-

Oct , 11 2022

View More

-

Oct , 11 2022

The negative electrode material is made into a negative electrode sheet by mixing, coating, rolling, shooting, and drying.Use a lithium sheet as the positive electrode, assemble it into a button battery for testing, and calculate the gram capacity of the material by testing the capacity of the button battery. Required materials and equipment; Positive powder Electrolyte LB-5275 Carbon black KS-6 A...

View More

-

Nov , 01 2022

During the coating process, various defects may occur on the film surface, such as bubbles, fat edges, craters, polygonal depressions, orange peels, etc. Shrinkage cavities are one of the most common problems.The surface depression of the coating film, that is, the shrinkage cavity, is fundamentally caused by the surface tension gradient generated during the film formation. This phenomenon is call...

View More

-

Oct , 26 2023

In the manufacturing process of lithium-ion batteries, there are three crucial items that must be strictly controlled:One is dust.The second is metal particles.The third is moisture; Dust and metal particles that are not properly controlled can directly lead to safety accidents such as internal short circuits, fires, and combustion within the battery; If moisture is not effectively controlled, it ...

View More

-

Jul , 11 2024

Introduction Lithium-ion batteries (LIBs) have revolutionized the energy storage landscape, powering everything from portable electronics to electric vehicles and large-scale energy storage systems. At the heart of these batteries lie the cathode materials, which play a pivotal role in determining their performance, safety, and cost-effectiveness. This article delves into the intricacies of LIB ca...

View More

-

Aug , 01 2024

Capacity is the primary attribute of a battery, and insufficient cell capacity is also a common problem encountered during sample and mass production. This article mainly analyzes the problem of no capacity in battery cells. What is the reason for insufficient battery capacity? When hearing that the battery cell capacity is insufficient, the first reaction should be to confirm whether there i...

View More

-

Sep , 12 2024

Sep , 12 2024

In the realm of battery technology, the refinement and uniform mixing of battery materials play a pivotal role in enhancing battery performance and reliability. Battery material processing ball mills have emerged as essential tools in achieving these goals, offering precise control over material grinding and mixing. This article delves into the intricacies of battery material processing ball ...

View More

-

Oct , 17 2024

Oct , 17 2024

The coin cell punching machine is a specialized piece of equipment designed for the precise and efficient manufacturing of coin cell batteries. These tiny, yet powerful, batteries are ubiquitous in modern electronics, powering devices ranging from watches and calculators to hearing aids and remote controls. The process of creating these batteries involves multiple steps, one of whic...

View More

-

Apr , 17 2025

Apr , 17 2025

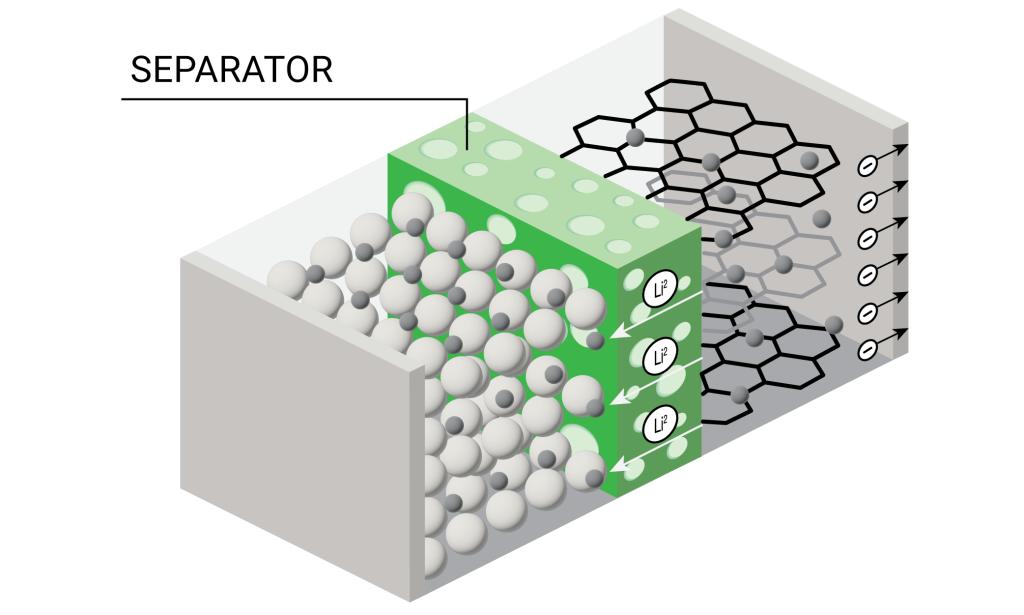

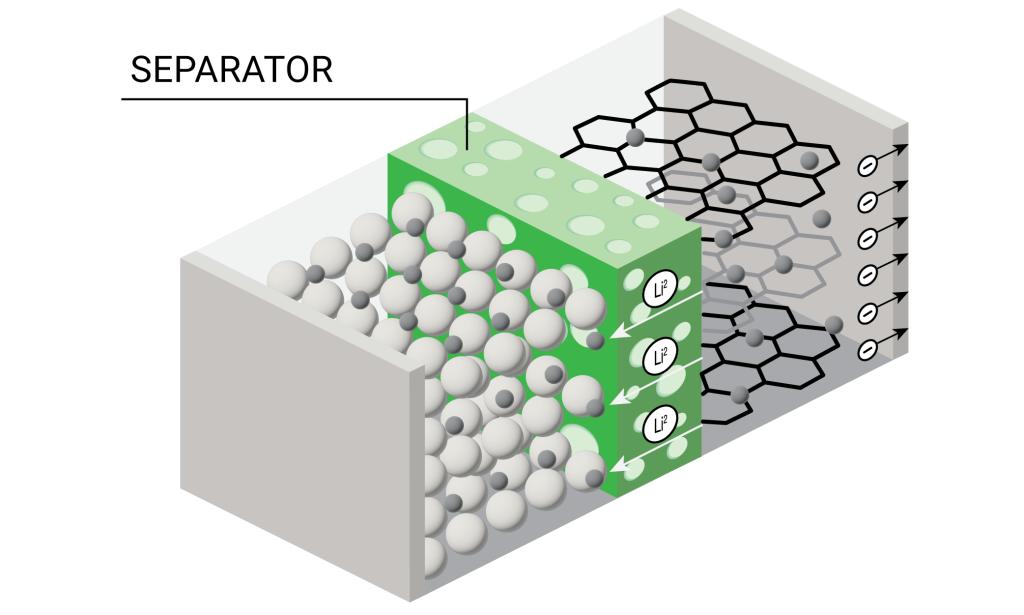

1、The definition and essence of lithium battery separators The lithium battery separator is a thin film material with a microporous structure, located between the positive and negative electrodes of the lithium battery. Its core function is to physically isolate the positive and negative electrodes to prevent direct contact between the two electrodes and cause a short circuit. At the same time, it...

View More

-

May , 29 2025

May , 29 2025

The performance of the separator is deeply related to the safety of lithium batteries, such as the tensile strength, thermal shrinkage rate, puncture strength, etc. of the separator, which are directly related to the performance of the battery cell. Ceramic coatings, as the most widely used coatings on the market, have the advantages of good stability and low thermal shrinkage. This article will b...

View More

-

Jun , 26 2025

Jun , 26 2025

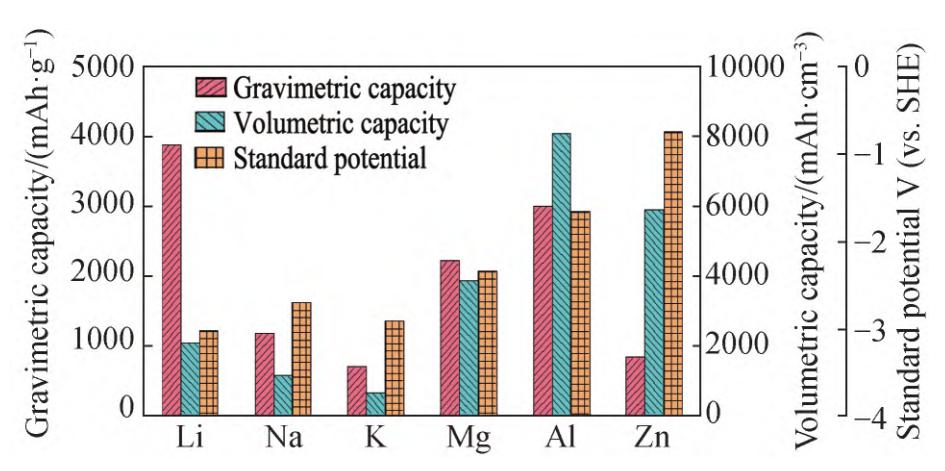

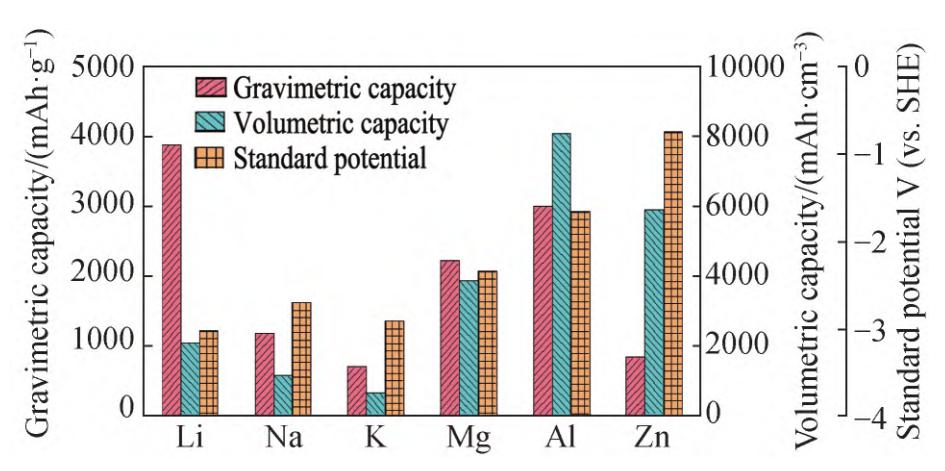

The existing secondary batteries have the characteristics of high energy density and good cycling performance. However, the commonly used organic electrolytes are toxic and flammable, which pose certain safety risks. Moreover, the existing electrode materials are limited in resources and have high costs, restricting their large-scale application in the energy storage field. Using water-based elect...

View More

-

Aug , 14 2025

Aug , 14 2025

Batteries are key components in modern energy storage systems, widely used in various fields such as electric vehicles, portable electronic devices, and large - scale energy storage. Electrochemical electrolytic cells, as devices that convert electrical energy into chemical energy, have a significant impact on battery research. They can be used to simulate the internal electrochemical processes of...

View More

Sep , 12 2024

Sep , 12 2024

Oct , 17 2024

Oct , 17 2024

Apr , 17 2025

Apr , 17 2025

May , 29 2025

May , 29 2025

Jun , 26 2025

Jun , 26 2025

Aug , 14 2025

Aug , 14 2025