-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

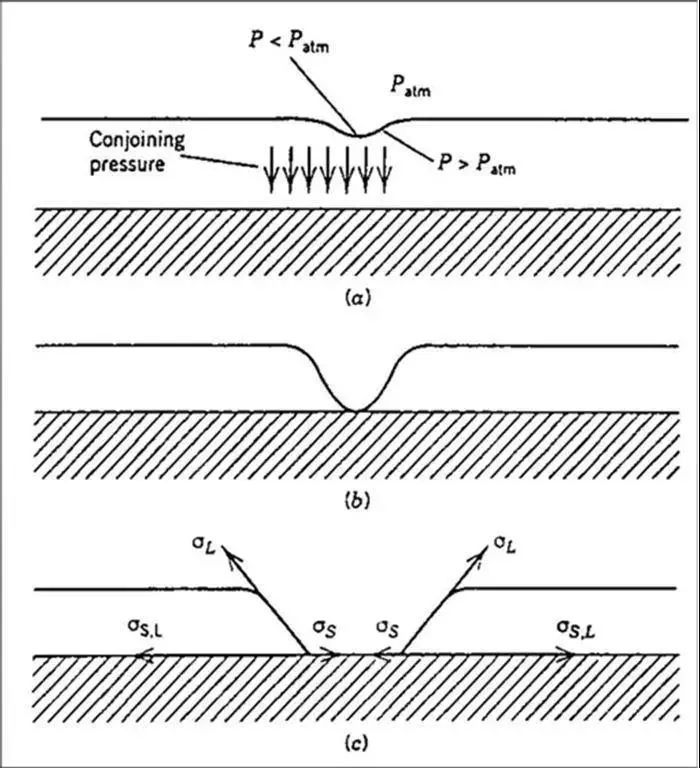

ping@aotbattery.comDuring the mixing machine, transportation, and coating processes of the mixer, foreign objects such as dust or long flocs are mixed into the coating liquid or fall onto the wet coating surface,The surface tension of the coating at this location is affected by external forces, resulting in a change in intermolecular forces. The slurry undergoes a slight transfer, and after drying, a circular mark is formed with a thin center. The process of change is shown in the figure.

Anti foaming measures, combined with the production process of lithium batteries, need to identify all links during the production process where the slurry may mix with foreign objects in order to reduce such bubbles,

For example, raw materials containing foreign objects, improper storage of raw materials mixed with foreign objects, mixing of foreign objects during the mixing and mixing process, mixing of foreign objects during the slurry transportation process, and coating bubbles caused by foreign objects falling into the slurry and wet coating surface in the workshop environment. It is necessary to improve the cleanliness of the workshop environment, strengthen the airtightness of the production process, reduce contact between external foreign objects and coating slurry, and other methods to eliminate coating bubbles, including:

(1) Strictly control the production, packaging, transportation, storage and other processes of raw materials, and prohibit the mixing of foreign objects;Strengthen the inspection of raw materials.

(2) Maintain the cleanliness of the mixing workshop. Adopting automatic feeding equipment to reduce personnel participation in the feeding process; The personnel and material channels in the mixing workshop should be arranged separately.

(3) The mixed slurry machine must not be exposed to external environments and must be sealed for storage.

(4) The mixing and battery coating machine workers shall wear dustproof clothing in accordance with the dress code, and use dust-free and dust-free labor protection equipment such as dust-free cloth and rubber gloves for operation.

(5) The cleanliness of the environment around the coating machine should meet the standard to prevent foreign objects from falling onto the wet coating surface, including the following points: the coating machine head material slot should be covered with a protective cover to prevent foreign objects from falling into the material; The interior and inlet and outlet air ducts of the coating machine oven should be regularly cleaned and dusted; The inlet air of the coating machine must be strictly filtered and the filter element should be replaced regularly; A one-way valve should be installed at the air outlet of the coating machine to prevent external pollution sources from flowing back into the coating machine oven during shutdown.

(6) When increasing the exhaust air volume of the coating drying oven, a large number of coating bubbles will suddenly appear. The reason is that there is a lot of dust accumulation in the inlet and outlet air ducts of the coating oven, which is difficult to clean. Increasing the air volume will blow the accumulated dust into the oven and fall on the wet coating, generating a large number of coating bubbles. The defoaming measures include: firstly, regular dust removal of the oven air duct; 2、Solidify the air volume data of the oven in the process file, and unauthorized personnel are not allowed to adjust it arbitrarily. In actual production, once bubbles appear, they can be eliminated one by one according to the above measures. Only by implementing multiple measures comprehensively and continuously can the bubble scrap rate on the production site be continuously reduced, thereby improving product quality and reducing production costs.

Causes of Bubbles in Negative Electrode Materials of Lithium Batteries and Measures for Defoaming

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: