-

Call Us

0086-592-7161550 -

Email us

ping@aotbattery.com -

Skype

ping@aotbattery.com

Call Us

0086-592-7161550Email us

ping@aotbattery.comSkype

ping@aotbattery.com

The development of battery technology has revolutionized various industries, ranging from consumer electronics to electric vehicles. One critical aspect of battery production is the electrode roller pressing process, which plays a crucial role in determining battery performance. This article aims to highlight the significance of battery electrode roller pressing and its impact on battery performance.

Battery Electrode Roller Pressing:

Battery electrode roller pressing refers to the process of applying pressure to the electrode materials, effectively compressing them together to form a dense and uniform structure. The primary purpose of this technique is to enhance the performance of the battery by improving the electrode's adhesion, uniformity, and overall conductivity.

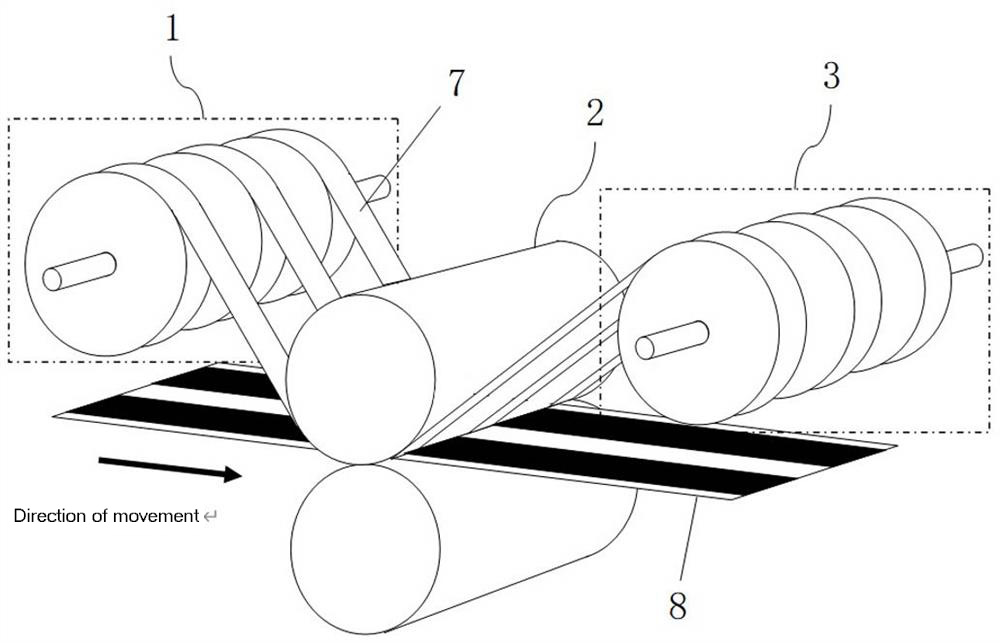

Battery roller press machine, also known as battery roller press or simply roller press, is a specialized industrial equipment used in the production of batteries. It is designed to apply pressure to battery electrode sheets or plates to enhance their performance and overall battery quality.

The machine consists of a set of rollers that exert controlled pressure on the battery electrodes. The electrode sheets, which are typically made of various active materials like lithium cobalt oxide (LiCoO2) or lithium iron phosphate (LiFePO4), are passed through the rollers to compress them uniformly. The pressure applied by the rollers helps to improve the electrode's packing density, thickness uniformity, and contact between layers.

The battery roller press machine plays a crucial role in battery manufacturing processes, as it directly affects the performance and characteristics of the battery. By optimizing the compression parameters, such as pressure, speed, and duration, manufacturers can achieve desired electrode properties like improved energy density, enhanced conductivity, and reduced internal resistance.

The machine offers several advantages. Firstly, it ensures uniform compression across the entire electrode surface, minimizing thickness variations and improving the electrode's structural integrity. Secondly, it promotes better adhesion between active materials and current collectors, leading to improved efficiency in charge and discharge cycles. Lastly, it helps control porosity and pore size distribution, which can have a significant impact on the battery's ion diffusion and overall electrochemical performance.

Roller press machine is an essential tool in battery production, contributing to the optimization of electrode performance and overall battery quality. Its ability to apply controlled pressure enables manufacturers to achieve high-performance battery cells for various applications, such as electric vehicles, portable electronics, and renewable energy storage systems.

Effects on Battery Performance:

1. Enhanced Electrode Adhesion:

During the roller pressing process, the pressure exerted helps in improving the interfacial adhesion between the active materials and the current collector. This increased adhesion minimizes the chances of electrode delamination or detachment, thereby enhancing the battery's structural integrity and reliability.

2. Improved Electrode Uniformity:

Battery electrode roller pressing aids in achieving a uniform density and thickness across the electrode surface. This uniformity ensures consistent current distribution throughout the cell, reducing resistance and enhancing overall energy efficiency. Moreover, it minimizes the formation of "dead spots" or areas with insufficient active material, preventing performance variations within the battery.

3. Enhanced Electrode Porosity Control:

Optimal electrode porosity is crucial for efficient electrolyte penetration and ion transport within the battery. The roller pressing process directly influences the porosity of the electrode by compacting the active material particles. By carefully controlling the roller pressing parameters, it is possible to achieve the desired level of porosity, which directly impacts the battery's power and energy density.

4. Increased Electrode Conductivity:

The electrode roller pressing process not only improves the adhesion between the active material and current collector also enhances the interparticle contacts within the electrode. This results in reduced internal resistance, leading to improved conductivity and overall battery performance.

5. Impact on Battery Cycling Stability:

Battery cycling stability refers to the ability of a battery to maintain its performance over multiple charge and discharge cycles. Proper electrode roller pressing can contribute to enhanced cycling stability by ensuring uniform electrode composition, preventing electrode pulverization, and optimizing electrolyte permeability. These factors collectively promote a more stable and consistent battery performance over time.

Conclusion:

Battery electrode roller pressing has a significant impact on battery performance by enhancing electrode adhesion, uniformity, porosity control, conductivity, and cycling stability. The meticulous optimization of roller pressing parameters can lead to improvements in energy efficiency, power density, and overall battery reliability. As battery technology continues to advance, further research and development in this area will undoubtedly bring about more efficient and reliable energy storage solutions for various applications.

Tel/Whatsapp: 0086-592-7161550

Scan to wechat: