-

Oct , 11 2022

The negative electrode material is made into a negative electrode sheet by mixing, coating, rolling, shooting, and drying.Use a lithium sheet as the positive electrode, assemble it into a button battery for testing, and calculate the gram capacity of the material by testing the capacity of the button battery. Required materials and equipment; Positive powder Electrolyte LB-5275 Carbon black KS-6 A...

View More

-

Nov , 23 2022

There are several types of wrinkling of the lithium battery electrode sheets, the wavy edge of the lithium battery electrode, the wrinkle of the lithium battery electrode, and the wrinkling of the paint area. Of course, there are several degrees of wrinkling severity. Wrinkles in the coating area of the electrode will cause the surface of the bare cell to be uneven, and the stress conce...

View More

-

Apr , 11 2023

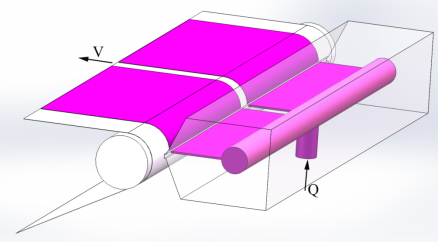

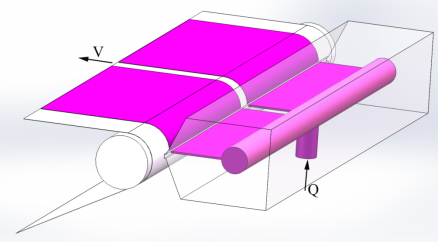

The micro-gravure coating method uses a gravure roll, the gravure roll surface is mounted on bearings, partially immersed in the feed pan, and the rotating shaft picks up the coating, After quantification by a flexible rigid scraper, the coating liquid is taken away by the reverse motion substrate to achieve uniform thin layer coating. The direction of rotation of the microgravure coating gravure ...

View More

-

May , 12 2023

During the mixing machine, transportation, and coating processes of the mixer, foreign objects such as dust or long flocs are mixed into the coating liquid or fall onto the wet coating surface,The surface tension of the coating at this location is affected by external forces, resulting in a change in intermolecular forces. The slurry undergoes a slight transfer, and after drying, a circular mark i...

View More

-

Jan , 03 2024

The emerging "lithium battery electric ships" will become the preferred choice for short distance transportation ships, sightseeing ships, ferries, etc. in inland rivers and lakes due to their advantages of green environmental protection, zero pollution, safety, and low operating costs. As the safest iron phosphate lithium battery in the lithium battery family, with the breakthroughs in safety, lo...

View More

-

Apr , 25 2024

With the rapid development of technology, the application of lithium batteries in the energy field is becoming increasingly widespread. From smartphones and electric vehicles to large-scale energy storage systems, their efficient and environmentally friendly characteristics have been widely recognized. The lithium battery coating machine, as a key equipment in the lithium battery manufacturing pro...

View More

-

May , 09 2024

May , 09 2024

Coating process is a process based on the study of fluid properties, which involves coating one or more layers of liquid onto a substrate. The substrate is usually a flexible film or backing paper, and then the coated liquid coating is dried in an oven or cured to form a special functional film layer. The coating process of lithium-ion power battery electrodes has its own characteristics: d...

View More

-

May , 17 2024

May , 17 2024

1. Introduction 2. Types and configurations of battery roller machines 3. Operation steps of battery roller machine 4. Safety precautions 5. Application range 1. Introduction In the battery manufacturing industry, batteries play a crucial role in rolling machines. It is mainly used for rolling, compressing, and shaping battery electrodes to ensure uniform distribution ...

View More

-

May , 30 2024

May , 30 2024

1. Introduction 2. Overview of battery coating machine 3.Design and Manufacturing of Battery Coating Machine 4.Application and advantages of battery coating machine 5.Development Trends and Future Prospects 1、 Introduction The battery coating machine plays a crucial role in the battery manufacturing process, and its importance and role are mainly reflected in the following aspects: (1)Improving ba...

View More

-

Jun , 06 2024

Jun , 06 2024

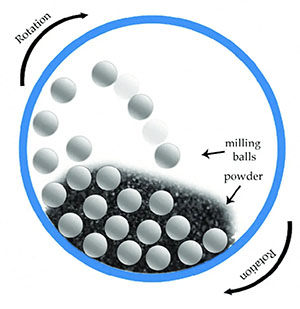

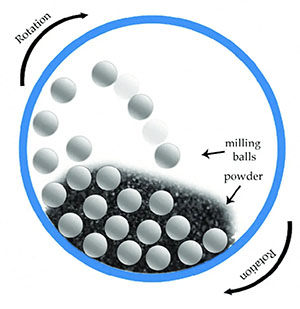

In recent years, the competition to create more sustainable and efficient battery technologies has accelerated due to the growing demand for electric vehicles and renewable energy storage systems. The University of Birmingham in the UK has conducted research on the mechanism of ball milling technology in the manufacturing process of battery materials, and its research findings may help with more e...

View More

-

Jun , 13 2024

Jun , 13 2024

1.Introduction 2.Muffle Furnace 3.Application scope 4.Maintenance and precautions 5.Development History 1.Introduction: Muffle furnace, also known as box type resistance furnace or high-temperature muffle furnace, is a universal heating equipment that can be divided into box type furnace, tube type furnace, and crucible furnace. There are domestic muffle furnaces and imported muffle furnaces ...

View More

-

Jul , 04 2024

Jul , 04 2024

I. Introduction II. Functions of Cylindrical Battery Grooving Machine III. Operating Principles of Cylindrical Battery Grooving Machine IV. Applications of Cylindrical Battery Grooving Machine V. Conclusion I. Introduction Brief overview of cylindrical battery technology and its significance in modern energy storage systems. Introduction to the cylindrical battery grooving machine and ...

View More

May , 09 2024

May , 09 2024

May , 17 2024

May , 17 2024

May , 30 2024

May , 30 2024

Jun , 06 2024

Jun , 06 2024

Jun , 13 2024

Jun , 13 2024

Jul , 04 2024

Jul , 04 2024