe principle of ultrasonic metal welding is a special method of using the mechanical vibration energy of ultrasonic frequency to connect the same metal or dissimilar metal. When the metal is ultrasonically welded, it neither transmits current to the workpiece nor applies a high temperature heat source to the workpiece, but under static pressure, the frame vibration energy is converted into friction work, deformation energy and limited temperature rise between the workpieces.The metallurgical bond between the joints is a solid-state welding realized without the base metal melting.Therefore, it effectively overcomes the phenomenon of spatter and oxidation during resistance welding.

Ultrasonic metal welding machine can perform single-point welding, multi-point welding and short-strip welding of copper, silver, aluminum, nickel and other non-ferrous metal filaments or sheet materials.It can be widely used in the welding of thyristor leads, fuse pieces, electrical leads, lithium battery pole pieces and tabs.

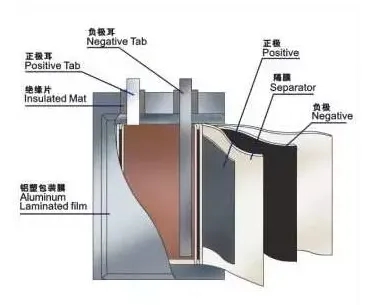

In lithium battery technology, there are three metal welding methods involved: copper/aluminum foil to tab (foil to tab), tab to tab, tab to bus. Among them, copper foil/aluminum foil is the most difficult to solder to the tabs.

Because the two ends of the metal welding use metals of different thicknesses and materials, one end (tab) is relatively thick (eg 0.2mm), and the other end is composed of multiple layers of extremely thin metal sheets.

Among them, the welding of the foil to the tab is to connect all the cathode and anode foils inside the battery to the corresponding tab, so as to transfer the internal energy of the battery to the outside. Hundreds of lithium battery cells make up a typical lithium battery pack. The battery cells are combined in series or in parallel. If one connection fails, the output of the entire battery pack will fail. Therefore, a robust and firm connection is crucial.

The connection of the multilayer foil to the tabs is by ultrasonic metal welding (UMW). UMW is ideal for welding between dissimilar metallic materials such as copper, aluminum and nickel. The two metal parts are compressed by pressure and vibrate relatively with ultrasonic high frequency (usually 20Khz-40Khz). The heat generated by friction can eliminate oxides and contaminants on the metal surface, and at the same time, the two form a "smooth" metal surface. At this point, under the right pressure and heat, a weld is formed between the two.

This process has several advantages. Since it is a solid state process, it adapts to the combination of different materials and avoids the generation of metallic compounds. Ideal for welding between highly conductive materials such as copper plated materials. The whole process does not require high power, and the welding cycle is very short, only a fraction of a second. Multiple layers of thin materials can be welded in one operation.

Compared to Resistance Spot Welding (RSW) and Laser Beam Welding (LBW), Ultrasonic Metal Welding (UMW) is a more ideal joining process for Li-ion battery applications.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: