-

Jun , 28 2022

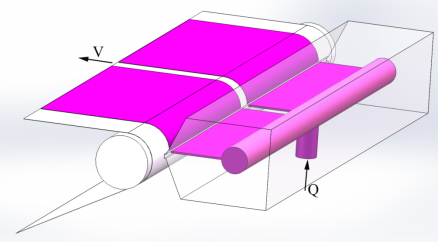

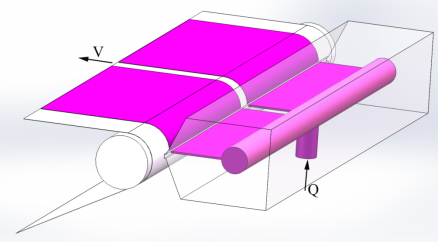

The lithium-ion battery slurry coating process is a process in which a non-Newtonian fluid contacts, flows, and solidifies a solid substrate.Different from the contact between the solid state, the lithium battery slurry is sprayed from the coating head and coated on the copper foil and aluminum foil, and there will be dynamic changes in the liquid state, including adhesion, wetting, leveling, rebo...

View More

-

Jul , 07 2022

The principle of ultrasonic metal welding is a special method of using the mechanical vibration energy of ultrasonic frequency to connect the same metal or dissimilar metal. When the metal is ultrasonically welded, it neither transmits current to the workpiece nor applies a high temperature heat source to the workpiece, but under static pressure, the frame vibration energy is converted into fricti...

View More

-

Aug , 18 2022

The sodium-ion battery mainly includes five parts: cathode electrode material, anode electrode material, battery electrolyte, battery current collector and battery separator. Cathode electrode material Cathode and anode materials affect key performance indicators such as energy density, power density, cycle life, and safety of Na-ion batteries, and are critical to battery performance. The mainstre...

View More

-

Sep , 02 2022

In the production process of pouch cell battery, there are many factors that can lead to abnormal gas production, which can be divided into several categories: First, the film formation of the cell itself is unstable. In the subsequent cycle process, the SEI film on the surface of the negative electrode may fall off or become loose, and the SEI film(SEI Formation Machine) is reconstructed, accompa...

View More

-

Oct , 11 2022

View More

-

Oct , 11 2022

The negative electrode material is made into a negative electrode sheet by mixing, coating, rolling, shooting, and drying.Use a lithium sheet as the positive electrode, assemble it into a button battery for testing, and calculate the gram capacity of the material by testing the capacity of the button battery. Required materials and equipment; Positive powder Electrolyte LB-5275 Carbon black KS-6 A...

View More

-

Nov , 23 2022

There are several types of wrinkling of the lithium battery electrode sheets, the wavy edge of the lithium battery electrode, the wrinkle of the lithium battery electrode, and the wrinkling of the paint area. Of course, there are several degrees of wrinkling severity. Wrinkles in the coating area of the electrode will cause the surface of the bare cell to be uneven, and the stress conce...

View More

-

Sep , 07 2023

During the production process of batteries, there may be fine dust particles and impurities in the air, as well as dust and burrs on the positive and negative electrodes. These factors can easily cause physical contact inside the battery and induce short circuits, greatly affecting its performance. In severe cases, it may even cause the battery cell to fail to charge, resulting in a "dead" battery...

View More

-

Oct , 26 2023

In the manufacturing process of lithium-ion batteries, there are three crucial items that must be strictly controlled:One is dust.The second is metal particles.The third is moisture; Dust and metal particles that are not properly controlled can directly lead to safety accidents such as internal short circuits, fires, and combustion within the battery; If moisture is not effectively controlled, it ...

View More

-

Dec , 05 2023

The current collector is one of the indispensable components in lithium-ion batteries. It can not only carry active substances, but also collect and output the current generated by electrode active substances, which is beneficial for reducing the internal resistance of lithium-ion batteries, improving the Coulombic efficiency, cycle stability, and rate performance of batteries. At present, the pos...

View More

-

May , 09 2024

May , 09 2024

Coating process is a process based on the study of fluid properties, which involves coating one or more layers of liquid onto a substrate. The substrate is usually a flexible film or backing paper, and then the coated liquid coating is dried in an oven or cured to form a special functional film layer. The coating process of lithium-ion power battery electrodes has its own characteristics: d...

View More

-

Jun , 13 2024

Jun , 13 2024

1.Introduction 2.Muffle Furnace 3.Application scope 4.Maintenance and precautions 5.Development History 1.Introduction: Muffle furnace, also known as box type resistance furnace or high-temperature muffle furnace, is a universal heating equipment that can be divided into box type furnace, tube type furnace, and crucible furnace. There are domestic muffle furnaces and imported muffle furnaces ...

View More

May , 09 2024

May , 09 2024

Jun , 13 2024

Jun , 13 2024