-

Jan , 02 2020

Coin Cell Disc Cutter Machine is mainly used for lab button battery electrode sheet and battery separator round sheet punching, it is compact and precision, the best choice for the university and research institute. How to change the die of this coin cell puncher? Let's check it out: (Please find attached PDF file for more information) 1. Remove the previous die which is equipped on the disc cutte...

View More

-

Feb , 20 2020

Lithium ion Battery Manufacturing Equipment - Battery Electrode Coating Machine Battery electrode coating process is very important for lithium ion battery manufacturing, so, choose a right and qualified battery coating machine is key for making a good battery. If you are looking for coating machine for your laboratory research, we have three choices for you below: 1.Coating device-film applicator...

View More

-

Feb , 26 2020

Battery electrode roller press machine is a necessary battery equipment for lithium ion battery manufacturing in factory and laboratory after coating and heating process. It is for coated battery electrode pressing and calendering, to increasing battery active material density of the battery electrode. How to choose a nice roller press in your laboratory for li-ion battery research? let's go ahead...

View More

-

Apr , 10 2020

Can Carbon Nanotube Be Used for Lithium ion Battery Material? Carbon nanotube is a one-dimensional quantum material with a special structure. It is mainly composed of hexagonal carbon atoms to form several layers to dozens of coaxial round tubes, maintaining a fixed distance between the layers, about 0.34 nanometers, the diameter is generally 2-20 nanometers. As a typical one-dimensional nanostruc...

View More

-

Mar , 18 2022

The uneven coating of lithium iron phosphate batteries not only leads to poor battery consistency, but also relates to issues such as design and use safety. Therefore, the control of coating uniformity in the production process of lithium iron phosphate battery is very strict, and the following items can be tried: 1. Use "linear" conductive agent "Linear" conductive agents are used, mainly VGCF (c...

View More

-

Nov , 01 2022

During the coating process, various defects may occur on the film surface, such as bubbles, fat edges, craters, polygonal depressions, orange peels, etc. Shrinkage cavities are one of the most common problems.The surface depression of the coating film, that is, the shrinkage cavity, is fundamentally caused by the surface tension gradient generated during the film formation. This phenomenon is call...

View More

-

Nov , 23 2022

There are several types of wrinkling of the lithium battery electrode sheets, the wavy edge of the lithium battery electrode, the wrinkle of the lithium battery electrode, and the wrinkling of the paint area. Of course, there are several degrees of wrinkling severity. Wrinkles in the coating area of the electrode will cause the surface of the bare cell to be uneven, and the stress conce...

View More

-

Feb , 20 2023

1. Energy density; Since the density of solid is higher than that of liquid, if the same volume of solid electrolyte is used to replace the lithium battery electrolyte, the weight of the battery will increase, resulting in a decrease in the energy density (wh/kg) of the battery calculated by weight. The energy density of subsequent solid-state batteries will be significantly improved due to the us...

View More

-

Jun , 16 2023

Lithium Battery Electrolyte has a significant impact on the charging and discharging performance (high and low temperature), lifespan (cyclic storage), and temperature applicability of batteries. Suitable solvents need high dielectric constant and low viscosity. Commonly used solvents are alkyl carbonates such as PC and EC, which have strong polarity, high dielectric constant, but high viscosity, ...

View More

-

Oct , 26 2023

In the manufacturing process of lithium-ion batteries, there are three crucial items that must be strictly controlled:One is dust.The second is metal particles.The third is moisture; Dust and metal particles that are not properly controlled can directly lead to safety accidents such as internal short circuits, fires, and combustion within the battery; If moisture is not effectively controlled, it ...

View More

-

May , 30 2024

May , 30 2024

1. Introduction 2. Overview of battery coating machine 3.Design and Manufacturing of Battery Coating Machine 4.Application and advantages of battery coating machine 5.Development Trends and Future Prospects 1、 Introduction The battery coating machine plays a crucial role in the battery manufacturing process, and its importance and role are mainly reflected in the following aspects: (1)Improving ba...

View More

-

Jul , 25 2024

Jul , 25 2024

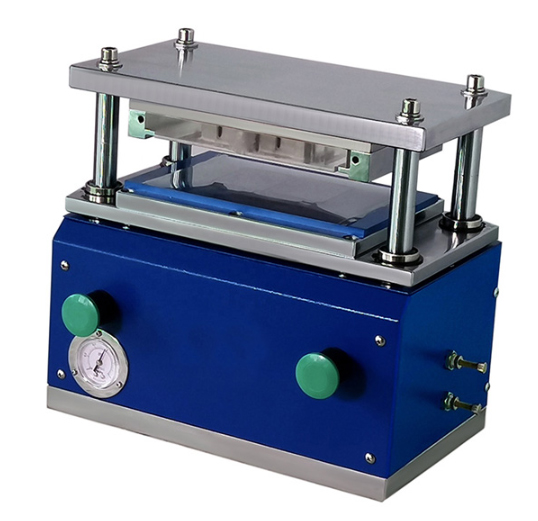

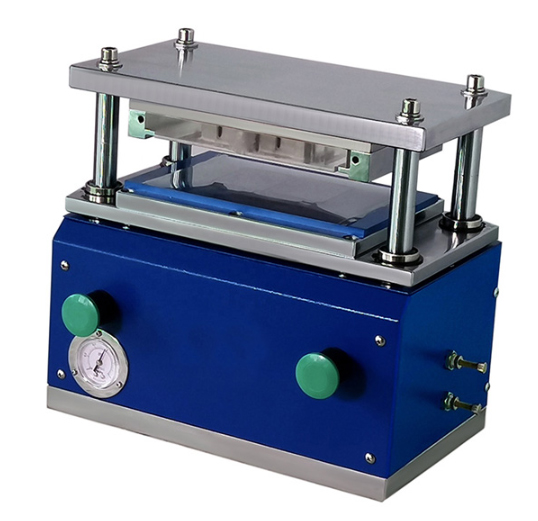

Introduction: The pouch cell battery electrode punching machine plays a crucial role in the production process of pouch cell batteries, particularly in the preparation of electrodes. Its primary function is to precisely punch out electrode materials such as battery cathodes, anodes, and separator sheets into standardized samples or strips, ensuring uniformity and precision for subsequent battery a...

View More

May , 30 2024

May , 30 2024

Jul , 25 2024

Jul , 25 2024