-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.comThe internal impedance consists of the following parts

Ionic Resistance

① Electrolyte inside the battery separator

Influencing factors: electrolyte conductivity, battery separator area, thickness, porosity, tortuosity coefficient (Gurley).

② Electrolyte inside the battery anode material

Influencing factors: electrolyte conductivity, positive electrode thickness, thickness, porosity, tortuosity coefficient.

③ Electrolyte inside the battery cathode material

Influencing factors: electrolyte conductivity, positive electrode thickness, thickness, porosity, tortuosity coefficient.

Electronic resistance

① Active substances of two electrodes

Influencing factors: electrode conductivity, thickness and area

② Fluid collection (copper foil and aluminum foil)

Influencing factors: thickness, width and length of fluid collection, number and position of pole lugs

③ Lead wire (aluminum Tab , nickel Tab , internal conductive connection element)

Influencing factors: overall dimension, conductivity

Contact resistance between active substance and fluid collector

Positive material and aluminum foil, negative material and copper foil.

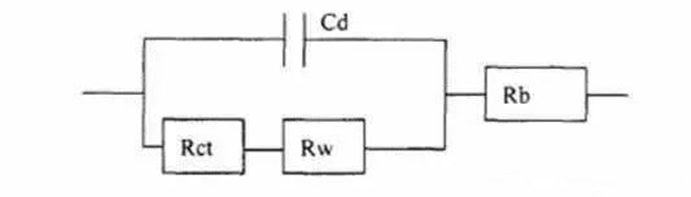

Make an equivalent circuit diagram of the electrode, which is mainly composed of ohmic impedance Rb, double-layer capacitance Cd, electrochemical reaction impedance Rct and diffusion resistance Rw. In the process of lithium ion insertion and removal cycle, the change of Rb value is generally small, while the change of Cd and Rct is relatively obvious.

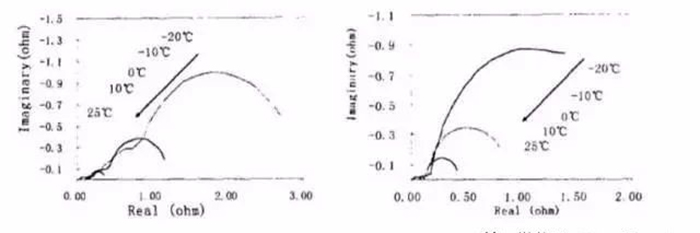

The battery impedance is mainly reflected in the electrochemical reaction impedance, while the ohmic impedance is relatively small. With the decrease of temperature, the impedance of the battery gradually rises, and when it drops to 0 ° C, the impedance speed increases, and the cathode impedance presents a similar trend. From the numerical point of view, the impedance of the battery mainly comes from the contribution of the cathode impedance.

In fact, during the whole cycle of the battery, the impedance of the cathode occupies the main part of the impedance of the whole battery, which is only slightly smaller than the impedance of the whole battery. With the progress of the charge-discharge cycle, the impedance of the cathode increases, and the impedance of the battery also increases. Therefore, special attention should be paid to the cathode resistance test (resistance tester) in the process of electrode fabrication, and the electrode sheet resistivity is particularly important.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: