-

May , 04 2020

Which equipment is your best choice for lab lithium battery slurry mixing? Lithium battery cell slurry mixing is a mixing and dispersion process. In the entire production process of lithium ion batteries, the impact on the quality of the product is greater than 30%, which is the most important link in the entire production process. So, how to choose a correct equipment for your lab battery researc...

View More

-

Mar , 07 2022

Mar , 07 2022

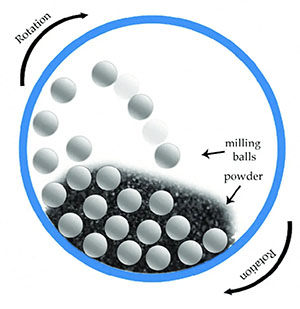

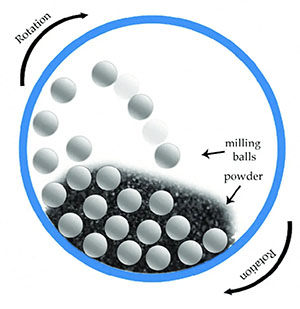

Ball mill is an optimal equipment for battery research institutes, universities and enterprises to obtain battery material particle research samples. Zirconia tank: 1450-1500 degrees, normal work below 100 degrees, except for special requirements, Mohs hardness 9. More suitable materials: 1. Medicine (Chinese medicine or Western medicine), 2. Glass powder, etc., which are widely used, and both met...

View More

-

Jun , 06 2024

Jun , 06 2024

In recent years, the competition to create more sustainable and efficient battery technologies has accelerated due to the growing demand for electric vehicles and renewable energy storage systems. The University of Birmingham in the UK has conducted research on the mechanism of ball milling technology in the manufacturing process of battery materials, and its research findings may help with more e...

View More

-

Sep , 12 2024

Sep , 12 2024

In the realm of battery technology, the refinement and uniform mixing of battery materials play a pivotal role in enhancing battery performance and reliability. Battery material processing ball mills have emerged as essential tools in achieving these goals, offering precise control over material grinding and mixing. This article delves into the intricacies of battery material processing ball ...

View More

Mar , 07 2022

Mar , 07 2022

Jun , 06 2024

Jun , 06 2024

Sep , 12 2024

Sep , 12 2024