-

Jul , 25 2024

Jul , 25 2024

Introduction: The pouch cell battery electrode punching machine plays a crucial role in the production process of pouch cell batteries, particularly in the preparation of electrodes. Its primary function is to precisely punch out electrode materials such as battery cathodes, anodes, and separator sheets into standardized samples or strips, ensuring uniformity and precision for subsequent battery a...

View More

-

Aug , 01 2024

Capacity is the primary attribute of a battery, and insufficient cell capacity is also a common problem encountered during sample and mass production. This article mainly analyzes the problem of no capacity in battery cells. What is the reason for insufficient battery capacity? When hearing that the battery cell capacity is insufficient, the first reaction should be to confirm whether there i...

View More

-

Aug , 22 2024

Aug , 22 2024

The battery electrode slitting machine is a specialized piece of equipment designed for the precise and efficient cutting of battery electrode sheets into narrow strips, a crucial step in the manufacturing process of lithium-ion and other types of batteries. These machines play a pivotal role in ensuring the quality and performance of the final battery product by accurately controlling the width, ...

View More

-

Jan , 02 2025

Jan , 02 2025

Battery manufacturing is a complex and multi-faceted process that involves a series of intricate steps, each requiring specialized machinery to ensure precision, efficiency, and safety. From raw material processing to final assembly and testing, each stage in battery production relies heavily on advanced technology to meet the growing demand for high-performance, reliable, and sustainable energy s...

View More

-

Jan , 16 2025

Jan , 16 2025

1、the unique characteristics of sodium metal chips Sodium metal chips is a kind of energy storage material with sodium metal as the main component. Compared with lithium metal, sodium metal is more abundant and cheaper in the earth's crust, which makes sodium metal chips have significant economic advantages in the field of energy storage. In addition, sodium metal chips also has the following uniq...

View More

-

Feb , 27 2025

Feb , 27 2025

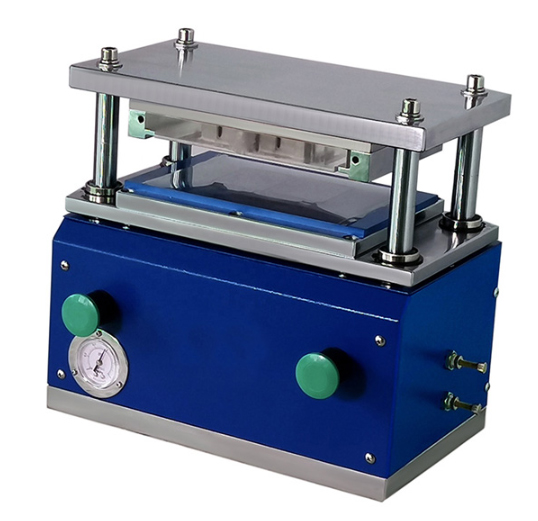

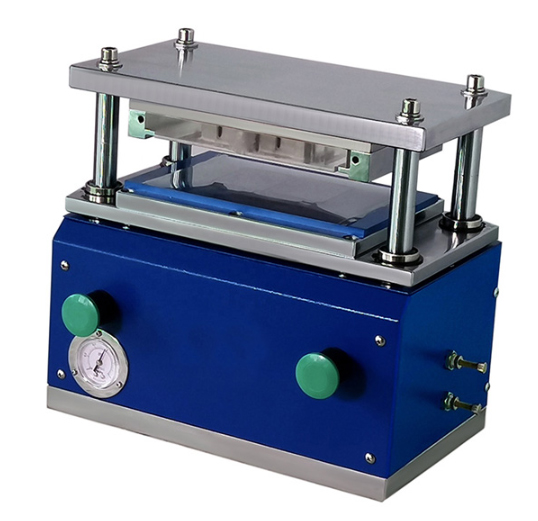

Introduction The rapid growth of lithium-ion battery demand for electric vehicles, consumer electronics, and renewable energy storage has intensified the need for precision manufacturing processes. Among the critical tools enabling high-quality electrode production are manual die cutters—specialized devices designed to cut cathode and anode electrodes into precise shapes for pouch cells. Whil...

View More

-

Apr , 24 2025

Apr , 24 2025

1. Overview of Battery Coating Machine (1) What is a battery coating machine The battery coating machine, also known as the lithium battery coating machine, is a kind of mechanical equipment specifically used for the production of lithium-ion battery electrode sheets. It evenly coats the slurry on substrates such as aluminum foil or copper foil through a specific coating process. After drying and ...

View More

-

Jul , 31 2025

Jul , 31 2025

In the context of rapidly developing energy storage technologies, battery material research faces dual challenges of efficiency and precision. Although traditional coin cell testing methods are widely used, their cumbersome assembly process and non-reusable nature significantly constrain research efficiency. To address these issues, a novel detachable three-electrode test cell has emerged, with it...

View More

-

Aug , 14 2025

Aug , 14 2025

Batteries are key components in modern energy storage systems, widely used in various fields such as electric vehicles, portable electronic devices, and large - scale energy storage. Electrochemical electrolytic cells, as devices that convert electrical energy into chemical energy, have a significant impact on battery research. They can be used to simulate the internal electrochemical processes of...

View More

-

Nov , 14 2025

Nov , 14 2025

In the field of basic lithium-ion battery research, "unrepeatable experimental data and no basis for electrode selection" have long been key pain points plaguing researchers. Recently, a major breakthrough has been achieved in a study focusing on the standardized parameters of glassy carbon electrodes (GCEs) for lithium-ion batteries. After systematically testing GCEs of different specifications r...

View More

-

Nov , 21 2025

Nov , 21 2025

1. Introduction In the lithium-ion battery manufacturing process, the mixing quality of electrode pastes directly affects the electrochemical performance and cycle stability of the battery. Meanwhile, the mixing uniformity of functional materials such as ceramic materials is crucial for their subsequent application effects. Traditional mixing equipment tends to entrap air during operation, resulti...

View More

-

Dec , 26 2025

Dec , 26 2025

Driven by the global "dual carbon" goals, the new energy industry is experiencing explosive growth. As the core energy storage carrier in the sector, lithium batteries rely on refined and efficient production processes to gain a competitive edge in the industry. Electrode processing is a pivotal link in lithium battery manufacturing, directly determining the battery’s energy density, cycle stabili...

View More

Jul , 25 2024

Jul , 25 2024

Aug , 22 2024

Aug , 22 2024

Jan , 02 2025

Jan , 02 2025

Jan , 16 2025

Jan , 16 2025

Feb , 27 2025

Feb , 27 2025

Apr , 24 2025

Apr , 24 2025

Jul , 31 2025

Jul , 31 2025

Aug , 14 2025

Aug , 14 2025

Nov , 14 2025

Nov , 14 2025

Nov , 21 2025

Nov , 21 2025

Dec , 26 2025

Dec , 26 2025