-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.com

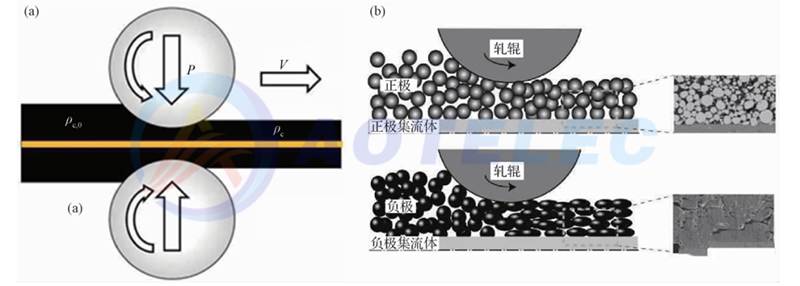

In the production process of lithium batteries, the compaction density has a great influence on the battery performance.Generally speaking, the compaction density is closely related to the specific capacity, efficiency, internal resistance, and cycle performance of the battery.the greater the compaction density, the greater the degree of extrusion between the material particles, the smaller the porosity of the pole piece, the worse the performance of the pole piece to absorb the electrolyte, and the more difficult it is for the lithium battery material electrolyte to infiltrate. As a result, the specific capacity of the material is low, and the battery's liquid retention capacity is poor.

During the cycle of the battery, the polarization will be large, the attenuation will be large, and the internal resistance will increase significantly.

Therefore, a suitable cathode compaction density can increase the discharge capacity of the battery, reduce the internal resistance, reduce the polarization loss, prolong the cycle life of the battery, and improve the utilization rate of the lithium-ion battery. When the compaction density is too large or too small, it is not conducive to the intercalation and intercalation of lithium ions. So what are the compaction densities that affect the compaction density of the positive pole piece?

The main factors that affect the compaction density of the positive lithium battery material electrode sheet mainly include the following four points:

①Material true density

②Material morphology

③Material particle size distribution

④ pole piece technology.

How to Increase Compaction Density

At present, the methods of improving compaction density mainly start from three aspects: material morphology, material particle size distribution, and pole piece technology. For example, the morphology of the ternary material is prepared into a large single crystal similar to lithium cobalt oxide; the particle size distribution of the ternary material is optimized; the conductive agent with good conductivity is used in the production of the pole piece to reduce the amount of the conductive agent, and the slurry is dispersed at a high speed. Disperse conductive agent and binder evenly, etc.

We are AOTELEC, we not only provide lithium battery equipment and lithium battery materials, but also provide battery knowledge.If you are interested, please contact me.

E-mail:kaka@aotbattery.com

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: