-

Jul , 25 2024

Jul , 25 2024

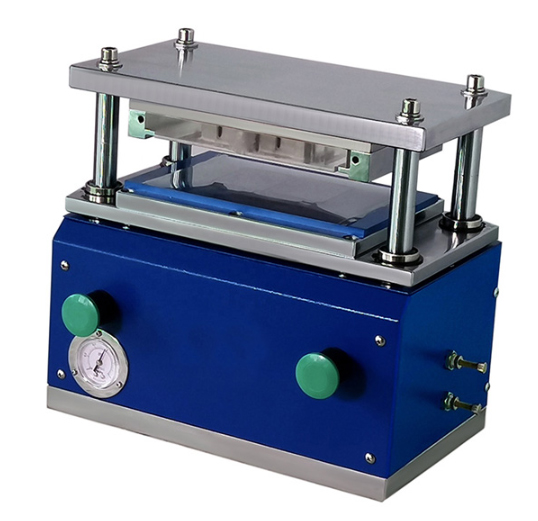

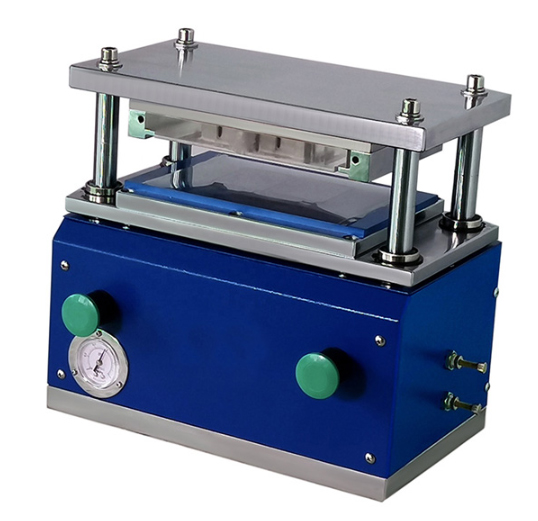

Introduction: The pouch cell battery electrode punching machine plays a crucial role in the production process of pouch cell batteries, particularly in the preparation of electrodes. Its primary function is to precisely punch out electrode materials such as battery cathodes, anodes, and separator sheets into standardized samples or strips, ensuring uniformity and precision for subsequent battery a...

View More

-

Aug , 01 2024

Capacity is the primary attribute of a battery, and insufficient cell capacity is also a common problem encountered during sample and mass production. This article mainly analyzes the problem of no capacity in battery cells. What is the reason for insufficient battery capacity? When hearing that the battery cell capacity is insufficient, the first reaction should be to confirm whether there i...

View More

-

Sep , 19 2024

Sep , 19 2024

In the intricate process of battery manufacturing, the muffle furnace plays a pivotal role, ensuring the quality and performance of the final product. This advanced heating equipment, renowned for its stability, precision, and efficiency, is indispensable in various stages of battery production, particularly in the preparation of key materials and the optimization of their properties. The Role of ...

View More

-

Sep , 26 2024

Sep , 26 2024

In the rapidly evolving landscape of the energy storage industry, pouch cell batteries have emerged as a prominent choice due to their high energy density, exceptional safety features, and flexibility in design. At the core of the manufacturing process of these batteries lies the Aluminum laminated film forming machine, a vital piece of equipment that ensures the precision and efficiency of batter...

View More

-

Oct , 17 2024

Oct , 17 2024

The coin cell punching machine is a specialized piece of equipment designed for the precise and efficient manufacturing of coin cell batteries. These tiny, yet powerful, batteries are ubiquitous in modern electronics, powering devices ranging from watches and calculators to hearing aids and remote controls. The process of creating these batteries involves multiple steps, one of whic...

View More

-

Mar , 21 2025

Mar , 21 2025

Introduction In the heart of every lithium-ion battery lies its electrodes—carefully engineered layers of active materials that determine energy density, cycle life, and safety. The process of transforming raw electrode slurries into uniform, defect-free coatings on metal foils relies on two unsung heroes: doctor blades and coating applicators. These precision tools are pivotal in defining the thi...

View More

-

Apr , 17 2025

Apr , 17 2025

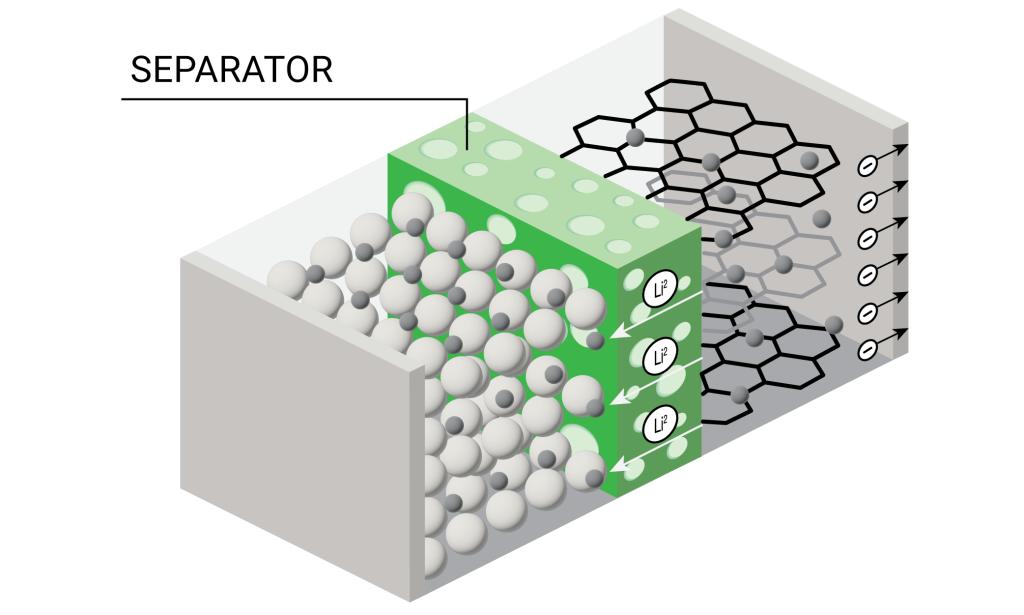

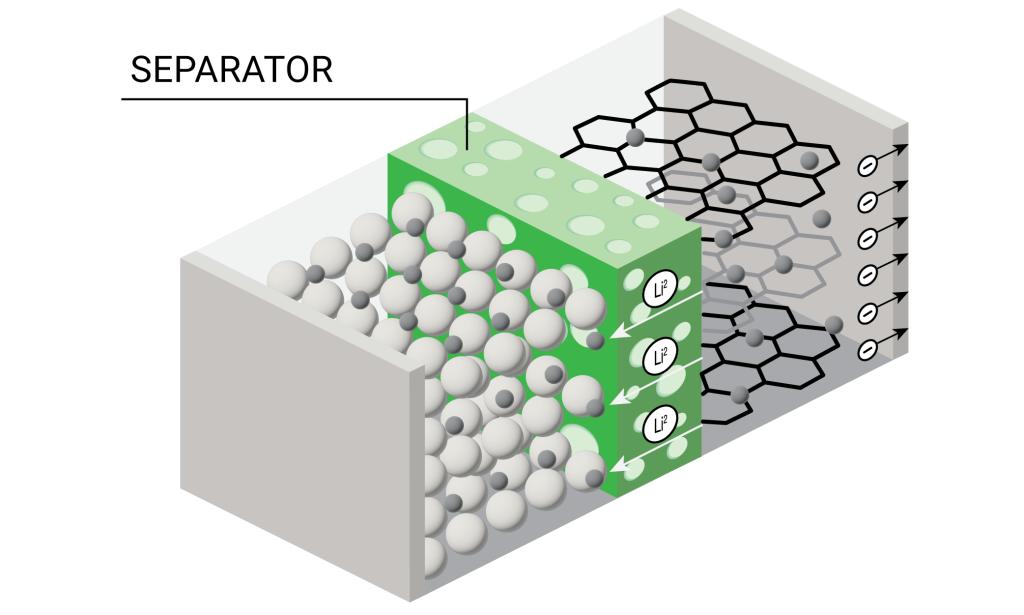

1、The definition and essence of lithium battery separators The lithium battery separator is a thin film material with a microporous structure, located between the positive and negative electrodes of the lithium battery. Its core function is to physically isolate the positive and negative electrodes to prevent direct contact between the two electrodes and cause a short circuit. At the same time, it...

View More

-

Apr , 24 2025

Apr , 24 2025

1. Overview of Battery Coating Machine (1) What is a battery coating machine The battery coating machine, also known as the lithium battery coating machine, is a kind of mechanical equipment specifically used for the production of lithium-ion battery electrode sheets. It evenly coats the slurry on substrates such as aluminum foil or copper foil through a specific coating process. After drying and ...

View More

-

May , 29 2025

May , 29 2025

The performance of the separator is deeply related to the safety of lithium batteries, such as the tensile strength, thermal shrinkage rate, puncture strength, etc. of the separator, which are directly related to the performance of the battery cell. Ceramic coatings, as the most widely used coatings on the market, have the advantages of good stability and low thermal shrinkage. This article will b...

View More

-

Jun , 26 2025

Jun , 26 2025

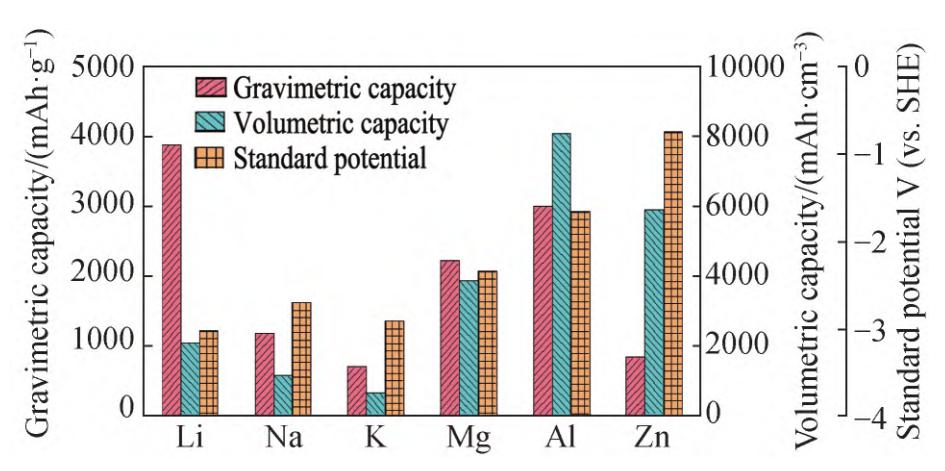

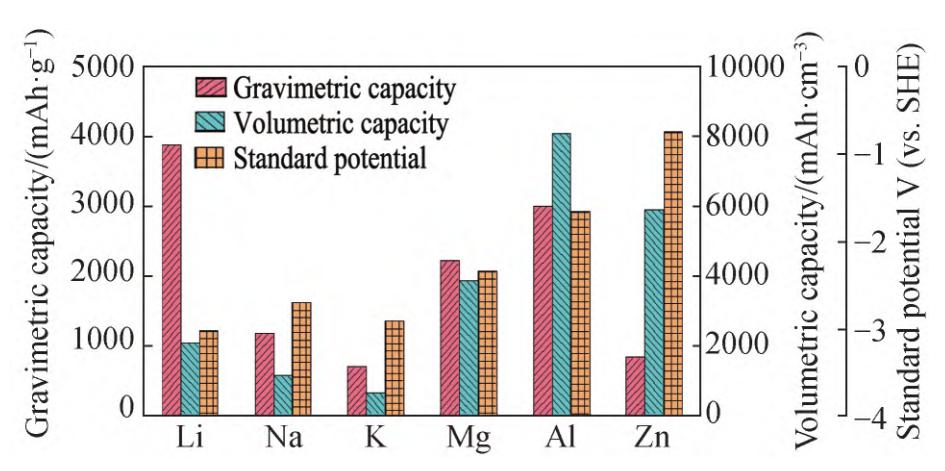

The existing secondary batteries have the characteristics of high energy density and good cycling performance. However, the commonly used organic electrolytes are toxic and flammable, which pose certain safety risks. Moreover, the existing electrode materials are limited in resources and have high costs, restricting their large-scale application in the energy storage field. Using water-based elect...

View More

-

Nov , 14 2025

Nov , 14 2025

In the field of basic lithium-ion battery research, "unrepeatable experimental data and no basis for electrode selection" have long been key pain points plaguing researchers. Recently, a major breakthrough has been achieved in a study focusing on the standardized parameters of glassy carbon electrodes (GCEs) for lithium-ion batteries. After systematically testing GCEs of different specifications r...

View More

-

Dec , 05 2025

Dec , 05 2025

Sodium-ion batteries (SIBs) have emerged as one of the most promising alternatives to lithium-ion batteries (LIBs) for large-scale energy storage and low-cost portable electronics, thanks to sodium’s abundant reserves, low cost, and similar electrochemical behavior to lithium. However, SIBs face critical challenges: the larger ionic radius of Na⁺ (1.02 Å vs. Li⁺’s 0.76 Å) leads to slower ion diffu...

View More

Jul , 25 2024

Jul , 25 2024

Sep , 19 2024

Sep , 19 2024

Sep , 26 2024

Sep , 26 2024

Oct , 17 2024

Oct , 17 2024

Mar , 21 2025

Mar , 21 2025

Apr , 17 2025

Apr , 17 2025

Apr , 24 2025

Apr , 24 2025

May , 29 2025

May , 29 2025

Jun , 26 2025

Jun , 26 2025

Nov , 14 2025

Nov , 14 2025

Dec , 05 2025

Dec , 05 2025